Introduction: What Makes Nitinol Strip an Engineering Breakthrough

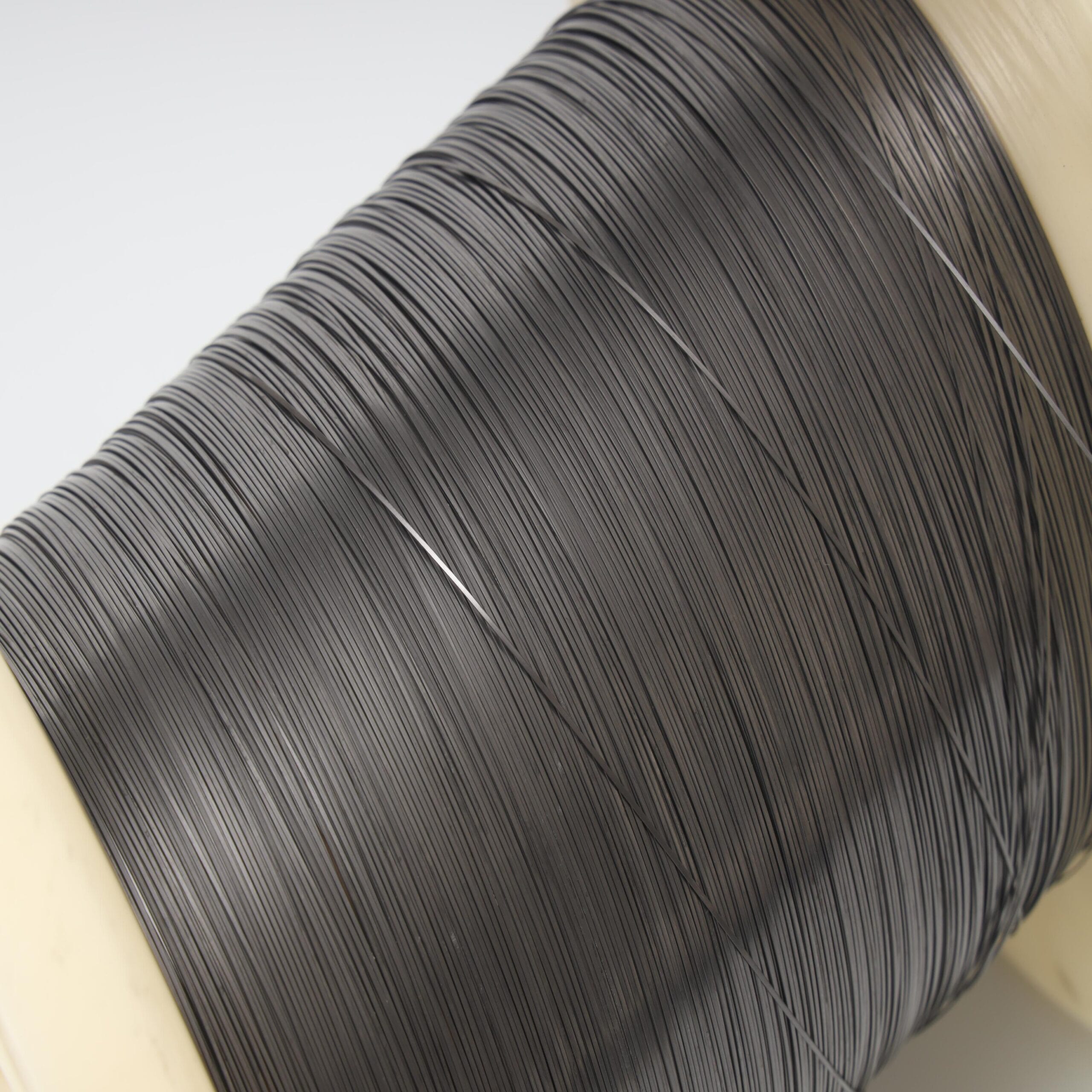

The nitinol strip, a form of nickel-titanium alloy, is reshaping how industries approach performance materials. Known for its shape memory and superelastic properties, this advanced strip material reliably returns to its original form after deformation. Whether used in high-precision mechanical systems or medical implants, nitinol strip enables smart, efficient solutions where traditional metals fall short.

In addition to its thermal responsiveness, it offers exceptional strength, corrosion resistance, and fatigue performance, making it ideal for both industrial and biomedical innovations.

Core Properties of Nitinol Strip and Its Alloys

Shape Memory and Flexibility in Nickel-Titanium Strip

This unique material “remembers” its programmed shape. Once cooled and deformed, it can revert to its original configuration when reheated. This behavior, known as the shape memory effect, is used in systems that require thermal actuation or compact-to-expanded movement transitions.

Superelastic Behavior in Nitinol-Based Strip Materials

Under mechanical stress, the nitinol strip can stretch or bend significantly and instantly recover its original shape once the load is removed. This property, also called pseudoelasticity, is crucial in applications where components undergo repeated flexing or movement.

Damping and Resistivity for Adaptive Systems

The NiTi alloy strip provides excellent damping capacity, reducing vibrations and noise. Simultaneously, its resistivity changes predictably during deformation, making it useful in dynamic sensors or monitoring equipment.

Applications of Nitinol Strip Across Key Industries

Industrial Applications of Shape Memory Strip

In the engineering field, the shape memory strip is found in:

Pipe fittings and thermal couplings

Vibration isolators and adaptive supports

Low-temperature actuated valves

Precision springs and actuators

Because of its durability and reusability, it is now favored in designs demanding long-term consistency under stress.

Nitinol Strip in Aerospace and Automotive Systems

Aerospace and automotive engineers benefit from nickel-titanium strip performance in:

Deployable satellite components (e.g., antennas, solar panels)

Shape-changing components for fluid control

Lightweight heat-responsive mechanisms

These applications rely on the strip’s thermal memory and structural resilience.

Medical Innovations with NiTi Alloy Strip

Due to its biocompatibility and fatigue resistance, NiTi alloy strip is heavily used in:

Cardiovascular devices such as self-expanding stents and filters

Orthodontic elements like archwires and dental spacers

Surgical tools and components for minimally invasive procedures

Artificial joints, sutures, and implantable mechanisms

Its ability to operate reliably inside the human body makes it one of the most sought-after materials in modern healthcare.

FAQs About Our Nitinol Strip Products

What are your working hours?

We operate from Monday to Friday, 9:00 AM – 5:00 PM (Beijing Time).

Please note we are closed during national holidays: May 1–3, October 1–7, and Chinese New Year.

Do you offer free samples of nitinol strip?

Yes, we provide free samples for product evaluation. However, shipping costs must be covered by the buyer.

Which payment methods do you accept?

We support a wide range of payment options, including:

T/T

L/C

D/A

D/P

PayPal

Western Union

MoneyGram

What is your lead time?

For sample orders, the typical lead time is 1–15 business days after payment confirmation.

Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolusa.com

Mid East Region:getnitinol.com

Explore More Nitinol Solutions

Explore More Nitinol Solutions

| Product | Description |

|---|---|

| Nitinol Wire | High-performance shape memory wire |

| Nitinol Tube | Ultra-thin precision tubing |

| Nitinol Rope | Flexible and durable for complex movement |

| Nitinol Guide Wire | Steerable wire for precise medical navigation |

Looking for another Nitinol form factor? We supply a full range of Nickel Titanium components for advanced applications.

Explore More Nitinol Solutions

Explore More Nitinol Solutions

Reviews

There are no reviews yet.