Smart Engineering with Nitinol Shape Memory Alloy: Precision Components for Advanced Applications

Unlock the remarkable potential of Nitinol Shape Memory Alloy (SMA) — a material that “remembers” its shape and adapts to mechanical stress with extraordinary resilience. As a trusted manufacturer, we specialize in producing high-performance Nitinol components that deliver reliability, flexibility, and unmatched functionality across demanding industries.

Engineered Materials: Pure, Precise, Powerful

Our process begins with premium raw materials — high-purity Nickel and Titanium. Precise atomic ratios are strictly controlled to ensure the Shape Memory Effect (SME) and Superelasticity (SE) function reliably. Advanced vacuum induction melting guarantees material homogeneity and consistent austenite finish temperatures (Af). Each batch undergoes rigorous chemical analysis, giving you certified, high-quality Nitinol every time.

Surface Finishes: Optimized for Performance

Our surface finishing options are customized to match your specific application needs.

Bright Polished: Smooth, reflective surface ideal for medical and micro-mechanical devices

Etched: Textured finish for enhanced bonding or controlled friction

Oxidized: Durable dark coating for thermal resistance and visual contrast

Every finish is burr-free and dimensionally uniform, reducing your post-processing needs and ensuring consistent quality.

Versatile Diameters: From Micro Wires to Macro Rods

Our diameter range covers a wide spectrum:

Standard Nitinol Wire & Rod: 0.1 mm–10 mm (0.004–0.394 in), used in actuators, orthodontics, sensors, and couplings

Large-Diameter Nitinol Rods: Up to 25 mm (1.0 in), suited for industrial actuators and structural uses

- Precision Micro Wires: Available in ultra-fine sizes down to 0.05 mm (0.002 in), tailored for high-precision applications in electronics and minimally invasive procedures.

We apply high-precision drawing and grinding methods to deliver consistent dimensions and stable mechanical behavior.

Applications: Where Nitinol Shape Memory Alloy Excels

Nitinol SMA solves engineering challenges across industries:

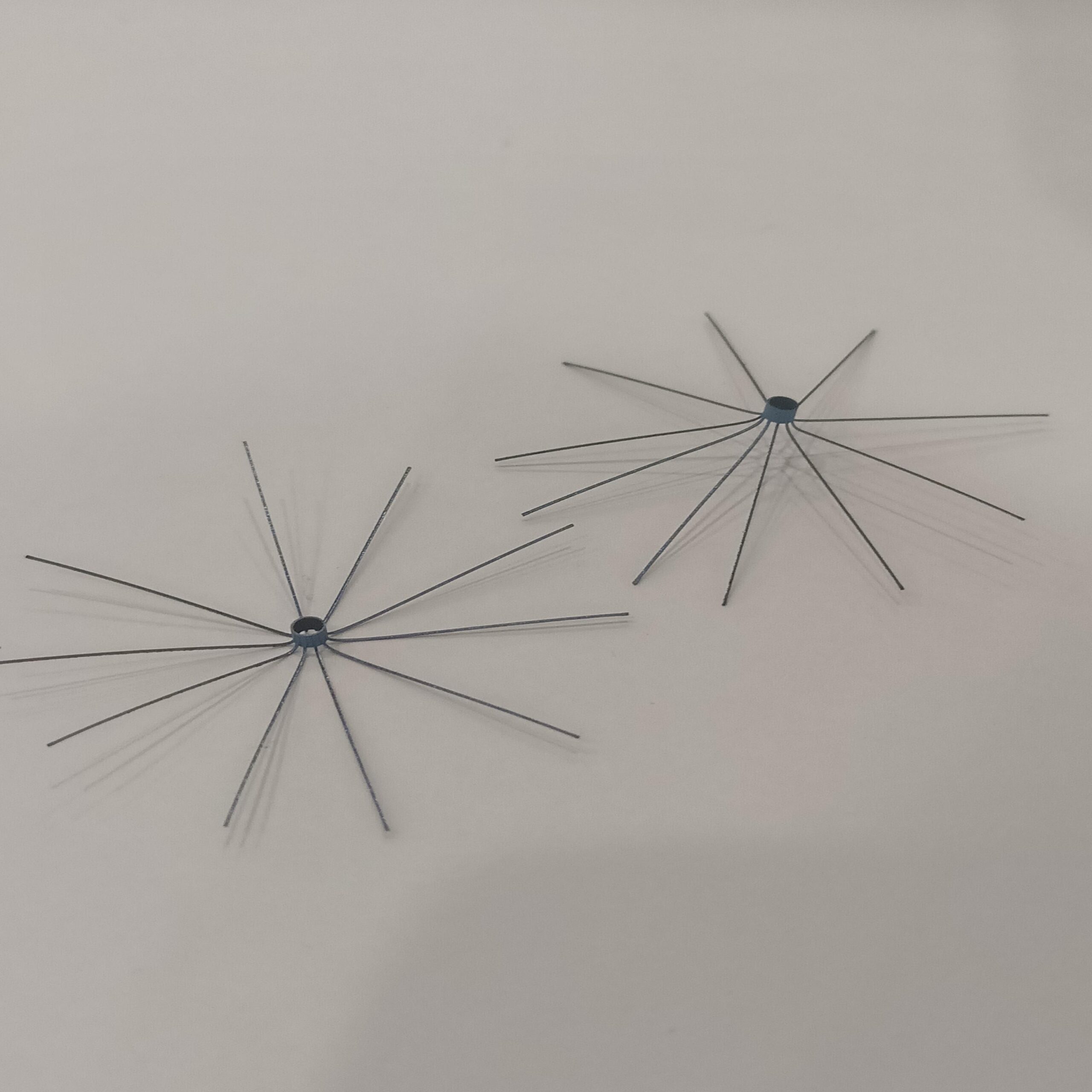

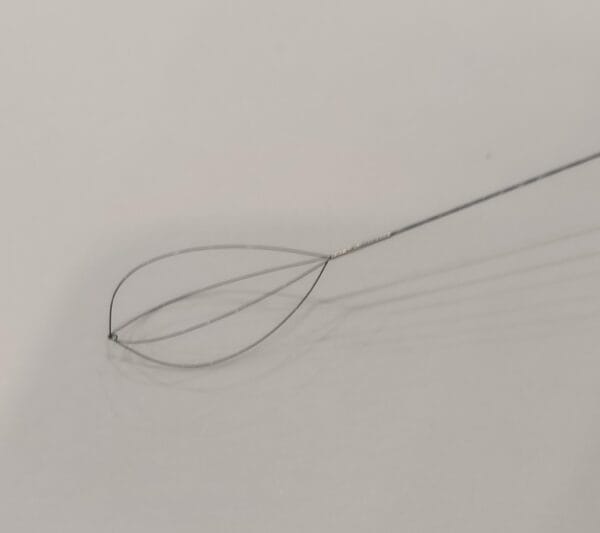

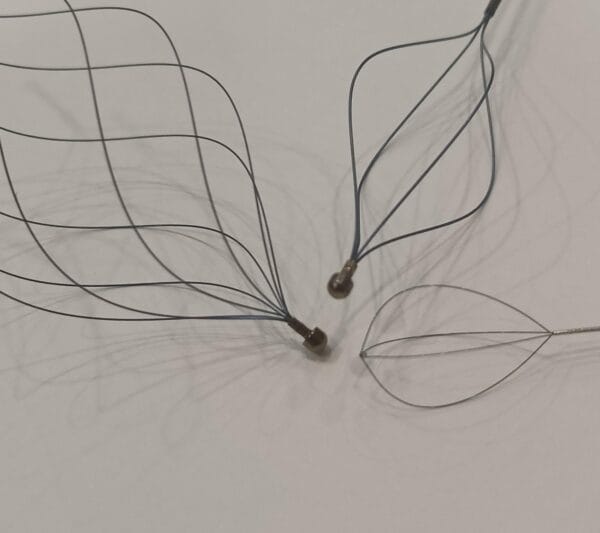

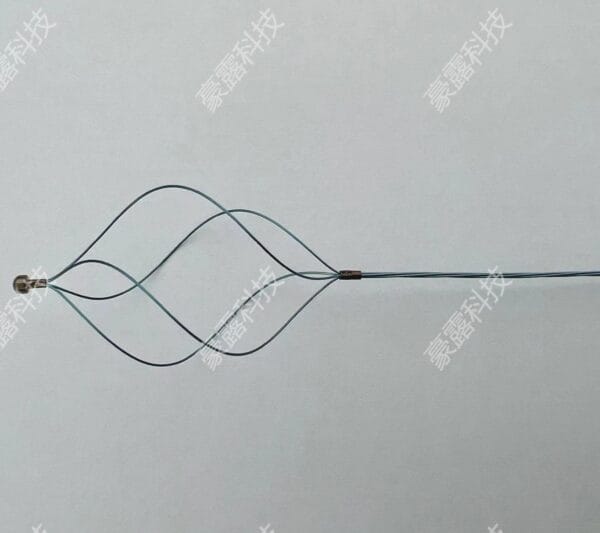

Medical Devices: Stents, orthodontic wires, biopsy tools, surgical guides — offering superelasticity and proven biocompatibility

Industrial Uses: Actuators, dampers, fluid valves, connectors — resilient in motion and extreme environments

Aerospace & Defense: Deployable systems, vibration isolation, silent actuators — lightweight yet durable

Consumer Goods: Eyewear frames, smartphone haptics, coffee valves — smart features in everyday products

Emerging Technologies: MEMS, soft robotics, energy harvesting — powering the future of innovation

Why Choose Our Nitinol Shape Memory Alloy?

Reliable Smart Functionality:Delivers consistent SME and SE characteristics, engineered to withstand repeated stress without degradation.

Strict Quality Control: Mechanical testing, DSC analysis, and surface inspections with certificates included

Manufacturing Expertise: Full mastery of Nitinol melting, forming, and heat treatment

Reliable Delivery: Streamlined supply chain with secured raw material inventory

Application-Driven Support: Design consultation and integration guidance based on real-world performance

Customization Options: Tailored diameters, unique forms (tubes, sheets), and custom Af settings available

Standards Compliant: ASTM F2063, ISO 5832-11, and more

Experience the Smart Advantage

Our advanced Nitinol Shape Memory Alloy solutions offer intelligent motion, exceptional durability, and consistent results.

▸ Expert Guidance: 24/7 support via nitinolalloy.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.