Nitinol-Based Medical Implants: Engineered Superelasticity for Next-Generation Healthcare

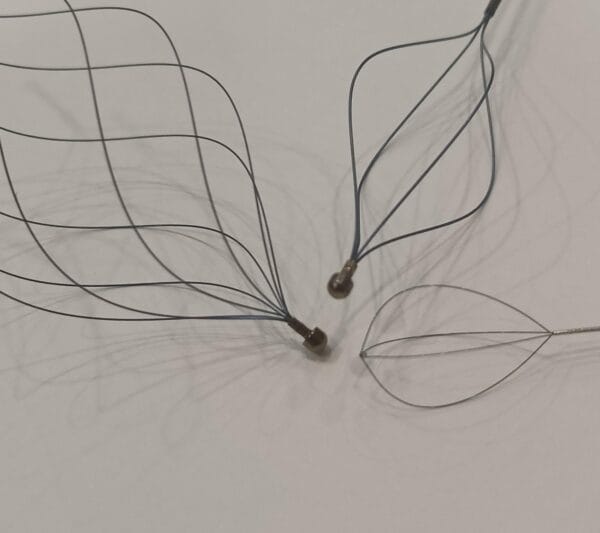

Superior Material: Nitinol Alloy for Medical Implants

These devices utilize a nickel-titanium composite recognized for its exceptional elasticity and shape retention properties.

The alloy demonstrates reversible deformation recovery, maintaining structural integrity through repeated flexion cycles in clinical environments.

Its biocompatibility ensures safe interaction with human tissues, significantly reducing the risk of rejection. Trusted by doctors and engineers alike, Nitinol offers the durability and flexibility needed for the most demanding medical environments.

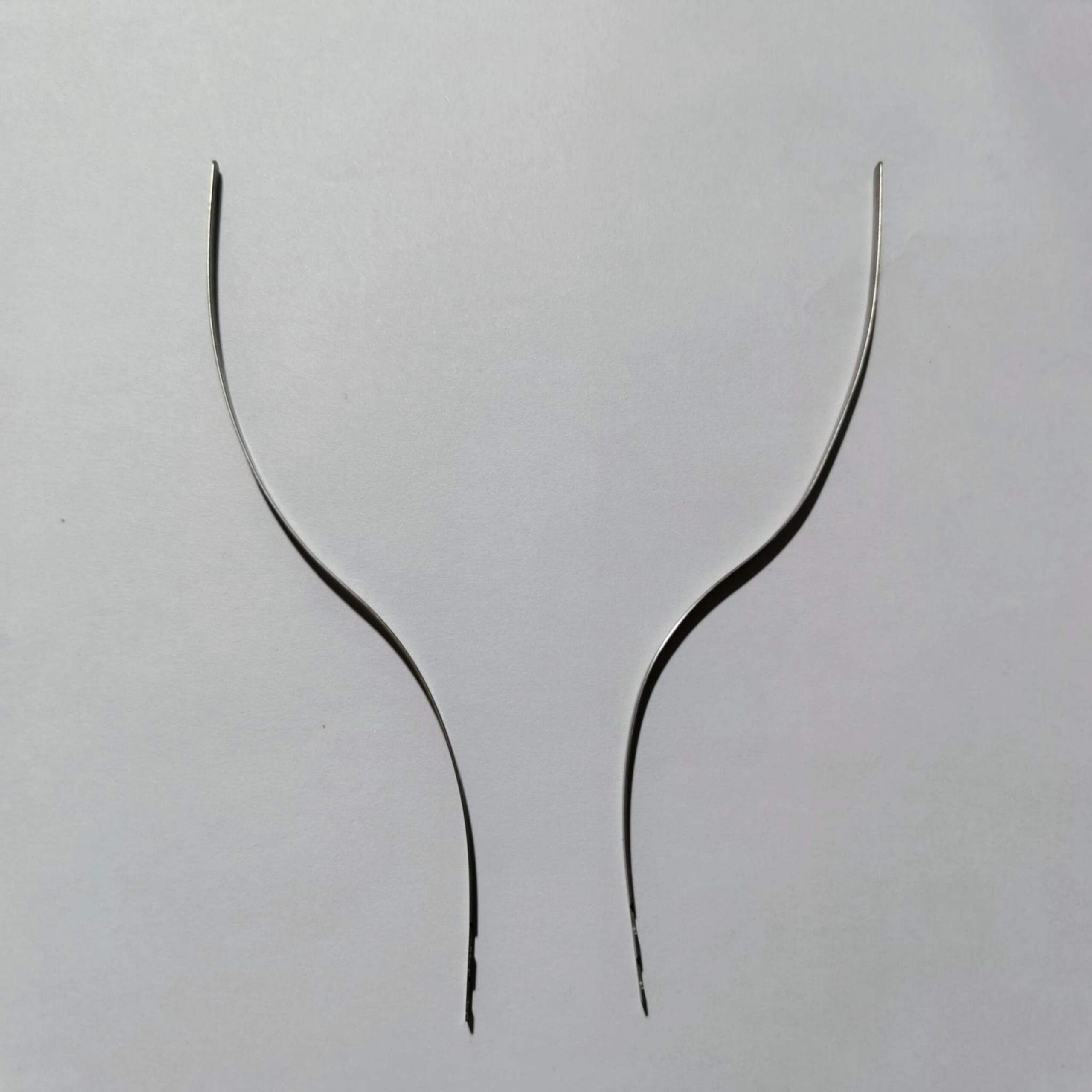

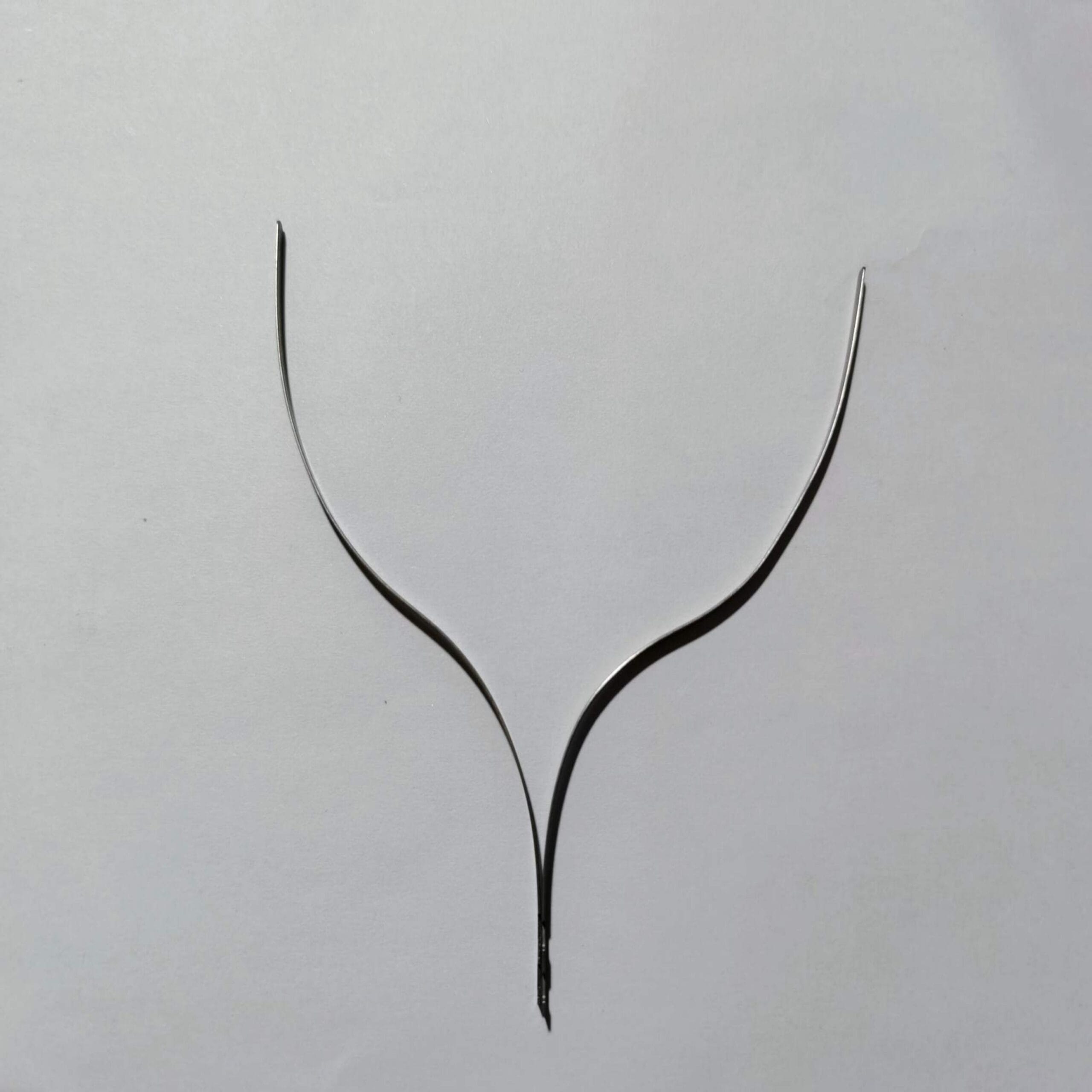

Advanced Surface Finish for Safety and Performance

Each Nitinol implant undergoes a meticulous surface treatment process to ensure optimal performance and safety. We apply a meticulous polishing process to ensure a sleek, uniform surface—removing any sharp contours that might irritate surrounding tissue.For specialized applications, we offer electropolishing or acid etching to enhance corrosion resistance. The result is a long-lasting implant that functions reliably inside the body for years.

Wide Diameter Range for Custom Medical Solutions

Precision surface engineering achieves <0.5μm roughness (Ra) through advanced finishing protocols, minimizing tissue interaction risks.

0.1–1.0 mm: Precision tools for minimally invasive surgeries

1.0–3.0 mm: Cardiovascular stents and guidewires

3.0–10.0 mm: Orthopedic staples and dental archwires

Custom sizing ensures a perfect anatomical fit, supporting personalized treatment plans.

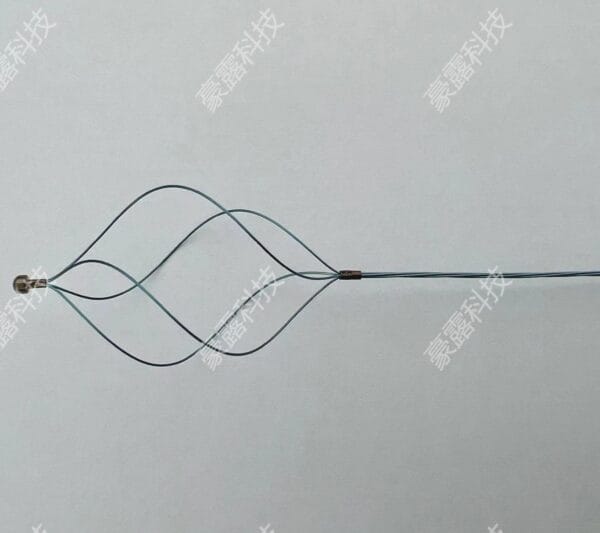

Core Medical Uses of Nitinol Implants in Contemporary Healthcare

Cardiovascular Care

Nitinol implants are revolutionizing heart treatments. Superelastic stents restore blood flow by expanding blocked vessels without losing shape, while guidewires maneuver seamlessly through intricate vascular networks.

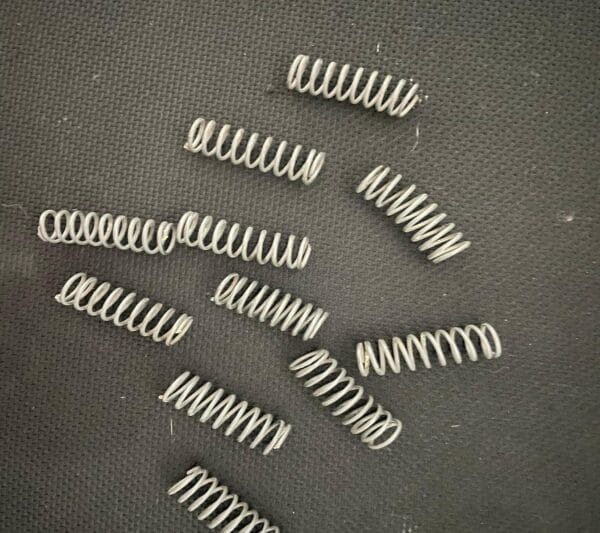

Orthopedic Solutions

Surgeons rely on Nitinol for bone fracture fixation. Responsive to thermal changes, Nitinol staples and plates deliver controlled compression, aiding reliable fracture alignment and healing.

Dental Innovations

Nitinol archwires used in orthodontics provide continuous force, leading to faster tooth alignment with reduced patient discomfort.

Neurology and Beyond

Nitinol is essential in neurovascular coils for aneurysm treatment and supports catheters and sensors in intricate brain procedures thanks to its flexibility and adaptability.

Why Choose Our Nitinol Implants?

✅ Unmatched Superelasticity

Our Nitinol implants tolerate extreme bending and twisting. They endure millions of stress cycles without failure—ideal for dynamic environments inside the human body.

✅ Precision Manufacturing

Using laser cutting and advanced heat treatment, we maintain tight tolerances (±0.01 mm) to ensure every product meets exact specifications.

✅ Fast Turnaround, Global Reach

We ship standard Nitinol implants within 7–10 days. Custom orders are completed in just 3–4 weeks. Our robust logistics network serves hospitals and clinics worldwide.

✅ Rigorous Quality Standards

All implants undergo mechanical testing, chemical analysis, and biocompatibility assessments. Our manufacturing processes align with ISO 13485 and ASTM F2063 quality standards, ensuring global regulatory compliance.

✅ Expert Support Team

Our expert team—comprising engineers and clinical consultants—offers personalized support in selecting and implementing the right implant solutions.We provide technical drawings, material certificates, and surgical guides for seamless integration.

Trusted by Leading Medical Brands

Over 500 hospitals and clinics worldwide rely on our Nitinol implants for life-saving procedures. Partner with us and experience the perfect blend of innovation, reliability, and clinical success.

Request Samples or Specifications Today

Experience the difference for yourself—risk-free. Contact us today to request sample kits, CAD files, or bulk pricing.

Elevate patient care with the gold standard in superelastic medical alloys: Nitinol.

Prototyping Support

Expert Guidance: 24/7 support via

Facebook account:Facebook

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolalloy.com

Mid East Region:getnitinol.com

Also Available in Our Nitinol Product Family:

| Product | Description |

|---|---|

| Nitinol Wire | High-performance shape memory wire |

| Nitinol Tube | Ultra-thin precision tubing |

| Nitinol Rope | Flexible and durable for complex movement |

| Nitinol Guide Wire | Steerable wire for precise medical navigation |

Reviews

There are no reviews yet.