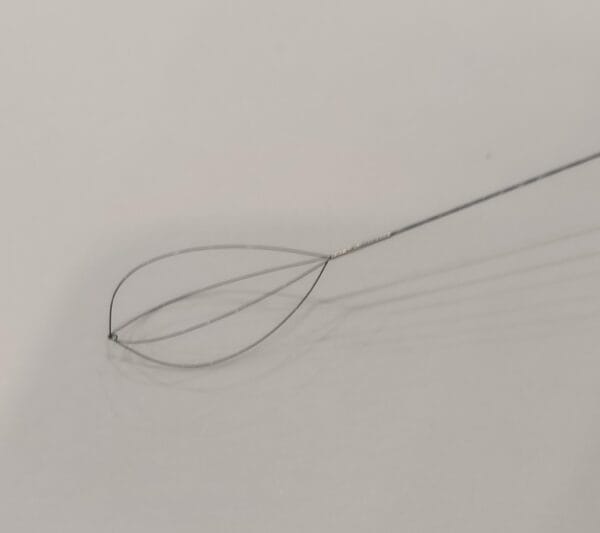

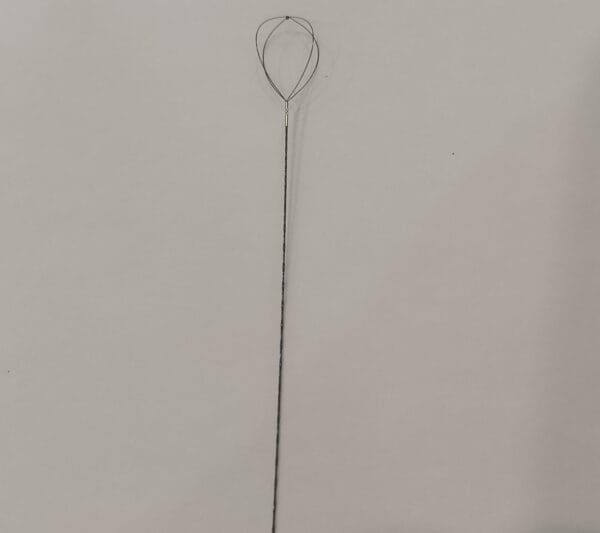

Nitinol Shape Setting for Medical Devices – Precision Wire Passer Solutions

High-Performance Materials for Medical Shape Setting

Our Nitinol Wire Passer is built for nitinol shape setting for medical devices, using top-grade nickel-titanium alloy. This material offers the ideal combination of superelasticity and shape memory properties. Each wire undergoes controlled heat treatment to accurately lock in your device’s required geometry. We only use verified medical-grade raw materials to ensure safety and compliance.

Surface Finishing for Medical Precision

We polish all wires to a smooth, consistent surface optimized for shape setting in medical devices. Finishing options include:

Electropolishing for ultra-clean, corrosion-resistant surfaces

Etching to improve grip during device integration

These finishes ensure excellent biocompatibility and reduced tissue irritation.

Diameter Control for Medical Applications

Our wire diameters range from 0.1 mm to 2.0 mm, with tight tolerances (±0.01 mm) to support precise nitinol shape setting for medical device production. Thin wires are ideal for minimally invasive tools; thicker wires serve structural purposes like stents and support frames.

Applications in Medical Device Manufacturing

These wire passers support complex nitinol shape setting in:

Minimally invasive instruments: Biopsy tools, catheter systems

Implantable devices: Stents, heart valve frames, orthodontic elements

Surgical navigation: Steerable guidewires, neural interface devices

Diagnostic tools: Imaging markers, temperature-sensitive actuators

Expertise in Nitinol Shape Setting for Medical Devices

Industry-Leading Precision

With years of experience in nitinol shape setting for medical devices, we deliver consistent geometries—whether simple curves or complex 3D shapes. We control temperature, stress, and time precisely to avoid common issues like deformation fatigue or incomplete recovery.

Rapid Prototyping and Delivery

Receive prototype wires within 10 business days. Automated shape-setting systems deliver consistent precision with rapid turnaround. Rush services offered to support time-sensitive medical device projects.

Custom Engineering Solutions

Transition temperatures: -20°C to 120°C

Dual-shape memory programming

Radiopaque marker integration or custom color coding

Full-Scale Medical Compliance & Quality Control

ISO 13485-Compliant Manufacturing

All production follows ISO 13485 guidelines, ensuring compliance for FDA submissions and CE marking. Lot-level documentation and full material traceability are standard.

Triple-Tier Quality Checks

Each batch undergoes:

Spectroscopic verification of alloy composition

3D optical scanning to confirm final shape

Fatigue testing of over 10,000 actuation cycles

Competitive Pricing and Free Technical Support

Our efficient batch production and in-house tooling keep costs low. Volume discounts available. You’ll also receive free technical support for:

Wire sizing

Fixture design

Sterilization compatibility (ETO, autoclave, gamma)

Request Samples with Shape Recovery Data

Evaluate our Nitinol Wire Passers risk-free. Request samples with your required shape, finish, and diameter. Each sample includes complete mechanical and shape recovery testing results.

▸ Expert Guidance: 24/7 support via nitinolalloy.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.