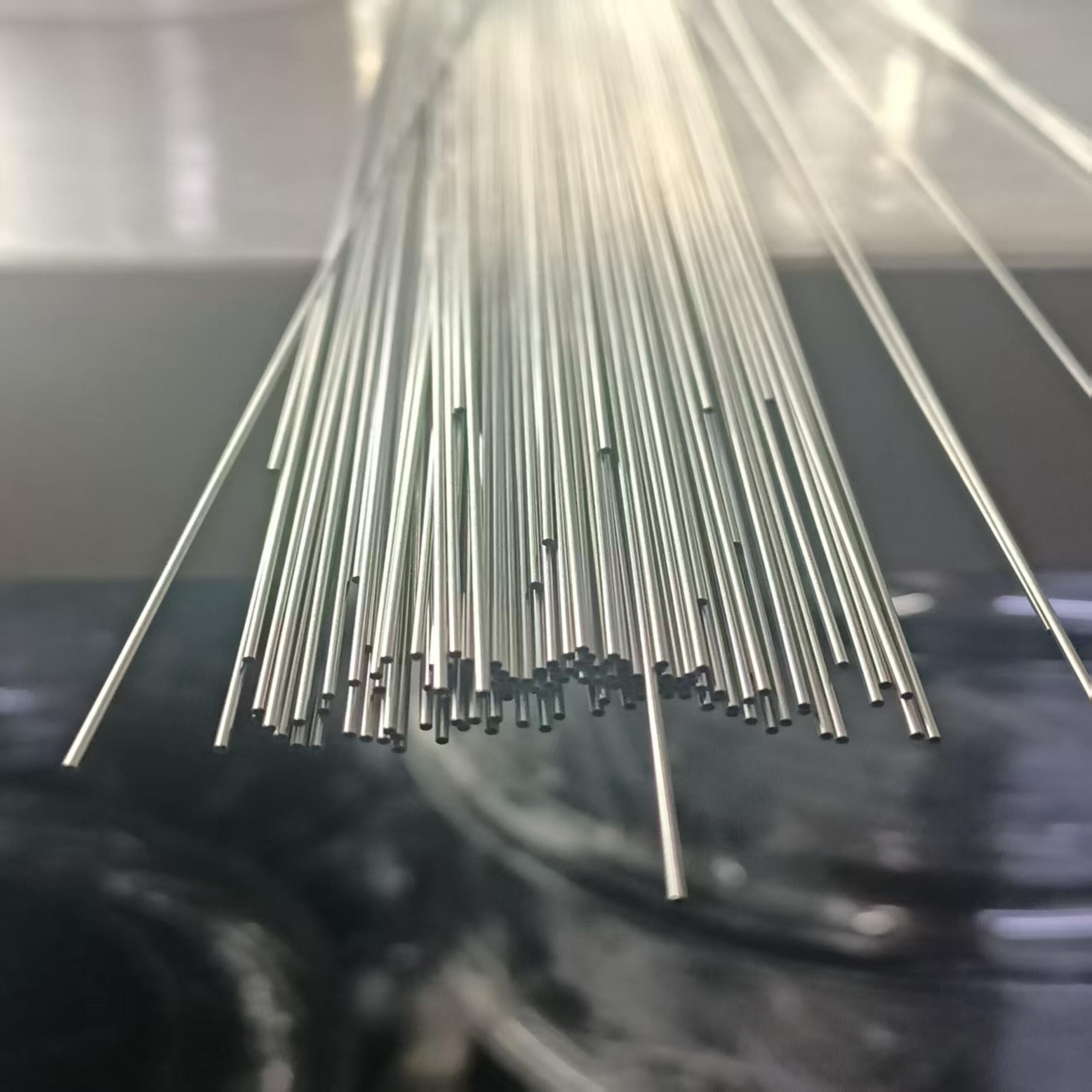

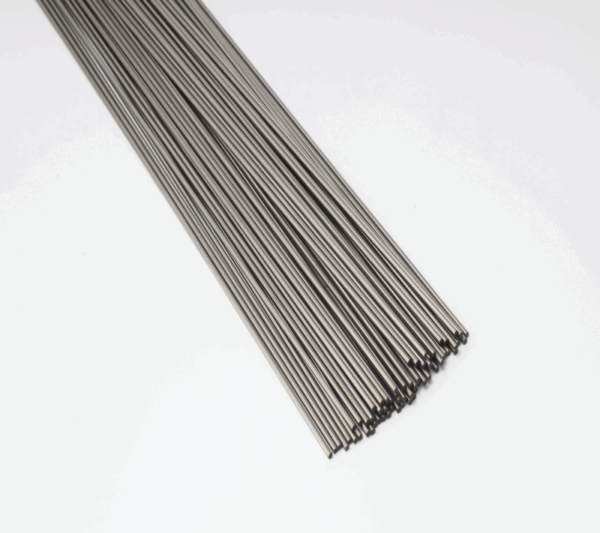

Nitinol Superelastic Tube: Premium Semi-Finished Medical Catheter Material

Material Overview

Our nitinol superelastic tube is expertly crafted from high-grade nickel-titanium alloy, combining exceptional superelasticity with shape memory capabilities. This advanced alloy effortlessly withstands extreme stress and reliably returns to its original form, making it perfect for demanding medical applications. With outstanding biocompatibility, our tubes meet stringent requirements for safe, implantable medical devices. We source only premium raw materials to guarantee consistent performance across critical uses.

Surface Finish Options

Select from multiple surface finish options customized to suit your specific application requirements.Our standard finishes include:

Electropolished: Creates a smooth, friction-reducing surface with excellent protection against corrosion.

Mechanically Polished: Ensures a uniform texture for precise handling and assembly.

As-Drawn: Retains the natural tube surface, ideal for further customized processing.

Each finish is designed to optimize performance whether in medical instruments or industrial settings.

Diameter Range and Precision

Our nitinol superelastic tubes are available in diameters ranging from 0.1 mm to 5.0 mm, accommodating a wide spectrum of uses. From ultra-thin tubes used in minimally invasive surgical tools to thicker tubes for structural components, we deliver tight dimensional tolerances essential for reliability in catheters, stents, and guidewires. Custom sizes and specifications can be provided upon request.

Applications

This semi-finished tube serves as a vital component in both medical and industrial innovations:

Medical Uses: Flexible, kink-resistant catheters; durable stent frameworks; steerable guidewires; and robust endoscopic tool parts.

Industrial Uses: Aerospace actuators, precision robotics sensors, and advanced consumer electronics components.

Why Choose Our Nitinol Superelastic Tube?

Precision Manufacturing: Cutting-edge cold drawing and laser cutting ensure unmatched dimensional consistency.

Customizable Solutions: Adjust alloy composition, surface finish, and mechanical properties such as transformation temperature (Af) to suit your design.

Comprehensive Quality Control: Tested under ISO 13485 certification, including assessments of tensile strength, fatigue performance, biocompatibility, and ASTM F2129 corrosion resistance.

Medical-Grade Safety: Compliant with USP Class VI and ISO 10993 for implantable materials, with full traceability and no harmful additives.

Fast Turnaround: Prototypes ready in 2 weeks, bulk production in 4–6 weeks thanks to automated, local sourcing.

Expert Support: Guidance on material selection, prototyping, regulatory compliance, laser cutting, and shape-setting.

Cost Efficiency: Semi-finished tubes reduce machining time and material waste, offering competitive pricing at scale.

Global Compliance: Meets EU MDR, FDA, and RoHS standards with complete certification and test documentation.

Elevate Your Medical Device Design with Nitinol Superelastic Tubes

Our nitinol superelastic tube perfectly balances innovation, durability, and biocompatibility to overcome the toughest medical engineering challenges. Partner with us for dependable, high-performance materials that enhance your catheter, stent, or implantable device designs. Contact our sales team today for samples, quotes, or technical consultations.

▸ Facebook account:Facebook

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolusa.com

Mid East Region:getnitinol.com

Reviews

There are no reviews yet.