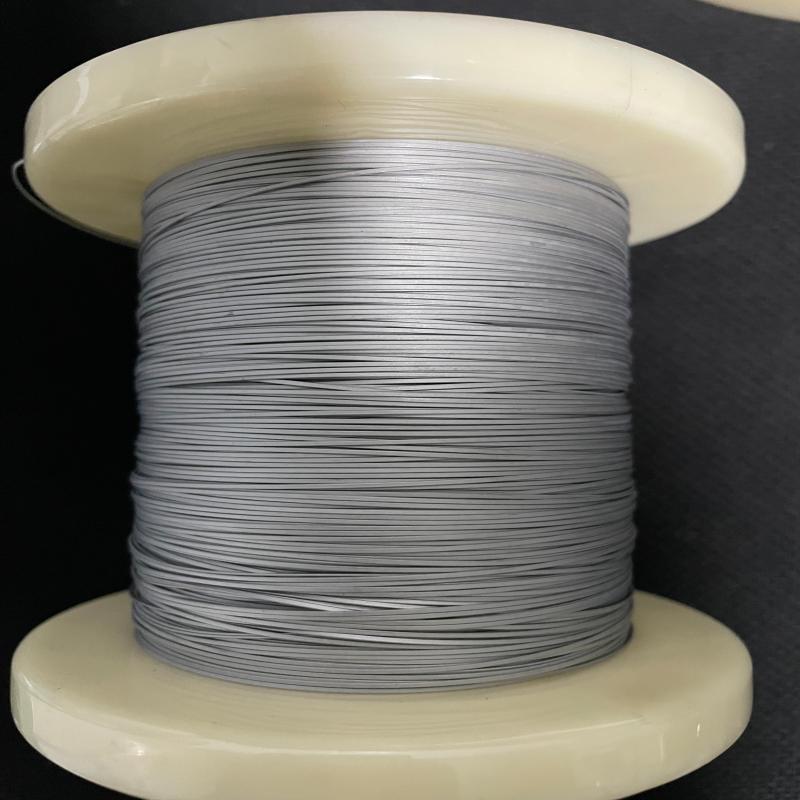

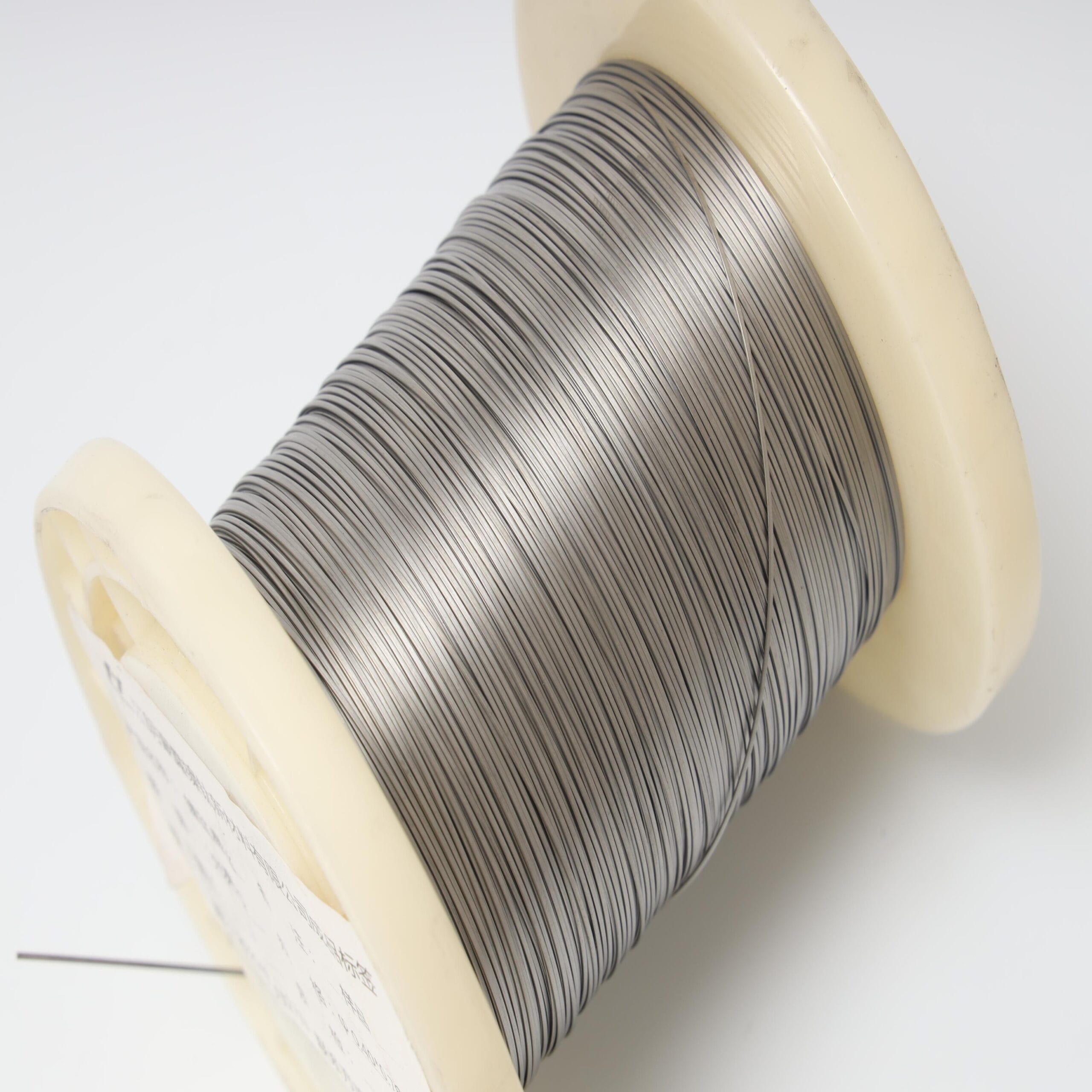

Premium Flat Nitinol Wire for Medical Excellence

Our flat Nitinol wire is crafted from high-purity Nickel Titanium alloy (55% Ni, 45% Ti), offering exceptional superelasticity and shape memory effects. Manufactured in compliance with ASTM F2063 standards, this medical-grade material guarantees biocompatibility, making it safe for long-term implantation and direct contact with human tissue.

Superior Surface Finish for Sensitive Applications

The flat Nitinol wire features a clean, oxidized surface that enhances corrosion resistance and minimizes friction. Our proprietary surface treatment removes contaminants and creates a uniform oxide layer, reducing tissue irritation and improving performance in demanding medical environments.

Wide Size Range for Versatile Medical Applications

Available in dimensions from 0.1 mm to 3.0 mm, our flat Nitinol wires are precision-manufactured with tolerances as tight as ±0.005 mm. We offer custom widths and cross-sectional profiles to meet the design needs of both minimally invasive tools and load-bearing implants.

Critical Applications in Modern Medicine

Engineers and clinicians trust our flat Nitinol wire for various life-enhancing devices:

Guidewires & Catheters: Superior flexibility and kink resistance enable smooth navigation through tortuous vessels.

Stents & Occlusion Devices: Shape memory supports self-expanding configurations for vascular treatments.

Orthodontic Archwires: Delivers consistent force, reducing treatment time and improving patient comfort.

Surgical Instruments: High durability enhances biopsy forceps, snares, and endoscopic tools.

Bone Fixation Plates: MRI-compatible and ideal for trauma repair and orthopedic applications.

Why Choose Our Medical Flat Nitinol Wire?

Certified Quality Control

Manufactured under ISO 13485, every batch is tested for:

Tensile strength (up to 1500 MPa)

Transformation temperatures

Surface purity and uniformity

Elemental composition via XRF

Thermal behavior via DSC analysis

Advanced Customization Capabilities

With over 15 years of Nitinol expertise, we tailor solutions to complex design needs:

Adjustable Af temperatures from -20°C to 50°C

Variable stiffness or tapered geometries

Specialty coatings: PTFE, silicone, and more

Laser-cut micro patterns to improve grip and anchoring

Fast, Compliant Worldwide Delivery

We provide:

Global shipping with full material traceability

REACH and RoHS compliance documentation

Prototypes in as little as 2 weeks

Bulk production in 6–8 weeks

Priority handling for urgent orders

Cost-Effective, High-Performance Wire

Our flat Nitinol wire reduces device failure rates through:

Exceptional fatigue resistance

Lower material waste via precision machining

Bulk pricing for high-volume production—without compromising quality

Technical Support & Partnership

Our engineers offer free consultation to:

Optimize wire specs for your application

Share ANSYS simulation data on fatigue life and stress

Assist with regulatory documentation and prototyping support

Trusted by Leading MedTech Innovators

Over 200 medical device companies incorporate our flat Nitinol wire into FDA-cleared and CE-marked products. Independent case studies show:

30% improvement in stent deployment accuracy

2× longer lifespan for orthodontic wires compared to competitors

Request Your Free Samples Today

Test our flat Nitinol wire for flexibility, surface quality, and thermal response.

📩 Contact us for technical drawings, certificates, and volume pricing.

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolusa.com

Mid East Region:getnitinol.com

Reviews

There are no reviews yet.