Nitinol Cable Medical Use for Advanced Surgical Applications

Our nitinol cable medical use products provide exceptional performance for demanding healthcare applications. This specialized nickel-titanium alloy wire delivers unique benefits that medical device engineers consistently prefer for innovative surgical solutions. The material’s exceptional characteristics make it particularly valuable for minimally invasive procedures and implantable medical devices.

Material Advantages for Medical Devices

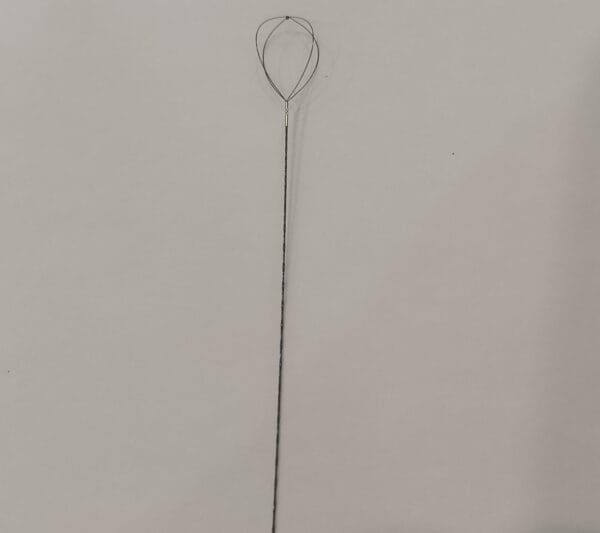

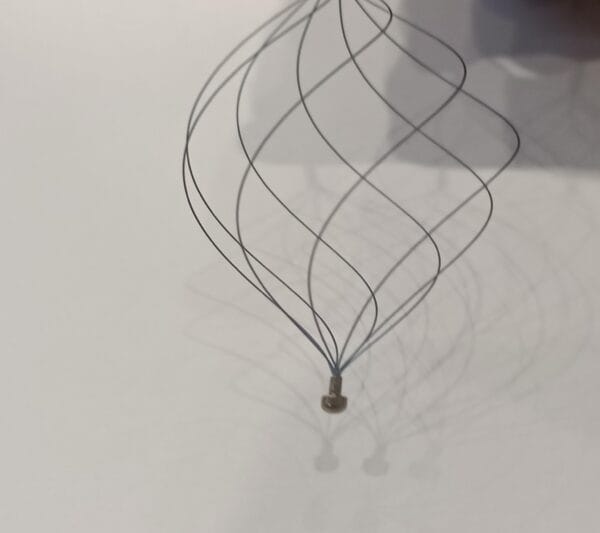

Nitinol cable medical use leverages a remarkable shape memory alloy with extraordinary superelastic properties. This advanced material withstands significant deformation while reliably returning to its original shape without permanent damage. Medical professionals particularly value this kink-resistant characteristic in guidewires and orthopedic tension systems. Furthermore, the material’s consistent performance under body temperature conditions ensures predictable behavior during critical surgical procedures. This reliability translates to enhanced patient safety and improved surgical outcomes across various medical specialties.

Enhanced Performance and Reliability

The exceptional fatigue resistance of our nitinol cable significantly outperforms traditional materials like stainless steel in demanding medical applications. For instance, it can endure millions of movement cycles without failure, making it ideal for long-term implantable devices. Additionally, the material’s excellent corrosion resistance ensures reliable performance in the challenging physiological environment of the human body. Many leading medical device manufacturers now prefer nitinol cables for their proven track record in cardiovascular, orthopedic, and minimally invasive surgical applications.

Technical Specifications and Customization

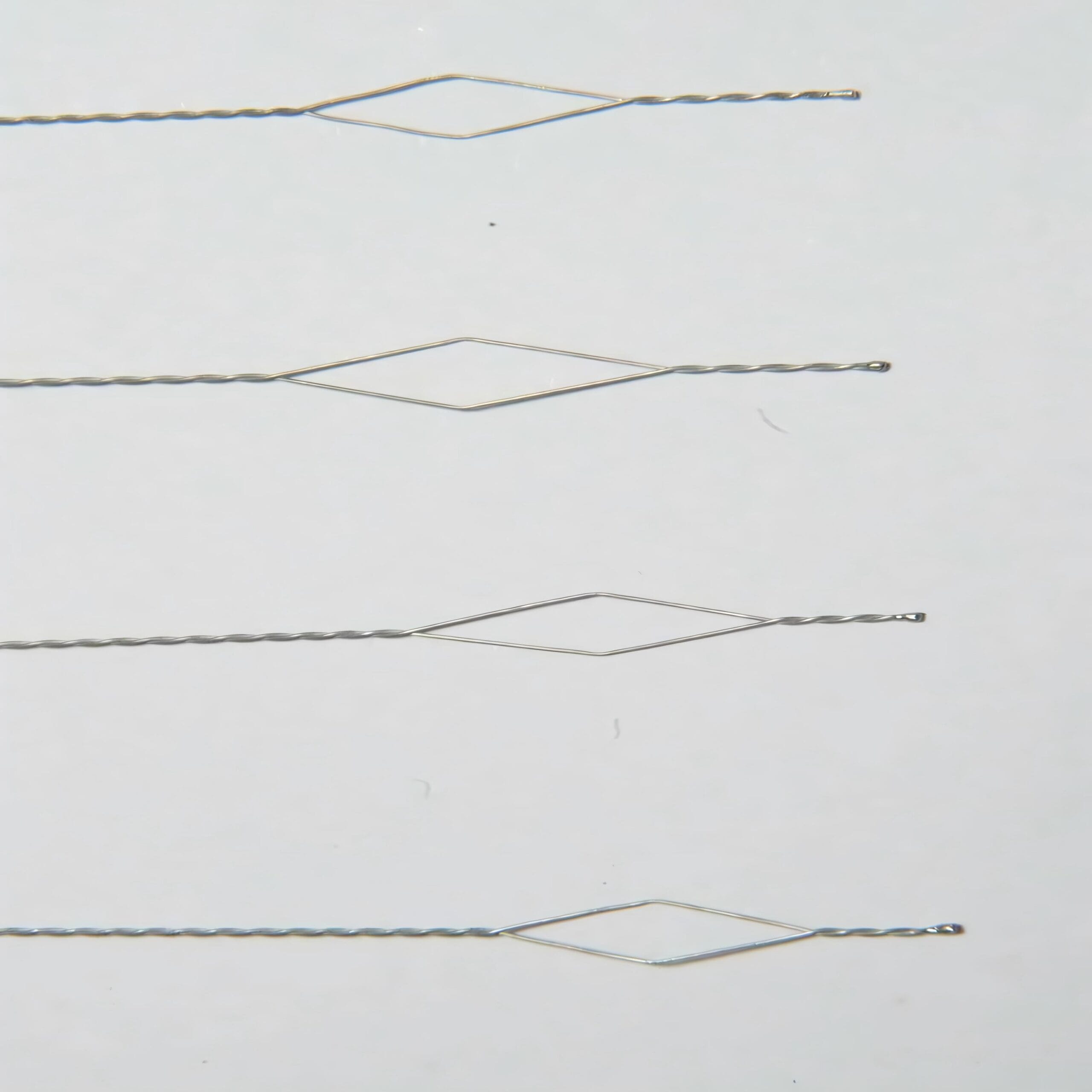

We offer an extensive range of diameters and configurations to meet specific medical device requirements. Our technical team provides comprehensive support for custom nitinol cable medical use applications, from initial concept through final production. The cables maintain consistent performance across various medical sterilization methods, including autoclaving and radiation sterilization. Moreover, our manufacturing processes ensure tight tolerances and superior surface finish for optimal device integration and performance.

Addressing Common Application Questions

Optimal Diameter Selection: We provide an extensive diameter range from ultra-fine to robust sizes for custom medical solutions

Superior Durability: Nitinol significantly outperforms stainless steel in fatigue resistance and flexibility

Biocompatibility Assurance: All our cables meet stringent medical-grade material standards and regulatory requirements

Sterilization Compatibility: Our cables maintain performance through multiple sterilization cycles

Custom Configuration: We offer specialized braiding patterns and termination options for specific applications

Comprehensive Support Resources

Explore our detailed technical data sheets and application guides for comprehensive specifications. Our engineering team offers direct consultation services to optimize your nitinol cable medical use applications. [Internal link to technical resources page] For additional research on nickel-titanium alloy properties and medical applications, we recommend consulting authoritative sources like the ASM International materials database and FDA guidance documents. [Outbound link to ASM International]

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolalloy.com

Mid East Region:getnitinol.com

Reviews

There are no reviews yet.