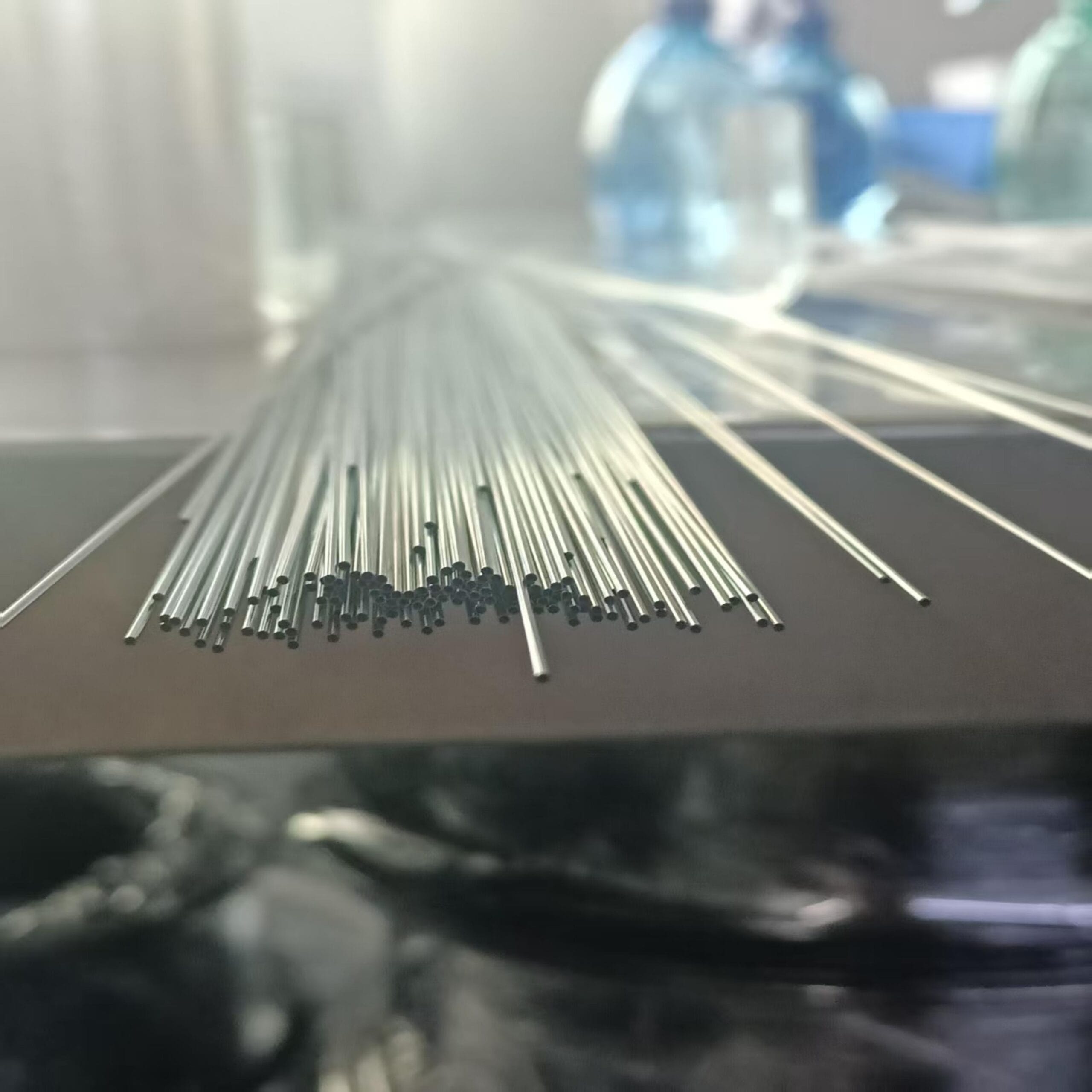

Custom Helical Medical Nitinol Tube for Precision Healthcare Solutions

Premium Nitinol Material for High-Performance Devices

Our custom helical medical nitinol tubes are manufactured using premium nickel-titanium alloy (Nitinol), known for its remarkable superelasticity and shape memory properties. This alloy effortlessly withstands stress and returns to its original form, making it a perfect fit for dynamic and minimally invasive medical devices. We source only high-grade Nitinol to ensure biocompatibility and consistent mechanical behavior in sensitive applications.

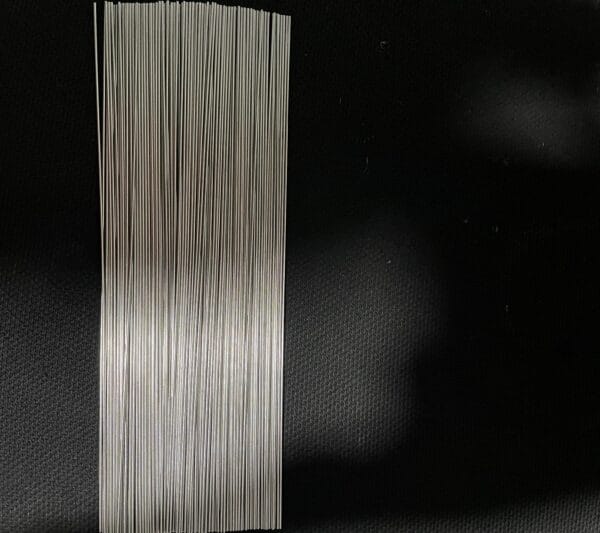

Versatile Surface Finishes for Medical Demands

We offer multiple surface finish options tailored for medical use, each designed to meet stringent industry requirements:

Electropolished: Delivers a clean, ultra-smooth surface that resists corrosion and reduces friction.

Mechanically Polished: Improves structural strength and reliability in demanding surgical environments.

Etched: Ideal for improving coating adhesion and bonding in advanced assemblies.

Each finish is rigorously tested to align with global medical standards for safety, sterility, and performance.

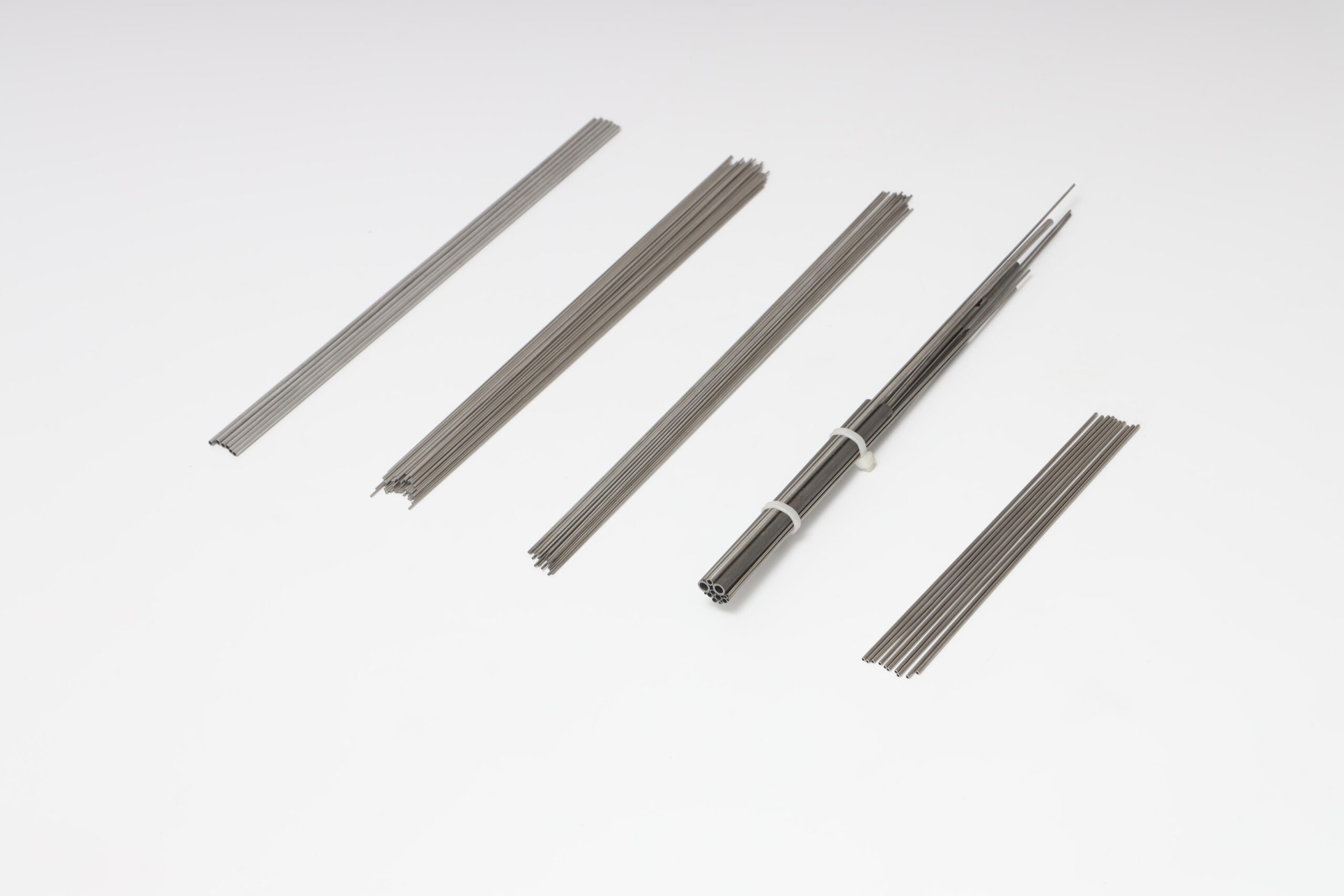

Precision Sizing for Medical Applications

Our medical-grade nitinol tubes adapt to your device requirements with fully customizable dimensions. Designers can specify three core parameters to match surgical or implant needs:

Ultra-Fine to Robust Sizing

Tubes accommodate delicate micro-devices and larger instruments, with outer diameters spanning hair-thin 0.3 mm up to 10 mm.Optimized Lumens

Inner channel dimensions adjust from 0.1 mm (ideal for micro-guidewires) to 8 mm (suited for fluid delivery systems).Strength-to-Weight Control

Wall thickness options balance flexibility and structural integrity, starting at 0.05 mm for ultra-flexible segments up to 1 mm for load-bearing sections.

Custom geometries are supported to meet your device’s unique functional and spatial requirements. These flexible sizing options enable precision for both delicate instruments and high-strength implantable components.

Applications in Modern Medical Devices

Our helical medical nitinol tubes play vital roles across various advanced healthcare technologies:

Catheters: Kink-resistant and highly flexible for complex navigation

Stents: Self-expanding designs to support vessels or airways

Guidewires: Offer precise control in minimally invasive procedures

Orthodontic Archwires: Provide sustained, gentle pressure for tooth alignment

Endoscopic Tools: Improve maneuverability during diagnostics and interventions

Neurovascular Devices: Ensure safety and flexibility in sensitive neurological procedures

Why Choose Our Medical Nitinol Tubing?

Industry Expertise

We focus exclusively on medical-grade nitinol tube development, adhering to ISO 13485 and ASTM F2063 standards. Our engineering team understands the strict requirements of healthcare, including sterilization compatibility and fatigue resistance.

Precision Engineering & Customization

Fine-tune every aspect of your tube: helix pitch, cross-section shape, radial strength, or transition temperature.

Robust Quality Control

Each batch undergoes laser dimension checks, surface analysis via microscopy, and comprehensive mechanical testing. We guarantee structural integrity and repeatable performance.

Efficient Production & Fast Delivery

Prototypes ship in 2–3 weeks, and full-scale production is supported by automated forming and cutting systems. We streamline delivery without compromising precision.

Reliable Support & Global Supply Chain

From concept to final product, our technical experts assist with design challenges. We maintain nitinol inventory for urgent orders and partner only with certified suppliers.

Sustainable & Cost-Effective

We recycle Nitinol scrap, use energy-efficient processes, and comply with RoHS and REACH regulations. In-house processing reduces lead times and lowers costs—bulk discounts available.

Unlock the Full Potential of Your Medical Device

Whether you’re developing a next-gen catheter, a flexible endoscopic tool, or an implant-grade component, our custom helical medical nitinol tube offers the strength, adaptability, and biocompatibility you need. Contact us today to discuss your specific design and performance goals.

▸ Expert Guidance: 24/7 support via nitinolalloy.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.