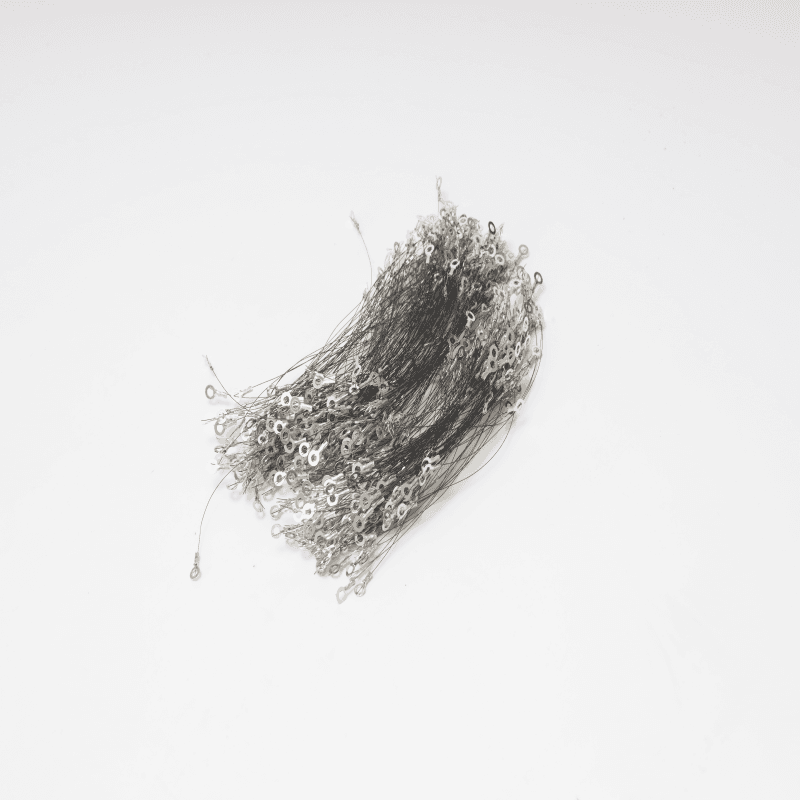

What Is Nitinol Drive Wire?

Our drive wire is made from high-grade Nitinol, a nickel-titanium alloy renowned for its shape memory capability. This shape memory effect allows the wire to return to a preset form when heated, even after extensive deformation. Moreover, Nitinol’s superelasticity means it can undergo significant strain without permanent damage.

Nitinol’s unique properties enable high-precision, space-efficient actuation. Its proven biocompatibility supports safe integration in medical devices, while its mechanical resilience ensures reliable industrial performance.

Enhanced Surface Treatment for Long-Term Reliability

To promote extended service life, every drive wire undergoes fine polishing, which minimizes both surface friction and material fatigue during repeated motion. In addition, optional protective coatings—such as Parylene or thermal oxide layers—can be applied to boost resistance against corrosion and enhance electrical insulation. These surface enhancements make the wire consistently reliable in humid, chemically aggressive, or high-temperature conditions.

Wide Diameter Range for Diverse Applications

Our drive wire is available in a variety of diameters—from 0.1 mm to 2.0 mm—to suit a wide range of use cases:

0.1–0.5 mm: Perfect for fine-tuned movements in micro-actuators or minimally invasive tools.

1.0–2.0 mm: Designed for larger force output in robotics, aerospace systems, or load-bearing components.

We are able to provide dimension customization to precisely align with your all your engineering specifications.

Where Can You Use Nitinol Drive Wire?

Medical Devices

This wire powers tools such as catheter steering systems, self-expanding implants, and surgical devices. Its soft, precise motion reduces tissue damage and improves patient safety.

Robotics

Thanks to its light weight and silent operation, engineers use it for robotic joints, grippers, and prosthetic limbs. Consequently, robots become more efficient and energy-saving.

Aerospace

Drive wires control valves, flaps, and deployable structures that must perform reliably in extreme temperatures—without adding the weight of motors.

Consumer Electronics

It enables smart shape-shifting features in wearables, adaptive eyewear, and automated home devices, offering users futuristic interaction and comfort.

Why Choose Our Nitinol Drive Wire?

✔ Unmatched Quality Control

Each batch undergoes rigorous testing to verify transformation temperature, fatigue resistance, and tensile strength. We meet ISO 13485 and ASTM F2063 standards—so you can trust the consistency.

✔ Custom-Tailored Solutions

From pre-cut lengths to coiled shapes and temperature customization (-20°C to 120°C), we offer flexible options that match your specific actuation needs.

✔ Fast and Reliable Delivery

Popular specs are always in stock, and most orders ship within 72 hours. For large-scale production, we provide discounts and expedited processing.

✔ Expert Engineering Support

We provide free guidance on thermal control, anchoring, and training techniques. As a result, you’ll achieve the best performance with minimal trial and error.

✔ Performance That Gives You the Edge

Streamline your system by replacing bulky motors and hydraulic components with our sleek, high-efficiency drive wire solution.Designs become simpler and consume up to 70% less energy. Moreover, smoother actuation reduces mechanical noise and improves control.

✔ Proven in the Field

More than 200 hospitals and 50 research labs rely on our drive wire. In testing, it withstands over 1 million actuation cycles without failure.

Experience the future of motion with our electrically activated Nitinol drive wire. Contact us to request a sample or consult our engineers about your next project.

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

Back to the products

Reviews

There are no reviews yet.