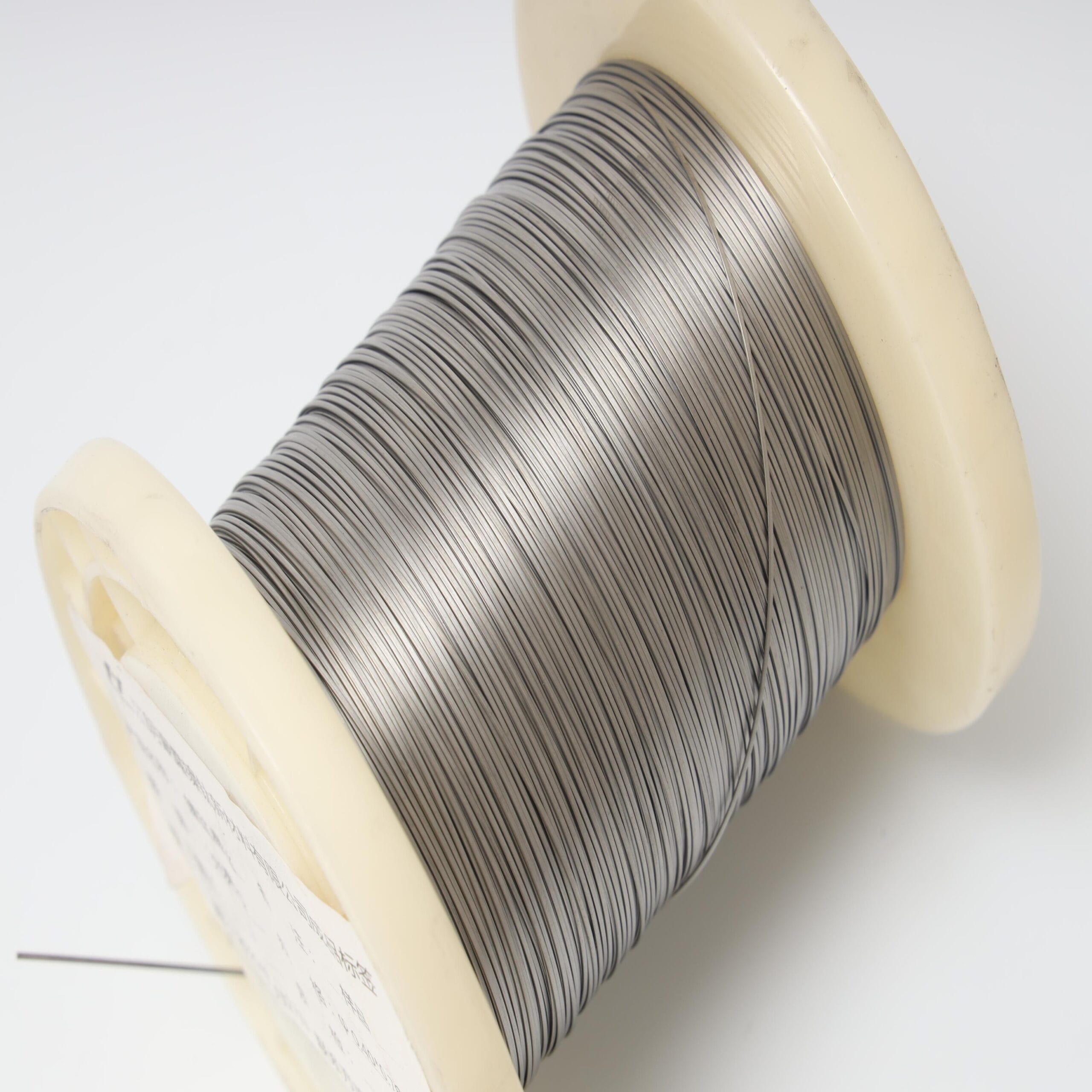

Premium Custom Cross-Section Nitinol Flat Wire | Trusted Nitinol Flat Wire Suppliers

High-Quality Nitinol Flat Wire for Precision Applications

We provide premium custom cross-section nickel titanium flat wire designed for industries that demand exceptional precision, durability, and smart material properties. Our nitinol flat wire combines superior superelasticity, shape memory, and corrosion resistance to exceed the rigorous requirements of medical, aerospace, automotive, and electronics sectors.

Superior Material Quality from Leading Nitinol Flat Wire Suppliers

Crafted from medical-grade Nitinol alloy containing 50-55% nickel, our nitinol flat wire offers unparalleled flexibility, fatigue resistance, and biocompatibility. Fully compliant with ASTM F2063 standards for surgical implants, our wire guarantees consistent performance even under extreme temperatures ranging from -40°C to 200°C.

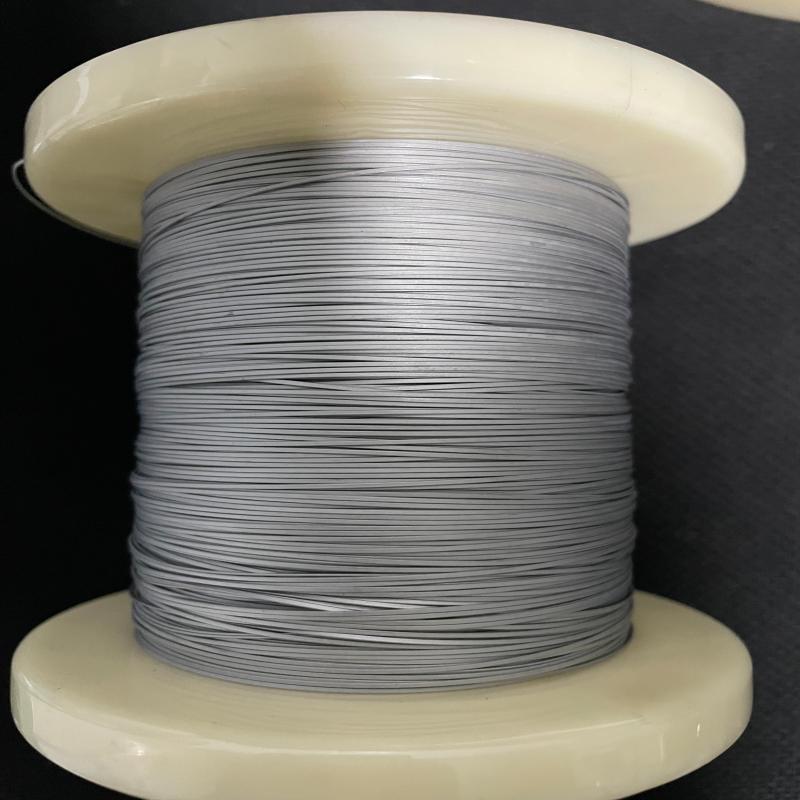

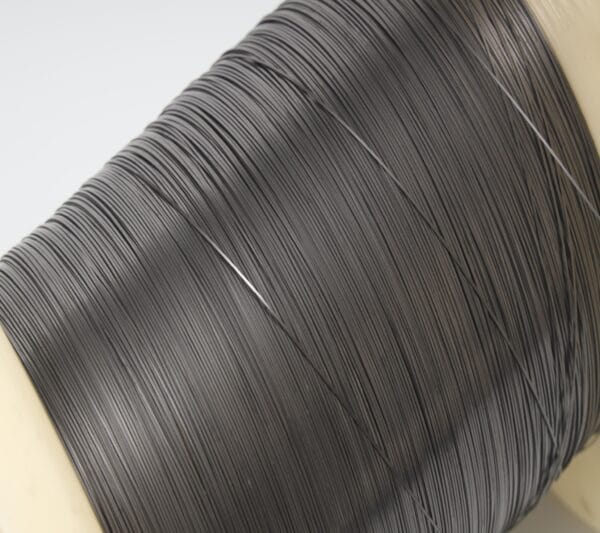

Versatile Surface Finishes Tailored to Your Needs

Select from a variety of surface finishes to perfectly suit your application:

Polished Finish: Smooth, reflective surfaces ideal for medical devices and wear-resistant components.

Etched Finish: Textured surfaces to enhance adhesion for coatings and bonding.

Oxidized Finish: Dark oxide layers reduce glare and improve biocompatibility.

As-Drawn Finish: Cost-effective raw surfaces for industrial uses.

Wide Range of Sizes & Custom Cross-Sections

Our nitinol flat wire is available in thicknesses from 0.05 mm to 3.0 mm and widths from 0.2 mm to 20 mm. We also offer custom cross-sectional shapes such as rectangular, square, and tapered edges to meet the specialized needs of tools, actuators, and sensors.

Applications of Nitinol Flat Wire Across Industries

Medical: Stents, orthodontic archwires, surgical instruments, and biopsy devices utilize Nitinol’s shape memory and MRI compatibility.

Aerospace: Lightweight actuators, vibration dampeners, and satellite components benefit from Nitinol’s high strength-to-weight ratio.

Automotive: Fuel injectors, valves, and safety mechanisms rely on fatigue resistance and thermal stability.

Electronics: Connectors, micro-springs, and MEMS devices depend on Nitinol’s precision and conductivity.

Industrial: Robotic grippers, arms, and energy absorbers perform better with Nitinol’s superelasticity.

Why Choose Us as Your Preferred Nitinol Flat Wire Suppliers?

Expertise: Over 15 years of experience in Nitinol processing and custom fabrication.

Quality Control: Rigorous batch testing ensures precise composition, dimensional accuracy, and mechanical properties.

Fast Turnaround: Prototypes delivered in 10 days; bulk orders within 3-4 weeks.

Global Compliance: Products meet ISO 13485, REACH, and RoHS standards for worldwide distribution.

Custom Solutions: In-house laser cutting, heat treatment, and surface finishing tailored to your design.

Competitive Pricing: Efficient production minimizes costs without sacrificing quality.

Order Your Nitinol Flat Wire from Trusted Suppliers Today

As leading nitinol flat wire suppliers, we make sourcing seamless with responsive customer service, expert technical support, and flexible order quantities. Contact us now for samples, quotes, or technical guidance—let’s bring your innovative projects to life with precision-engineered Nitinol flat wire solutions.

Reviews

There are no reviews yet.