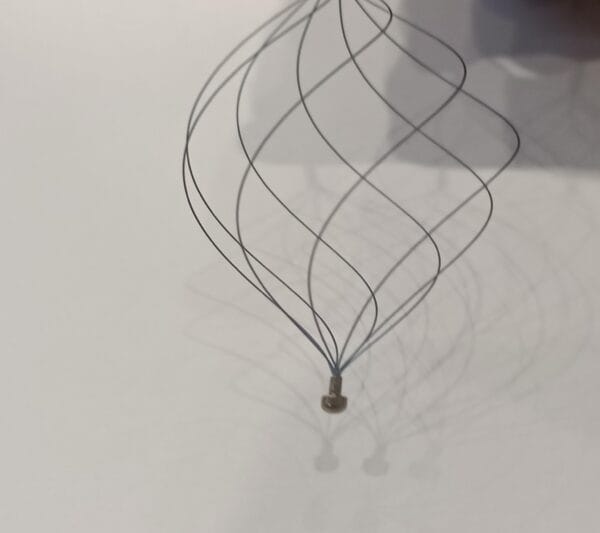

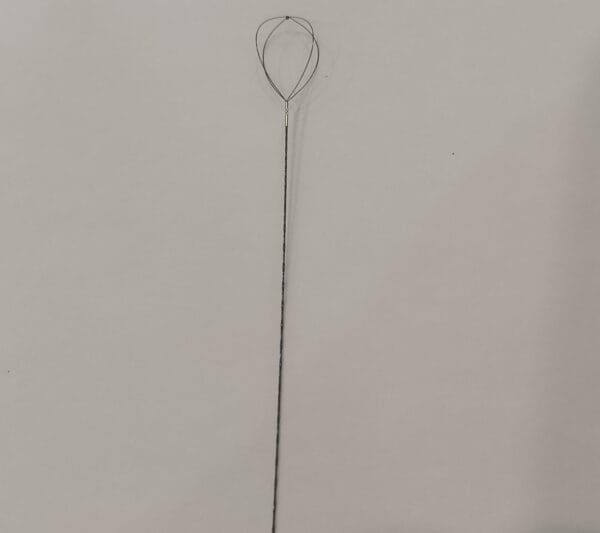

Nitinol Shape-Setting Custom Medical Components

Material: High-Performance Nitinol for Precision Shape Setting

We manufacture our medical components using premium-grade Nitinol (Nickel-Titanium alloy), renowned for its superelasticity and shape memory properties. Thanks to its ability to return to a pre-set shape when exposed to temperature changes, Nitinol is ideal for medical devices that must perform reliably in dynamic, high-stress environments. We only use medical-grade Nitinol, ensuring superior biocompatibility, corrosion resistance, and long-term durability.

Surface Finish: Smooth, Clean, and Biocompatible

We provide multiple surface finishing options to meet stringent medical industry requirements. Choose from electropolished, mechanically polished, or etched finishes, each tested thoroughly for cleanliness and safety.

Electropolishing reduces surface friction—ideal for implants and delicate instruments.

Mechanical polishing ensures a uniform texture for consistent tissue contact.

All finishes undergo rigorous inspection to eliminate contaminants and support safe human use.

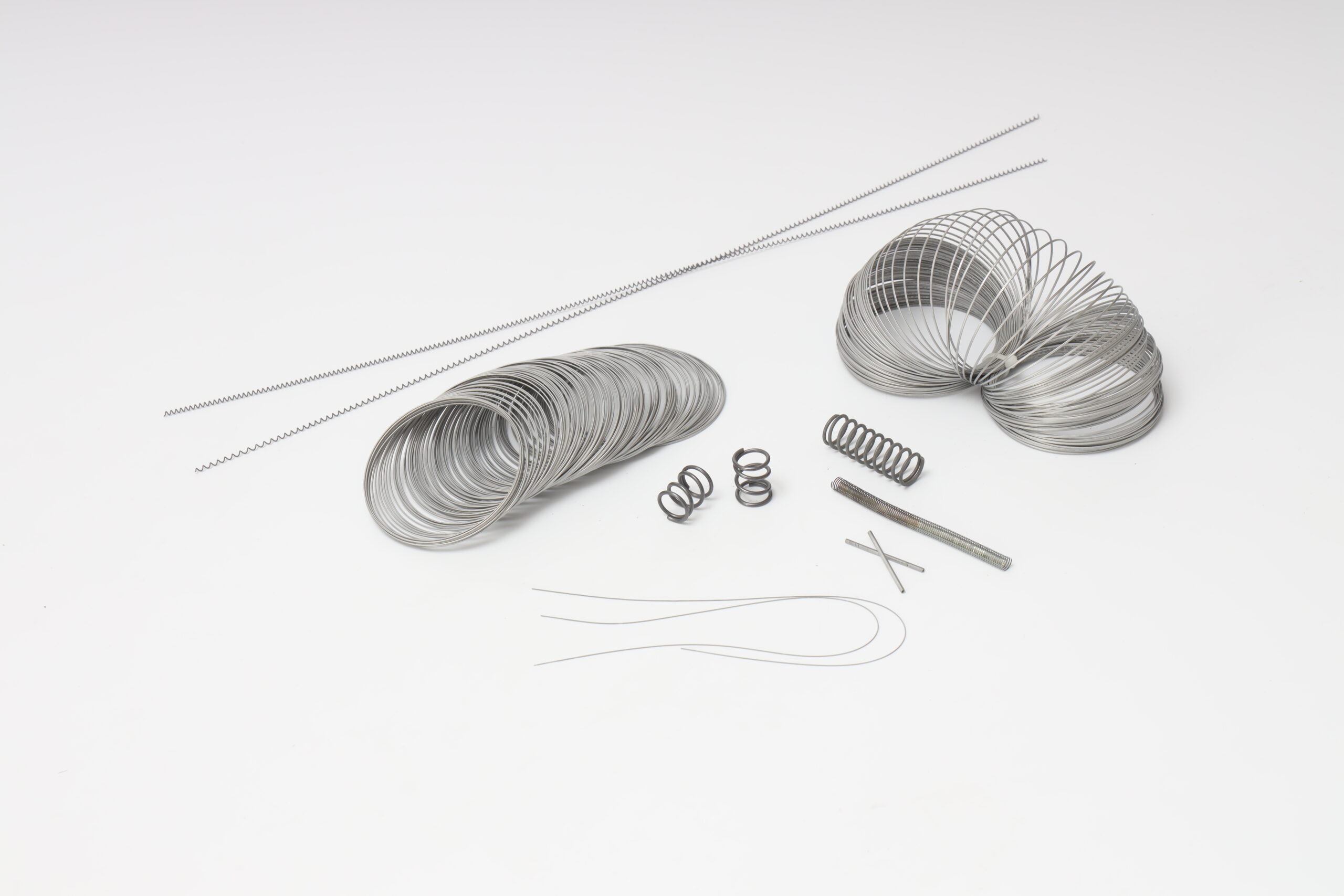

Diameter Range: Versatile Sizing for Every Medical Need

Our Nitinol shape-setting components are available in diameters ranging from 0.1 mm to 10 mm, supporting a broad range of medical devices—from ultra-fine wires for minimally invasive procedures to thicker rods used in structural implants. We use precision laser cutting and controlled heat treatment to ensure dimensional accuracy at every scale. Custom sizing is also available for specialized applications.

Applications: Advanced Solutions for Modern Medicine

Nitinol shape-setting technology plays a critical role in cutting-edge medical solutions:

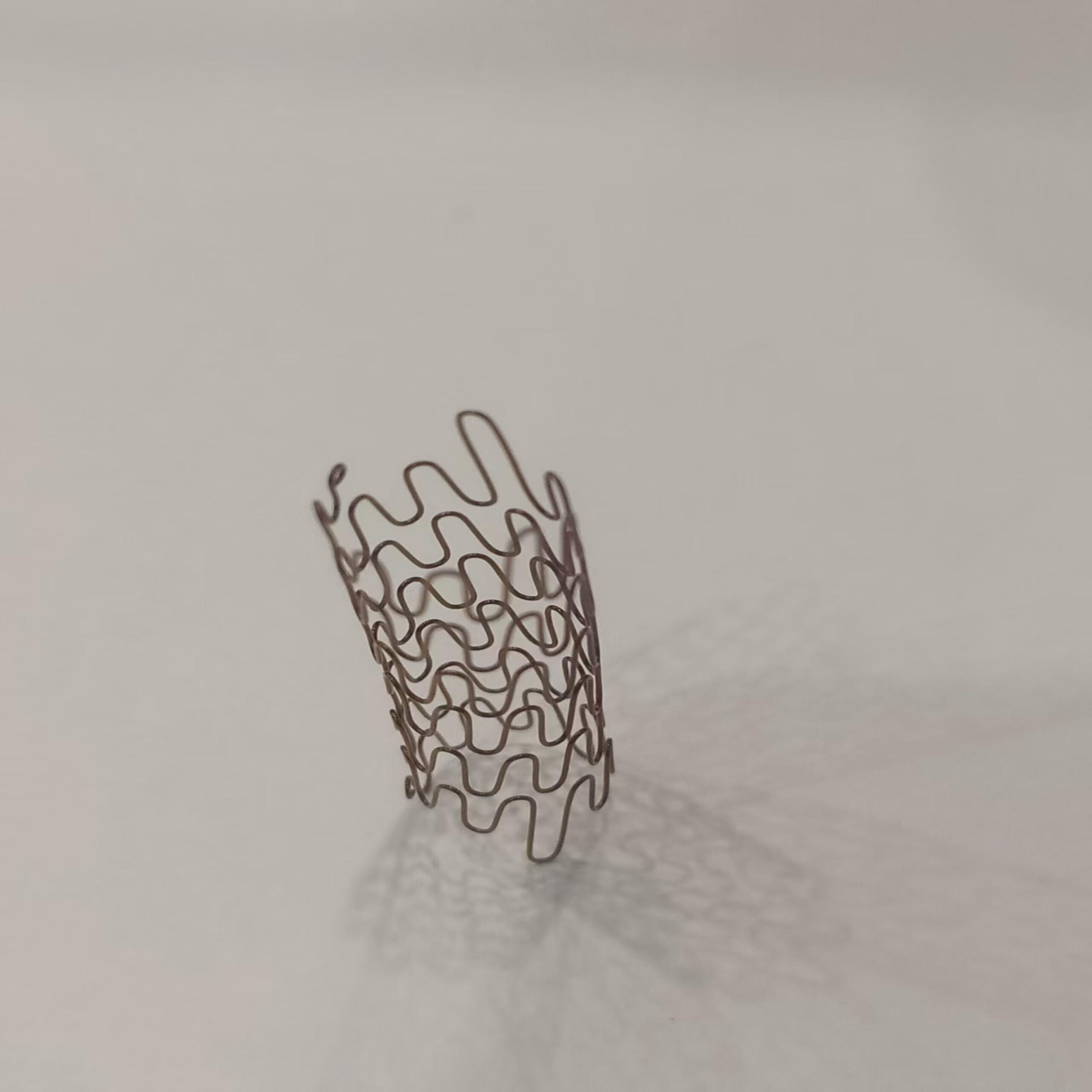

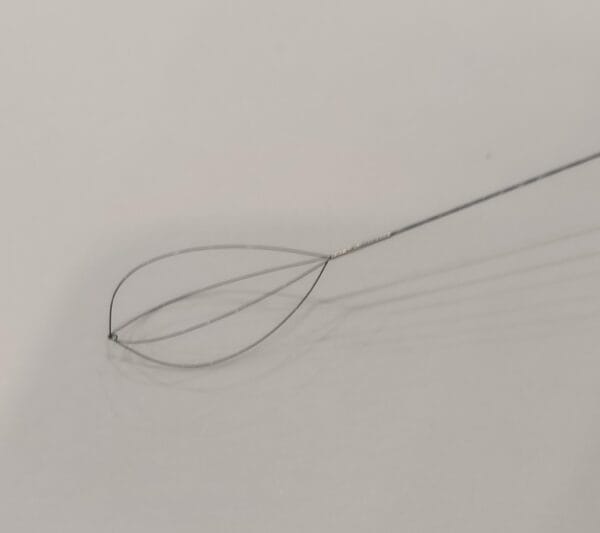

Cardiovascular Devices: Stents, guidewires, and occlusion systems that rely on flexibility and post-deployment shape retention.

Orthopedic Implants: Bone staples, spinal rods, and fixation tools designed for high fatigue resistance and mechanical strength.

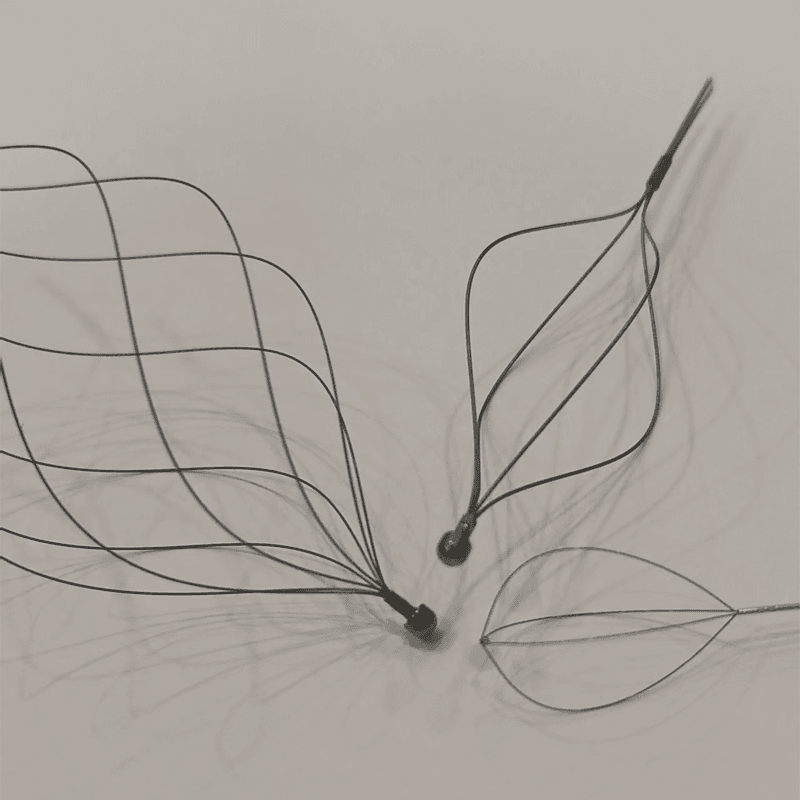

Surgical Instruments: Endoscopic tools, biopsy forceps, and retrieval baskets benefit from Nitinol’s lightweight, non-magnetic characteristics.

Dental & Orthodontics: Archwires and braces that gently and consistently apply pressure using Nitinol’s shape memory effect.

Why Choose Our Nitinol Shape-Setting Medical Components?

Expertise in Nitinol Processing

With over 15 years of experience, our team leads the industry in advanced Nitinol shape-setting. We apply precise heat treatment and laser machining techniques to create complex, stable geometries tailored to critical medical needs.

Customization Without Compromise

We customize components to your exact requirements—adjusting parameters like transition temperature, radial force, and geometry curvature. Our rapid prototyping services help you validate and optimize your design before scaling up to full production.

Strict Quality Control

Every Nitinol component undergoes 100% inspection for dimensional accuracy, surface integrity, and mechanical properties. We comply with ISO 13485 and provide full traceability. Biocompatibility is verified through ISO 10993 testing to ensure patient safety.

Fast Turnaround, Global Support

We deliver prototypes in 2 weeks and bulk orders in 6–8 weeks. Our global logistics ensure timely delivery anywhere in the world. Our dedicated engineering team supports your project from concept to completion, optimizing design and reducing costs.

Competitive Pricing for High-Volume Orders

Our automated production and efficient material usage enable competitive pricing without sacrificing quality. We offer bulk discounts to meet both performance and budget goals.

Enhance Your Medical Devices with Nitinol Innovation

Our Nitinol shape-setting medical components enhance device performance, improve patient outcomes, and support minimally invasive techniques. Whether you’re developing new products or upgrading existing ones, we deliver the precision, reliability, and biocompatibility modern medicine demands.

Contact Us Today

Submit your specifications for a free quote. Let’s work together to engineer Nitinol components that exceed expectations in performance, safety, and longevity.

Reviews

There are no reviews yet.