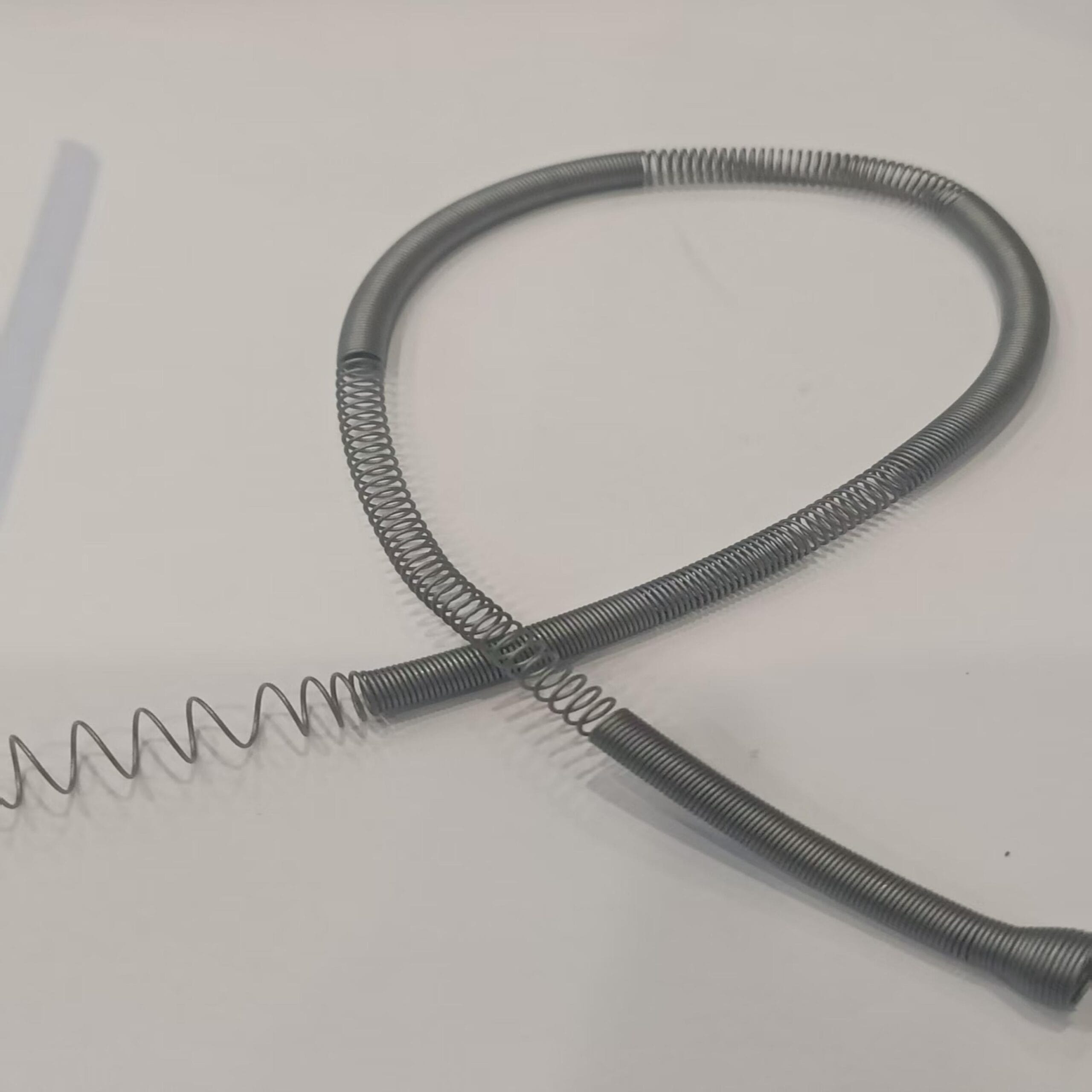

Orthopedic Nitinol Springs – Durable, Flexible Solutions for Advanced Medical Devices

Premium Material Quality for Reliable Nitinol Springs

We manufacture orthopedic Nitinol springs using high-grade nickel-titanium alloy (Nitinol), precisely formulated to deliver exceptional shape memory and superelasticity. Our Nitinol meets stringent ASTM F2063 medical standards, ensuring superior biocompatibility, corrosion resistance, and durability for long-term implantation in the human body.

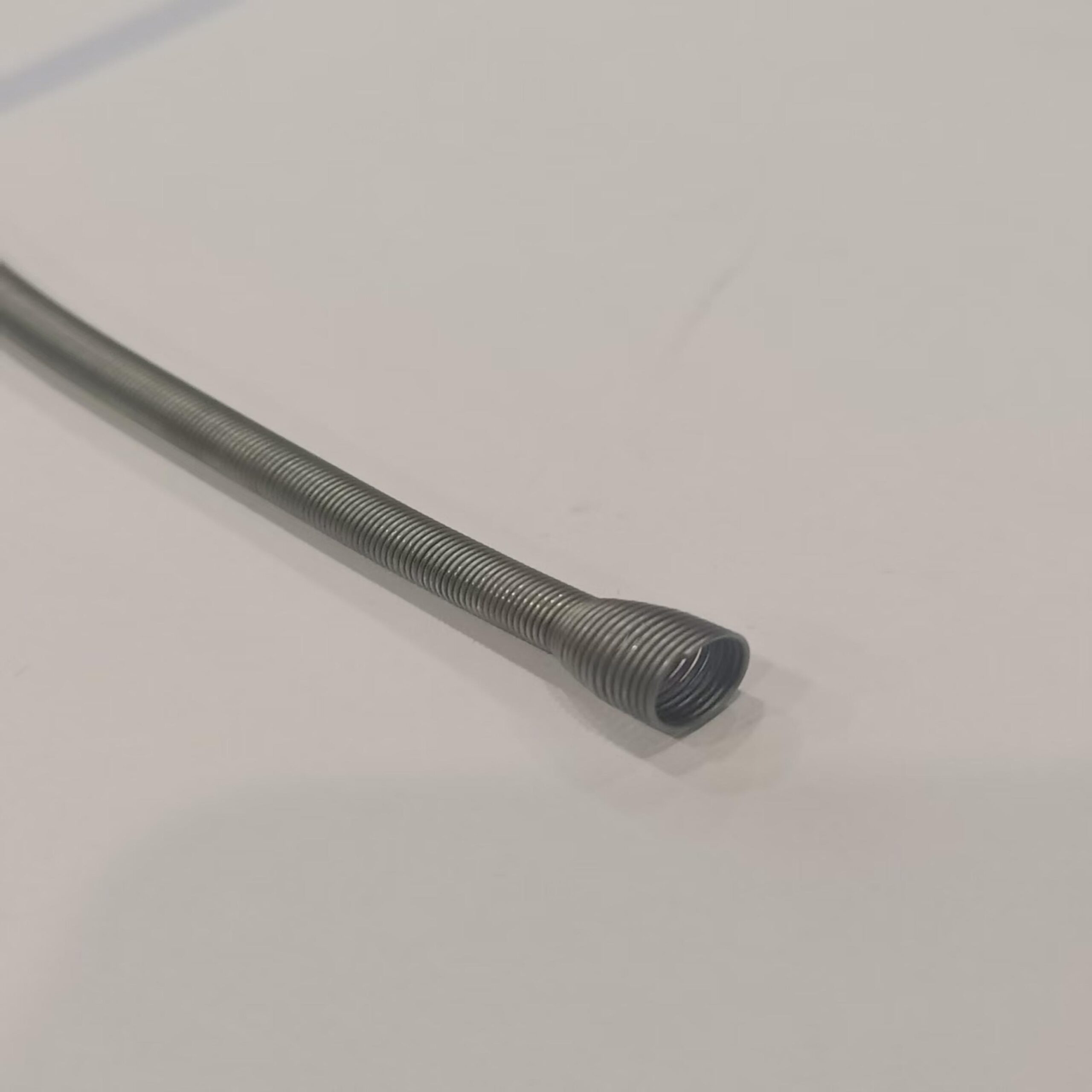

Advanced Surface Finishes to Enhance Spring Performance

To maximize safety and functionality, each Nitinol spring undergoes specialized surface treatments tailored to medical applications:

Electropolishing: Produces an ultra-smooth, contamination-free surface that reduces friction and bacterial adhesion.

Mechanical Polishing: Provides a consistent finish essential for precise force control.

Oxide Coating: Adds a protective barrier, increasing wear resistance under high mechanical stress.

All finishing processes comply with ISO 13485, assuring reliability in orthopedic device manufacturing.

Comprehensive Diameter Range for Versatile Medical Uses

We offer Nitinol springs in a broad diameter range—from 0.1 mm to 5.0 mm—with customization available to precisely match your design requirements.

Micro Springs (0.1–0.5 mm): Perfect for delicate bone positioning and use in minimally invasive surgical tools.

Standard Springs (0.5–2.5 mm): Suited for fracture fixation plates and spinal correction devices.

Large Springs (2.5–5.0 mm): Designed for load-bearing joint reconstruction implants and orthopedic hardware.

Key Medical Applications of Nitinol Springs

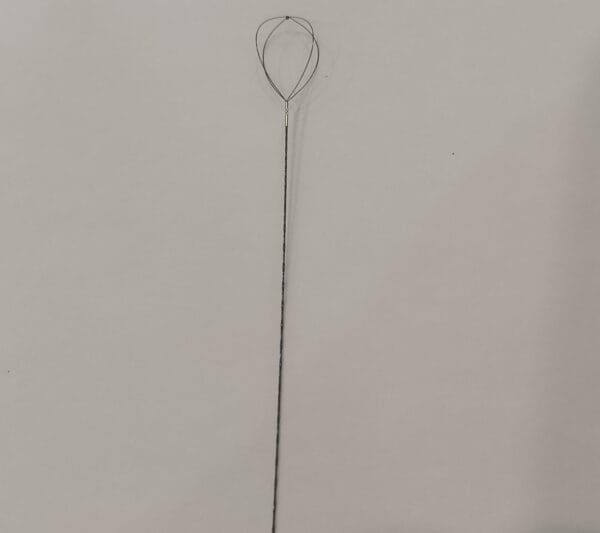

Orthopedic Nitinol springs provide precise, adaptable force for critical medical solutions, including:

Bone Fracture Repair: Stabilizes fractures with controlled compression, supporting natural bone healing.

Spinal Correction Devices: Applies dynamic forces to correct spinal deformities without rigid fixation.

Dental Orthodontics: Gently moves teeth with consistent pressure to minimize discomfort.

Joint Replacement Systems: Absorbs impact forces in hip and knee implants, mimicking natural joint mechanics.

External Fixation Frames: Enables adjustable tension for guided bone growth without invasive surgery.

Why Choose Our Medical-Grade Nitinol Springs?

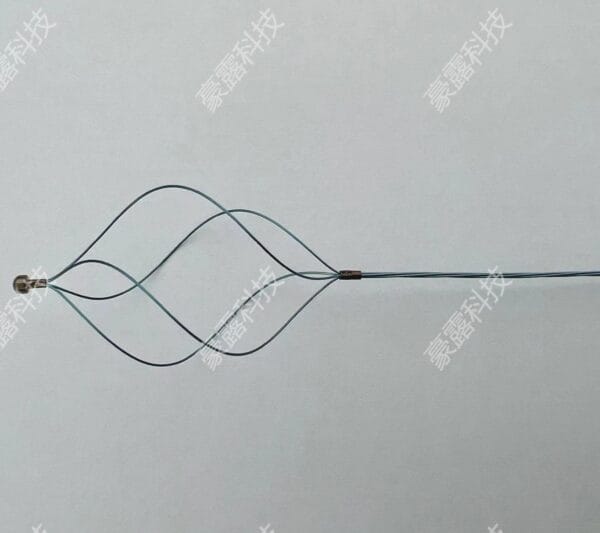

Superior Shape Memory and Superelastic Performance

Nitinol springs reliably return to their original shape after deformation, providing consistent force delivery even under repeated stress—crucial for dynamic orthopedic environments.

Certified Biocompatibility and Sterilization Resistance

Our springs resist corrosion from bodily fluids, prevent nickel ion leaching, and withstand multiple sterilization methods including autoclaving and gamma radiation.

Customization and Precision Engineering

Work with our experts to customize coil count, pitch, diameter, and surface finishes to achieve targeted force output and optimal device integration, including options for laser welding and cladding.

Efficient, High-Quality Production

Utilizing automated cold-forming and heat treatment, we ensure fast, reliable manufacturing with strict quality control on force tolerance, fatigue life, and dimensional accuracy.

Trusted Supplier for Global Orthopedic Innovation

Serving medical device manufacturers and hospitals worldwide, we provide full documentation (material certificates, test reports, RoHS compliance) and dedicated technical support for your Nitinol spring needs.

Ready to innovate? Contact us to develop orthopedic Nitinol springs tailored for your next-generation medical devices—flexible, durable solutions that move naturally with the body.

Reviews

There are no reviews yet.