Self Expanding Nitinol Stent: Precision Engineering for Vascular Health

Advanced Material for Superior Performance

Our self expanding nitinol stent is crafted from nickel-titanium alloy (Nitinol), a smart material renowned for its unique combination of superelasticity and shape memory. This ensures the stent flexes seamlessly with natural vessel movements while maintaining robust structural integrity. Thanks to its biocompatible and corrosion-resistant nature, Nitinol guarantees long-term safety and reliability inside the body.

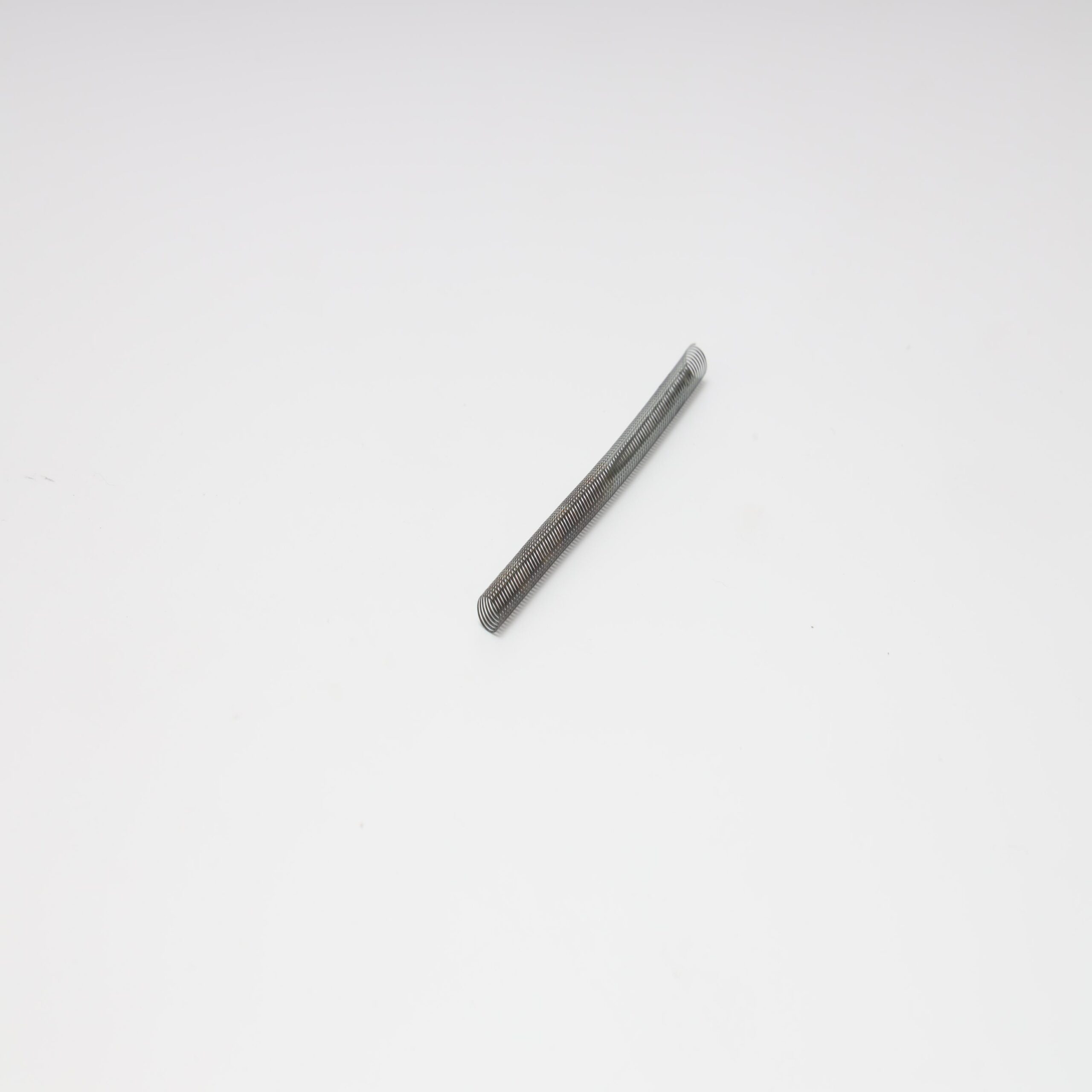

Smooth Surface Finish for Enhanced Healing

Each stent undergoes advanced electropolishing, resulting in a smooth, polished surface that eliminates microscopic imperfections. This finish reduces friction during delivery, minimizes thrombus formation, and promotes rapid endothelialization. Consequently, blood vessel healing accelerates, supporting better integration with the vessel walls.

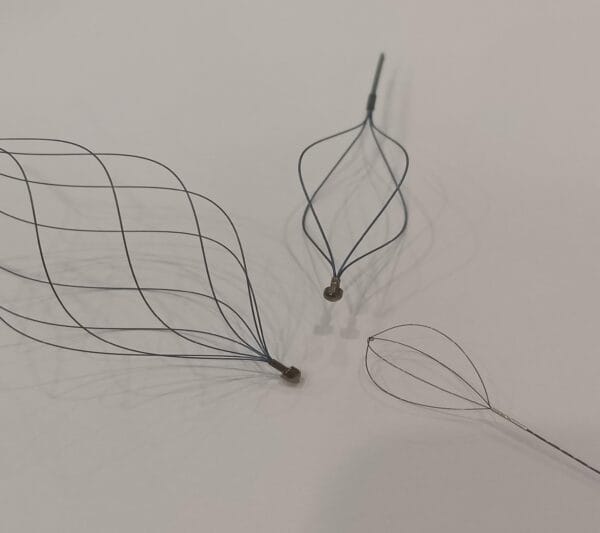

Wide Diameter Range for Customized Treatment

Designed to meet diverse clinical needs, our stent is available in diameters ranging from 5 mm to 40 mm. Whether treating narrow coronary arteries or larger peripheral vessels and aneurysms, customizable lengths and diameters ensure a precise fit tailored to individual patient anatomy.

Versatile Clinical Applications

The self expanding nitinol stent effectively treats peripheral artery disease (PAD), coronary and carotid artery stenosis, iliac artery occlusions, and supports aortic aneurysm repair. Additionally, it maintains bile duct patency in hepatobiliary interventions. Clinicians value its adaptability across elective and emergency vascular procedures.

Key Advantages of Our Self Expanding Nitinol Stent

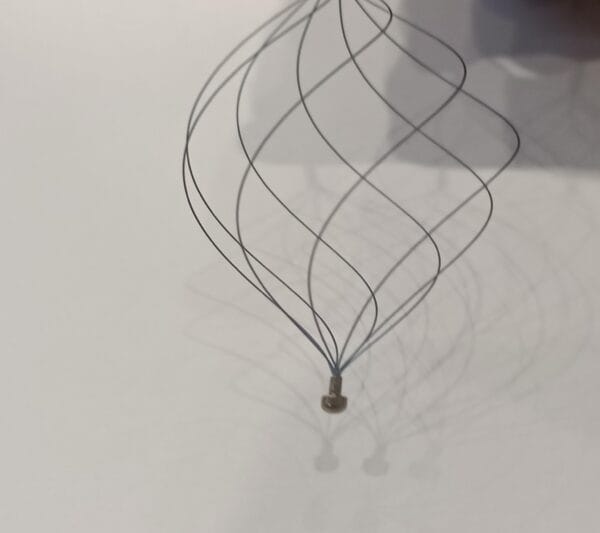

Reliable Radial Force and Vessel Support

Our stent continuously exerts outward radial force to keep vessels open, resisting recoil from calcified lesions. Its dynamic scaffolding accommodates pulsatile blood flow, preventing vessel collapse without risking overexpansion.

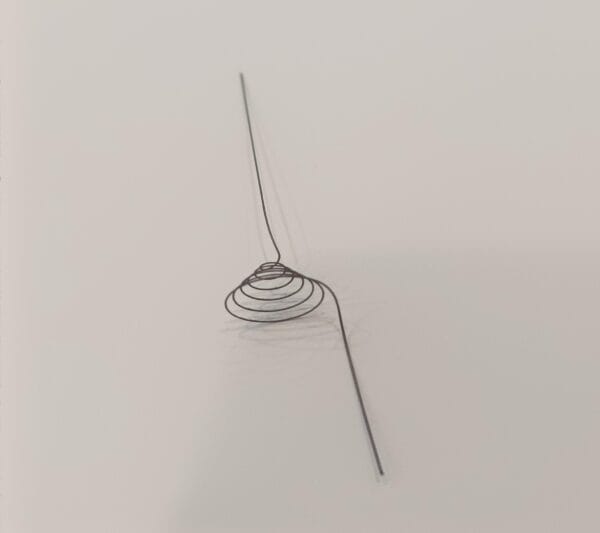

Minimal Trauma and Exceptional Flexibility

Featuring a low-profile design, the stent navigates tortuous vascular pathways smoothly, bending up to 180 degrees without kinking. Controlled expansion safeguards delicate tissues during deployment, reducing trauma and enhancing patient safety.

Long-Term Durability

Thanks to Nitinol’s exceptional fatigue resistance, the stent endures decades of cyclic stress from heartbeat and movement without fractures or migration. Patients benefit from lifelong vascular support with minimal need for repeat interventions.

MRI Compatibility and Ease of Use

Nitinol’s non-ferromagnetic properties allow safe MRI scans post-implantation. Pre-loaded delivery systems enable single-operator deployment, while radiopaque markers provide precise fluoroscopic visibility, simplifying procedures in busy cath labs.

Customizable Solutions and Quality Assurance

We offer tailored stent configurations—adjusting strut thickness, cell design, and taper ratios—to meet unique clinical demands. Every device undergoes stringent testing, including radial force validation and fatigue simulation, produced in an ISO 13485-certified facility ensuring global compliance.

Proven Clinical Success and Cost Efficiency

With over 500,000 implanted units globally, our stent demonstrates a 98% success rate in patient outcomes. Bulk pricing, extended shelf life, and reusable delivery systems reduce hospital costs and procedural expenses effectively.

Commitment to Sustainability

Our manufacturing recycles 99% of waste, uses water-based polishing to avoid harmful chemicals, and reduces carbon emissions by 40% compared to industry standards.

Conclusion

The self expanding nitinol stent integrates cutting-edge material science with thoughtful design to deliver superior vascular repair solutions. Backed by rigorous quality control and clinical validation, it’s a trusted choice in angioplasty, aneurysm management, and beyond—where precision engineering truly meets life-saving innovation.

▸ Expert Guidance: 24/7 support via nitinolalloy.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.