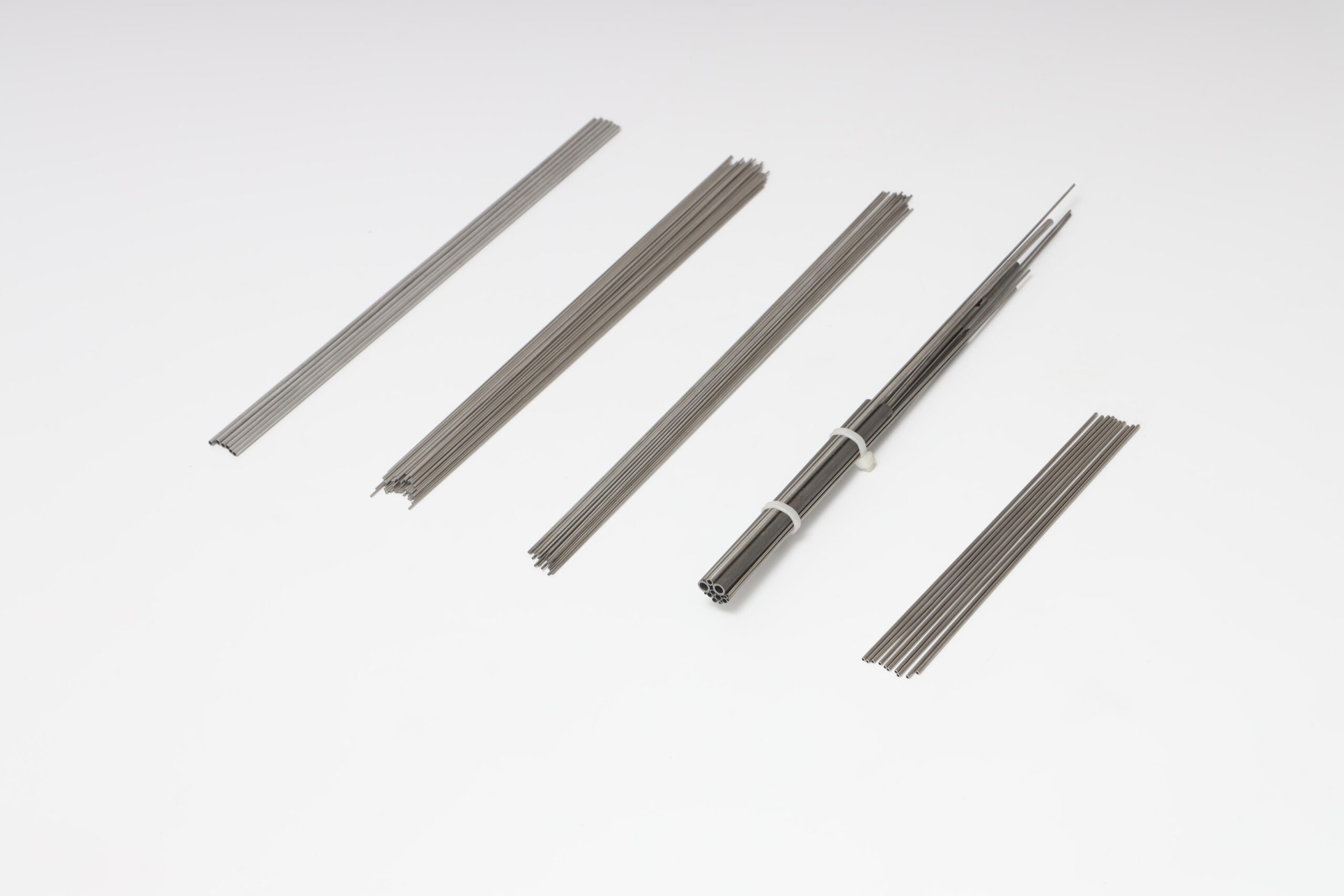

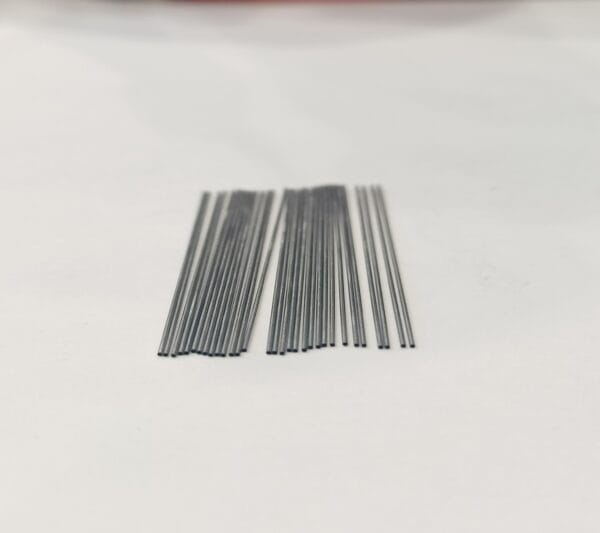

Superelastic Nitinol Tubing for Advanced Applications

Discover the Power of Superelastic Nitinol Tubing—Corrosion-Resistant, Biocompatible, and Built to Last

When performance and durability matter, superelastic nitinol tubing is the ultimate solution. Engineered from a Nickel-Titanium alloy, this advanced material bends, flexes, and instantly returns to its original shape—without permanent deformation. With excellent corrosion resistance and biocompatibility, it’s ideal for demanding medical, industrial, and research applications. Whether navigating blood vessels or operating in corrosive environments, our tubing delivers reliable, long-term performance.

Engineered for Reliability: Corrosion-Resistant Superelastic Tubing

Our superelastic nitinol tubing is manufactured using medical-grade Nitinol alloy. This alloy offers outstanding corrosion resistance, performing reliably in environments such as saltwater, biological fluids, and aggressive chemical exposure.Each tube offers consistent superelasticity and mechanical reliability, making it ideal for both high-performance medical and industrial components.

Surface Finishes That Match Your Application

We provide a range of surface finishes to optimize functionality:

Polished Finish – Ultra-smooth and friction-reducing, ideal for intravascular medical devices.

Etched Finish – Provides a smooth, non-glossy surface ideal for enhancing coating adherence and bonding performance.

Pickled Finish – Oxide-free surface for enhanced cleanliness.

Wide Diameter Range for Versatile Designs

We offer superelastic nitinol tubing in a comprehensive diameter range:

Micro (0.1–1.0 mm OD) – Used in guidewires, micro-catheters

Standard (1.0–5.0 mm OD) –Ideal for use in catheter systems, precision actuators, and sensitive sensor components.

Large (5.0–10.0 mm OD) – For industrial fluid handling and aerospace parts

Custom sizes are available. Contact us with your specific requirements.

Applications of Nitinol Tubing

Medical Devices

Stent delivery systems

Flexible catheters

Neurovascular implants

Orthodontic and endoscopic tools

Industrial and Aerospace Uses

Robotic actuators

Corrosive fluid control

Oil and gas downhole tools

Aerospace vibration damping systems

R&D and Prototyping

Micro-actuators

Smart fluidic systems

Responsive robotic components

Why Choose Our Nitinol Tubing?

High Superelasticity – Excellent flexibility and instant shape recovery

Superior Corrosion Resistance – Long-term durability in harsh environments

Biocompatibility – Meets ISO 10993 & ASTM F2063 for medical use

Fatigue Resistance – Reliable performance under repeated stress

Shape Memory Option – Heat-activated transformation available

Consistent Quality – Certified Nitinol and tight manufacturing tolerances

Surface Versatility – Polished, etched, or pickled to fit your application

Trusted Expertise – Supported by a team with deep Nitinol knowledge

Get Started with Nitinol Tubing Today

Experience the unmatched performance of superelastic nitinol tubing. Combine flexibility, strength, and corrosion resistance in one advanced material. Perfect for medical, industrial, and research innovation.

Contact our team now to request a quote, customize your tubing, and explore how Nitinol can elevate your next breakthrough.

Reviews

There are no reviews yet.