Nitinol Stent Laser Cutting Technology: Tailored Performance and Accuracy

Why Choose Nitinol for Medical Stents?

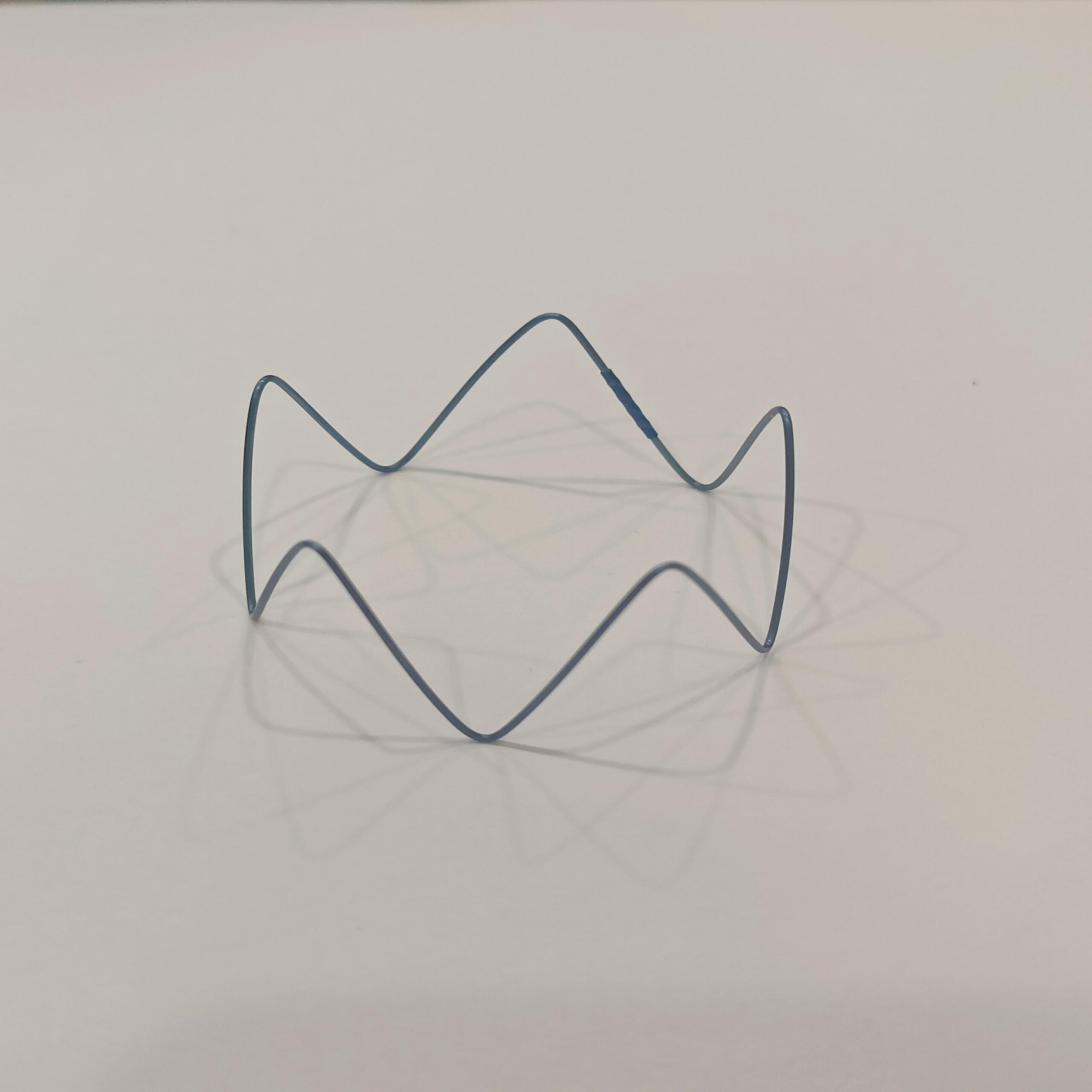

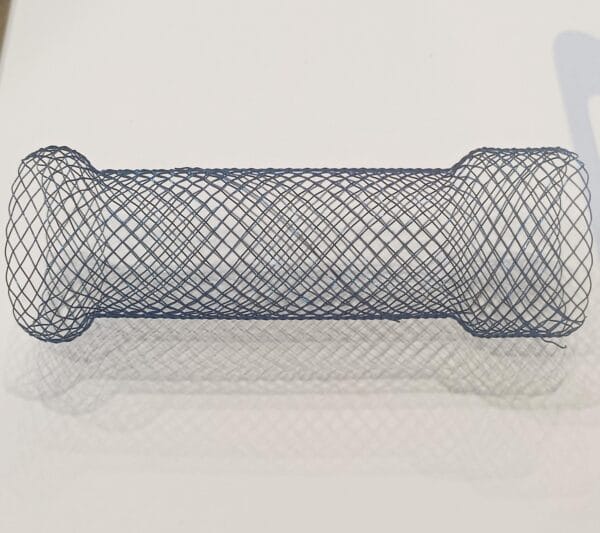

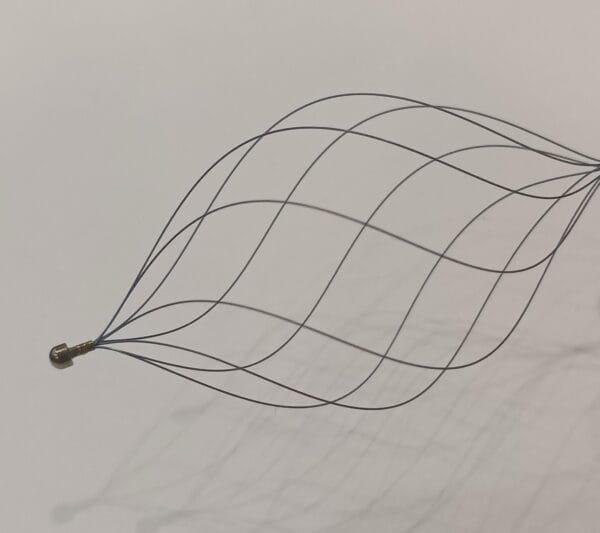

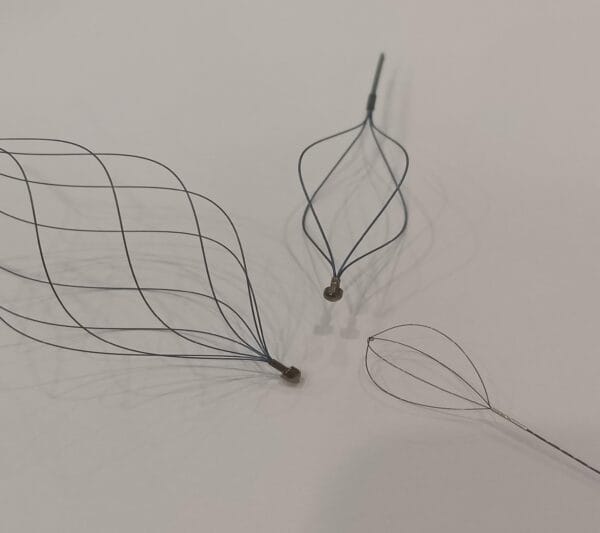

We choose high-performance Ni Ti alloy for all our medical stents.Nitinol’s unique composition provides shape memory and superelastic capabilities, letting the stent expand or contract when exposed to body heat. This temperature-responsive behavior allows the device to conform seamlessly to anatomical structures, delivering a secure fit and patient comfort without sacrificing support strength. The material’s adaptability minimizes mechanical stress on surrounding tissues, promoting long-term stability. Precision laser cutting further refines these benefits, ensuring clean edges and uniform patterns for reliable performance in dynamic bodily environments.

Moreover, its flexibility reduces the risk of vessel damage and enhances patient outcomes. Whether placed in arteries, airways, or ducts, nitinol provides long-term, adaptive performance.

Superior Surface Finish for Safer Use

To ensure patient safety, every stent undergoes advanced surface finishing. This polishing process eliminates micro-defects, which not only minimizes insertion friction but also significantly reduces clotting risks. Consequently, our nitinol stent laser cutting products meet the highest medical standards for biocompatibility, making them safe for prolonged use within the human body.

Custom Diameters to Fit All Needs

Our laser-cut nitinol stents are available in diameters ranging from 1 mm to 10 mm. Smaller sizes are suitable for delicate procedures such as coronary interventions, while larger sizes are ideal for tracheal or biliary applications. Even better, we offer custom sizing options to fit unique anatomical or surgical requirements—just share your specs, and we’ll manufacture accordingly.

Applications Across Multiple Medical Fields

Our advanced nitinol stent laser cutting process is engineered to meet the demands of multiple medical disciplines.

Cardiovascular: Relieve artery obstructions to support healthy heart function.

Peripheral Vascular: Treat narrowed vessels in limbs and organs.

Neurology: Improve brain blood flow to help prevent strokes.

Respiratory: Keep airways open in tracheal or bronchial conditions.

Urology: Relieve obstructions in the urinary system or prostate.

Laser Cutting Technology That Sets Us Apart

Our stents are manufactured using precision laser cutting, which ensures sharp, clean edges and consistent mesh designs. This advanced method allows intricate patterns without compromising strength or flexibility. Additionally, this process keeps the stents lightweight yet highly durable, a key factor in long-term implantation success.

Key Benefits of Our Nitinol Stents

Durable and Flexible: Withstand motion in active areas like joints or the heart.

Fast Turnaround: Efficient production to meet urgent clinical needs.

Custom Solutions: Adjust diameter, mesh density, and length as required.

Rigorous Quality Control: Compliant with ISO 13485 and international standards.

Expert Support: Get assistance from design to post-surgical application.

Competitive Pricing: Premium quality at accessible rates.

Global Certification: FDA, CE, and other regulatory approvals provided.

From Concept to Certification—We Deliver

We don’t just manufacture; we partner with you. From your initial design through to regulatory documentation, we ensure your nitinol stent laser cutting project succeeds in every detail. With extensive engineering support and global logistics capabilities, we simplify your path from prototype to production.

▸ Expert Guidance: 24/7 support via nitinolalloy.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.