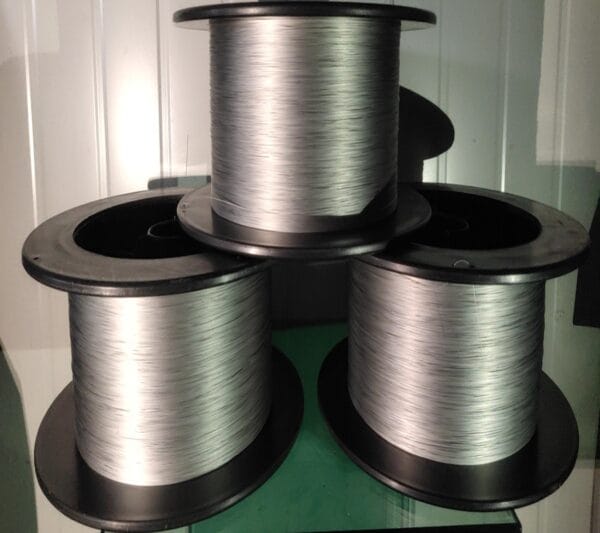

Nanofinished Nitinol Filament for Precision Grinding and Medical Guide Wires

Premium Nitinol Material for High-Performance Applications

Crafted from a high-grade nickel-titanium alloy, our Nitinol wire features exceptional superelasticity and shape memory properties. With a precisely balanced nickel-to-titanium ratio, it delivers outstanding strength, flexibility, and corrosion resistance. Whether exposed to mechanical stress or temperature extremes, this smart material maintains stability and performance.

Nanofinished Surface for Friction-Free Operation

Our nanofinished Nitinol filament is polished to an ultra-smooth surface, reducing micro-imperfections and friction by up to 40% compared to standard wires. This advanced finish enhances durability, minimizes heat generation, and ensures consistent quality across diameters. Ideal for both surgical precision and industrial endurance.

Diameter Range for Every Need

Available in a wide range of sizes to meet diverse industry demands:

Medical Guide Wire Use: 0.1 mm to 0.5 mm — ultra-fine diameters for minimally invasive procedures.

Grinding & Industrial Cutting: 0.6 mm to 2.0 mm — durable diameters for high-load, abrasive environments.

Custom sizes can also be manufactured upon request to match your unique application.

Is a Nitinol Wire a Guide Wire? Absolutely.

If you’re wondering “is a Nitinol wire a guide wire?”, the answer is yes — and it’s one of the best. Its flexibility, kink resistance, and responsiveness make it ideal for navigating complex vascular pathways. Medical professionals rely on it for applications such as:

Angioplasty and stent delivery

Endoscopic procedures

Catheter-based interventions

Broad Applications Across Industries

Medical Devices: Smoothly navigates through veins and arteries without deformation. Perfect for catheters, surgical tools, and implants.

Industrial Grinding & Cutting: Withstands abrasive materials like ceramics, composites, and hardened metals in automotive and manufacturing sectors.

Electronics: Enables smart actuation and microscale movements in sensors and connectors.

Aerospace Components: Resists fatigue and performs under vibration, pressure, and thermal shifts.

Dental/Orthodontics: Retains form through repeated bends—ideal for braces, retainers, and surgical implants.

Why Choose Our Nanofinished Nitinol Wire?

➤ Superior Mechanical Properties

Our wire flexes, twists, and returns to shape without cracking—delivering unmatched precision in every use.

➤ Nanofinish Technology Advantage

The ultra-smooth surface enhances tool life, reduces wear, and ensures safer, more efficient procedures in both medical and industrial environments.

➤ Full Customization Available

We accommodate special requests for diameters, coatings, and mechanical properties. Our quick turnaround ensures your project timelines are met without compromise.

➤ Rigorous Quality Control

Each batch is tested for tensile strength, surface finish, and (for medical-grade wires) biocompatibility. Our certifications include ISO 13485 and ASTM F2063 for full compliance and peace of mind.

➤ Cost-Effective & Long-Lasting

With superior fatigue resistance and corrosion protection, our wire reduces replacement frequency—translating into lower long-term costs and sustained productivity.

➤ Technical Expertise On Demand

Not sure what wire suits your needs? Our engineering team offers full support, from material selection to performance optimization.

Competitive Edge

Unlike rigid stainless steel or brittle polymer alternatives, Nitinol wire combines strength with flexibility. Standard wires may kink or snap under stress — our nanofinished version stays reliable, even under demanding conditions.

Built for Harsh Environments

Whether exposed to saltwater, chemicals, or bodily fluids, our Nitinol filament maintains performance. It’s ideal for high-risk or precision-critical scenarios where reliability is non-negotiable.

Proven in the Field: Real Results

A medical company cut procedure time by 20% using our 0.3 mm Nitinol guide wire.

An aerospace firm reduced sensor failure by 35% after integrating our 1.2 mm wire into its component lineup.

Order Today

Maximize reliability and efficiency with Nanofinished Nitinol Filament Grinding Wire. Contact us for custom samples, pricing, or detailed specs. Let’s redefine performance together—across medicine, industry, and beyond.

Reviews

There are no reviews yet.