How to Choose the Right Medical Nitinol Wire

Selecting the appropriate medical nitinol wire for your application depends largely on your temperature requirements. Keep the following key factors in mind:

Activation Temperature: This is the temperature at which the wire begins its shape memory transformation. A wire rated at 40 °C will activate more quickly in hot water compared to an 80 °C wire. For faster response times, opt for a wire with a lower transformation temperature.

Ambient Temperature: Environmental conditions also affect how the wire behaves. In a 30 °C room, a 60 °C wire will revert to its martensitic (soft) state sooner than a 40 °C wire. For applications involving repeated cycling, a higher rated wire may enable shorter recovery times between cycles.

Diameter: Wire thickness plays a critical role in both performance and response time. Thicker nitinol wires exert significantly more force, but they also take longer to heat up and cool down. To balance force with speed, consider using multiple thinner strands instead of a single thick one.

Wire Characteristics

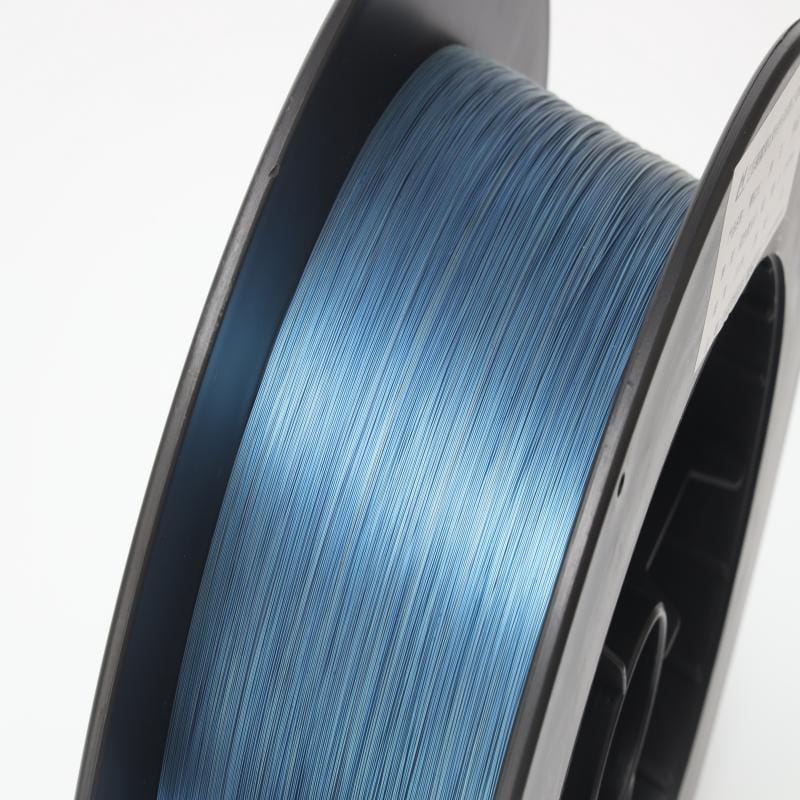

Medical Nitinol wire has a sleek, dark titanium-gray finish, often with a subtle bluish oxide sheen. When cut, its inner core reveals a bright nickel-white center. Known for its durability, nitinol is exceptionally resistant to abrasion and kinking, thanks to its self-healing surface properties.

This material is non-toxic, corrosion-resistant, and requires no special protection against moisture or oxidation. However, overheating poses the greatest risk. If you’re activating the wire electrically, always use a current-limiting circuit to avoid damage. For best performance, monitor the heating process carefully—especially in fast-cycle applications.

Transition Temperatures

Unlike many materials,medical nitinol wire transforms over a range of temperatures rather than at a single fixed point. These transformation characteristics depend on its nickel-to-titanium ratio, impurities, and heat treatment during manufacturing.

All transition temperatures are listed in degrees Celsius. Here’s how different ratings typically behave:

A 40 °C wire will exhibit faster and more forceful activation when heated above its rated temperature—say, in 80 °C water.

At room temperature, an 80 °C wire remains soft and pliable, while a 40 °C wire offers more resistance. A 15 °C wire, in contrast, feels similar to spring steel.

Wires rated at ≤15 °C are highly responsive to even modest heat sources, making them ideal for lower-temperature environments.

Meanwhile, 80 °C wire is engineered to withstand higher temperatures—up to 150 °C—making it suitable for high-heat applications.

Keep in mind that the transformation doesn’t occur instantaneously—it spans a range. Therefore, knowing your operational conditions will help you choose the most effective nitinol wire for your needs.

Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolusa.com

Mid East Region:getnitinol.com

Explore More Nitinol Solutions

Explore More Nitinol Solutions

| Product | Description |

|---|---|

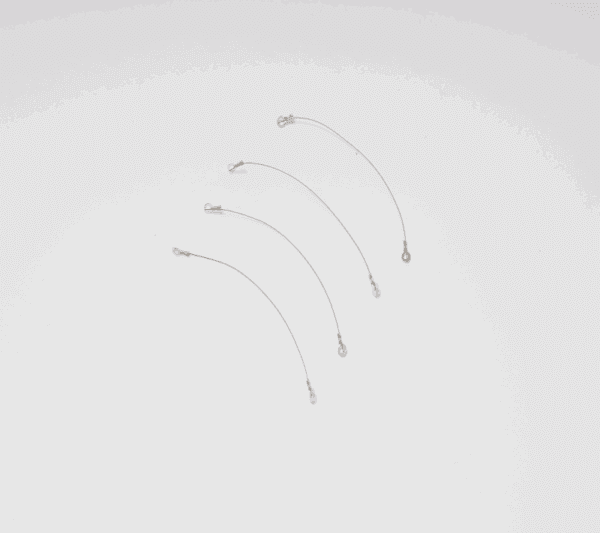

| Nitinol Wire | High-performance shape memory wire |

| Nitinol Tube | Ultra-thin precision tubing |

| Nitinol Rope | Flexible and durable for complex movement |

| Nitinol Guide Wire | Steerable wire for precise medical navigation |

Looking for another Nitinol form factor? We supply a full range of Nickel Titanium components for advanced applications.

Explore More Nitinol Solutions

Explore More Nitinol Solutions

Reviews

There are no reviews yet.