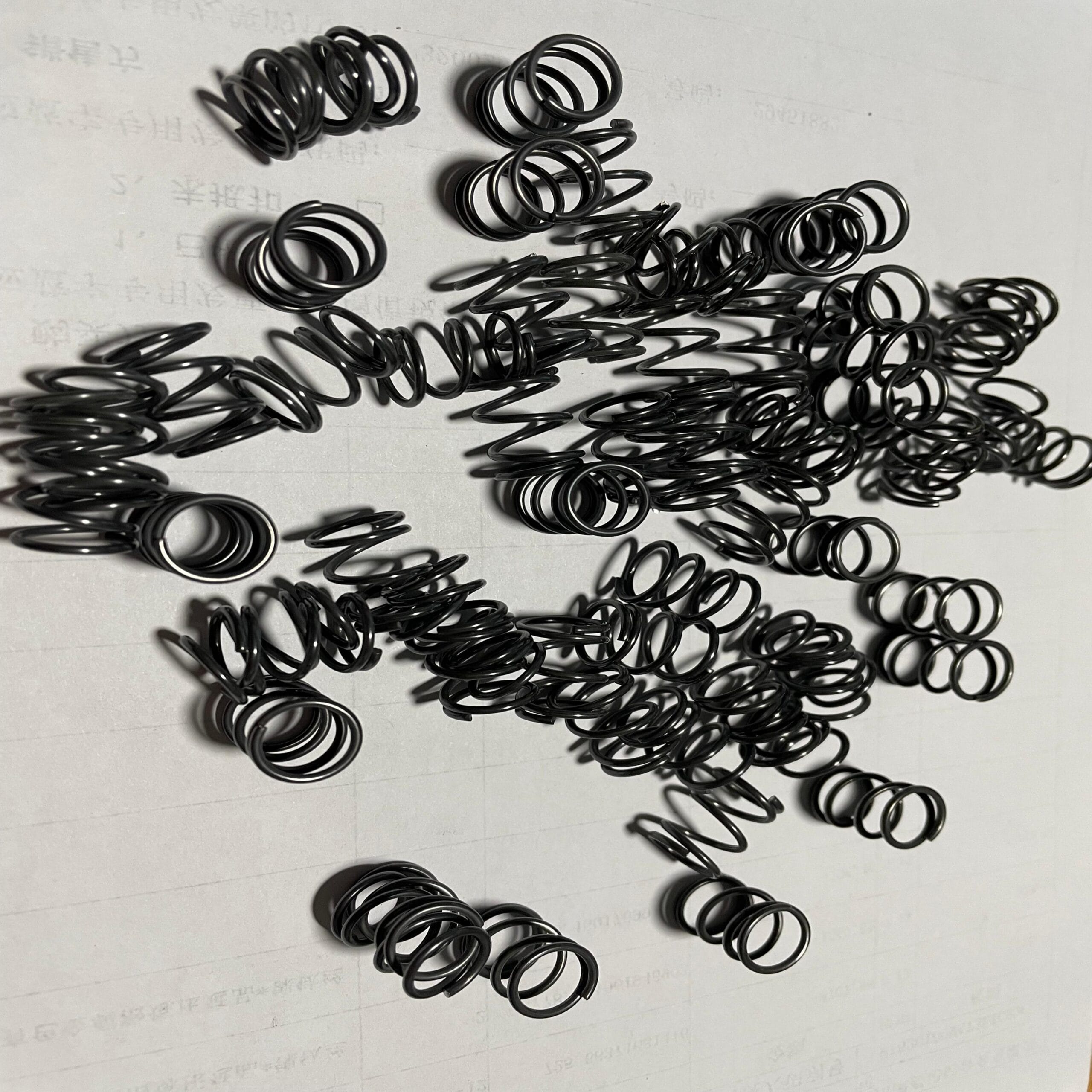

Nitinol Wire Spring for Medical Devices

Shape-Setting Performance You Can Trust

Our nitinol wire spring is a critical component for modern medical devices requiring precise shape memory and superelasticity. Made from premium nickel-titanium alloy, this smart material returns to its pre-set shape when activated by heat—making it ideal for life-saving applications inside the human body. Whether in guidewires, implants, or surgical tools, our springs provide the consistent performance medical professionals rely on.

Superelastic Nitinol Wire – Medical Grade Quality

Crafted from certified medical-grade nickel-titanium, each nitinol wire spring offers:

Superelastic behavior: Recovers its initial geometry immediately after substantial deformation.

Shape memory function: Recovers its programmed shape when heated.

Biocompatibility: Fully compliant with ISO 13485 for safe in-body use.

These properties make our nitinol wire springs ideal for dynamic and complex movements within minimally invasive instruments.

Polished Surface – Safe & Long-Lasting

Our nitinol wire spring features a meticulously polished surface for:

Smooth operation: Minimizes friction in movement-critical devices.

Tissue safety: Designed to lower the likelihood of biological reactions such as irritation.

Corrosion resistance: Withstands bodily fluids and sterilization processes.

A flawless surface extends device longevity while enhancing patient comfort.

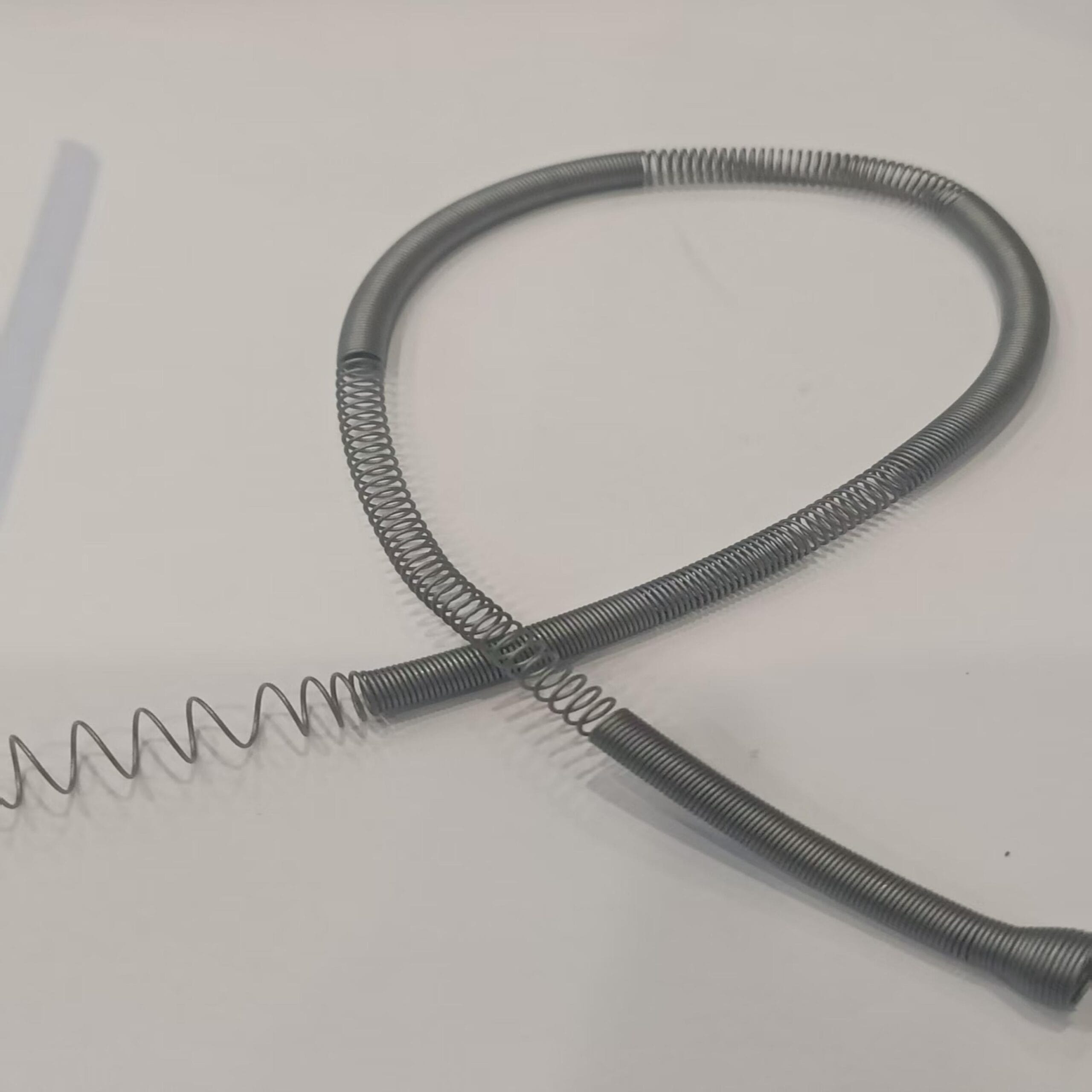

Flexible Diameter Options – From Micro to Macro

Available in sizes from 0.05 mm (0.002″) up to 1.5 mm (0.060″), our nitinol wire springs support a broad range of device designs. We also accommodate custom diameters—ask us about tailored specifications for your prototype or product line.

Broad Medical Applications

Our nitinol wire spring supports innovation across multiple healthcare technologies:

Catheters & Guidewires – Enables flexible, steerable movement.

Stents & Delivery Tools – Maintains compact delivery and precise deployment.

Orthodontic Archwires – Delivers gentle, continuous corrective force.

Surgical Instruments – Powers articulation for laparoscopy and endoscopy tools.

Filters & Occluders – Aids in secure expansion and anchoring.

Bone Compression Devices – Supports healing through sustained pressure.

Implants – Drives mechanical functions inside implantable systems.

Medical R&D –Well-suited for prototyping and evaluating new medical device designs.

Why Choose Our Nitinol Wire Spring?

Exact Shape Recovery – Maintains pre-set shape reliably with every thermal cycle.

Superelastic Consistency – High-force, repeatable deformation behavior.

ISO 13485 Certified – Fully traceable medical-grade nitinol.

Precision Polishing – Enhances safety, biointegration, and lifespan.

Custom & Standard Sizes – Covers micro to large instrument requirements.

Technical Expertise – Engineering support from concept to integration.

Assembly-Ready – Springs arrive clean, shaped, and ready for sterilization.

Start Building Better Medical Devices

Choose our nitinol wire spring for superior performance in shape-setting and flexibility. Trusted by global medical device leaders, our components help deliver the next generation of minimally invasive solutions. Contact us now to bring unmatched shape memory and precision to your design.

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolalloy.com

Mid East Region:getnitinol.com

Reviews

There are no reviews yet.