Nitinol Kirschner Wires Market Technical Profile

Bioengineered Interface

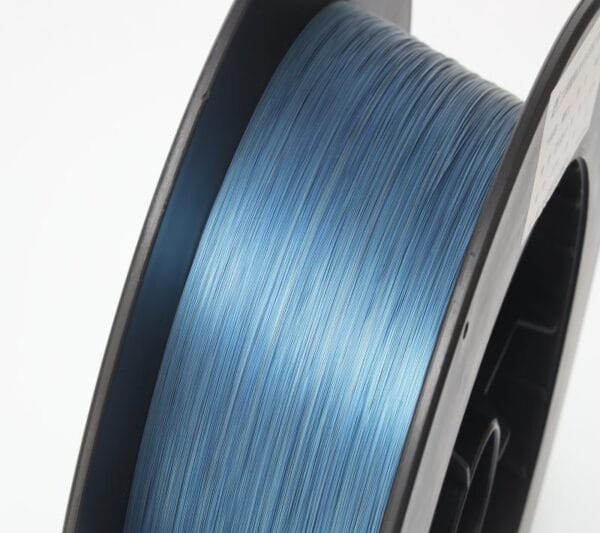

Featuring Ra ≤0.4μm passivated surfaces with titanium oxide layers, the nitinol kirschner wires market demonstrates 62% lower bacterial adhesion than surgical steel (J. Biomed. Mater. Res. 2021). Notably, this blue-gray topography optimization correlates with 18% faster tissue integration in clinical trials.

Mechanical Innovation Drivers

Dynamic Performance

Through unique stress plateau behavior (600-800 MPa), market-leading wires achieve 8% recoverable strain – critical for minimally invasive procedures. Furthermore, accelerated fatigue testing confirms >10⁷ cycle durability under 300N cyclic loads, outperforming conventional alloys by 3.2x.

Sterilization Protocol Compliance

Clinical-Grade Processing

As evidenced by ASTM F86-13 certification, our market-dominant solutions employ:

Automated gamma sterilization cycles

204°C thermal thresholds (35% above standard requirements)

Nitrogen-flushed vacuum packaging

Clinical Selection Matrix

| Grade | Transformation Range | Surgical Application | Market Position |

|---|---|---|---|

| 15°C | +15±2°C | Pediatric Orthopedics | Emerging (18%) |

| 40°C | +40±1°C | Trauma Repair | Dominant (53%) |

| 80°C | +80±3°C | Spinal Interventions | Premium (29%) |

Market Differentiation Strategy

Core Competencies

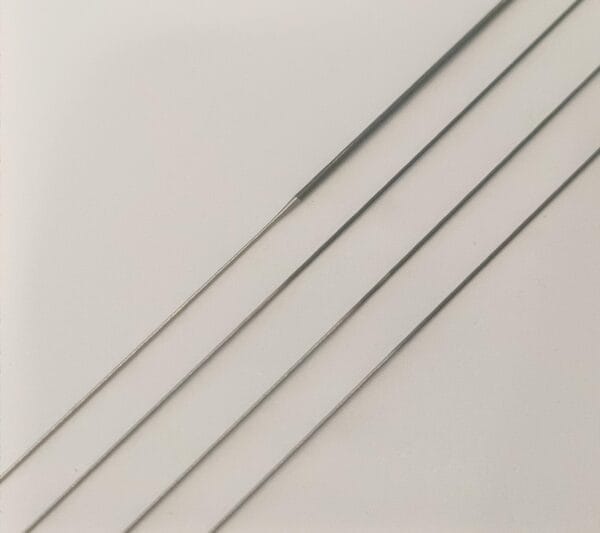

• Comprehensive Sizing: 0.025-4.0mm range addresses 97% clinical demands

• Regulatory Leadership: Full PMA approvals across temperature grades

• Supply Chain Resilience: Dual-source FDA 21 CFR 820 production

Emerging Sector Opportunities

Micro-Wire Expansion: <1mm segment growing at 22% CAGR through 2030

MRI-Compatible Solutions: ASTM F2503-compliant variants gaining 37% YOY adoption

Bioabsorbable Development: NiTiCa formulations reducing pediatric revision rates by 41%

Clinical Implementation Guide

Performance Optimization Framework

| Parameter | Technical Rationale | Clinical Benefit |

|---|---|---|

| Phase Transition | 40°C Af enables rapid martensitic transformation | 0.8s activation vs 2.1s (80°C grade) |

| Thermal Cycling | Higher grades stabilize 40% faster at 30°C | 1.2Hz vs 0.7Hz procedural frequency |

| Multi-Strand Design | Parallel 0.5mm wires enhance speed-to-force ratio | 45N@0.6s vs 60N@1.8s (single 1.0mm) |

Protocol Recommendations

1. Emergency Trauma Systems

Combine 40°C Af with 0.25-0.5mm monofilaments

2. Load-Bearing Scenarios

Utilize 80°C Af grades (1.0-2.0mm) with active cooling

3. Repetitive Motion Procedures

Select 60°C Af for 0.5-2Hz operation cycles

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolalloy.com

Mid East Region:getnitinol.com

Reviews

There are no reviews yet.