Nitinol Strip Properties – Medical-Grade Nickel Titanium Strip for Advanced Applications

Introduction: Discover Nitinol Strip Properties for Medical Innovation

Nitinol strip properties, such as superelasticity, shape memory, and biocompatibility, are transforming how medical devices are designed and used. These advanced characteristics make Nickel Titanium strips ideal for minimally invasive tools, implants, and surgical instruments where precision, reliability, and adaptability are essential.

Material Composition & Performance Characteristics

Our medical-grade Nickel Titanium strips are engineered with a 55% nickel and 45% titanium composition, offering an exceptional balance of flexibility and durability.

Key features include:

Superelasticity under dynamic stress

Shape memory that allows structural recovery after deformation

High resistance to corrosion and fatigue

Stability across sterilization cycles and temperature extremes

These properties make Nitinol a standout material in demanding healthcare environments.

Surface Treatments to Enhance Performance

We offer specialized surface finishes that further improve the material’s function and compatibility with medical applications:

Mirror Polish (Ra ≤ 0.1 μm): Reduces friction and prevents bacterial buildup

Electropolishing: Increases biocompatibility and corrosion resistance

Passivation or Acid Washing: Cleans and strengthens the material’s protective layer

Each finish is designed to support the reliable performance of Nitinol in clinical use.

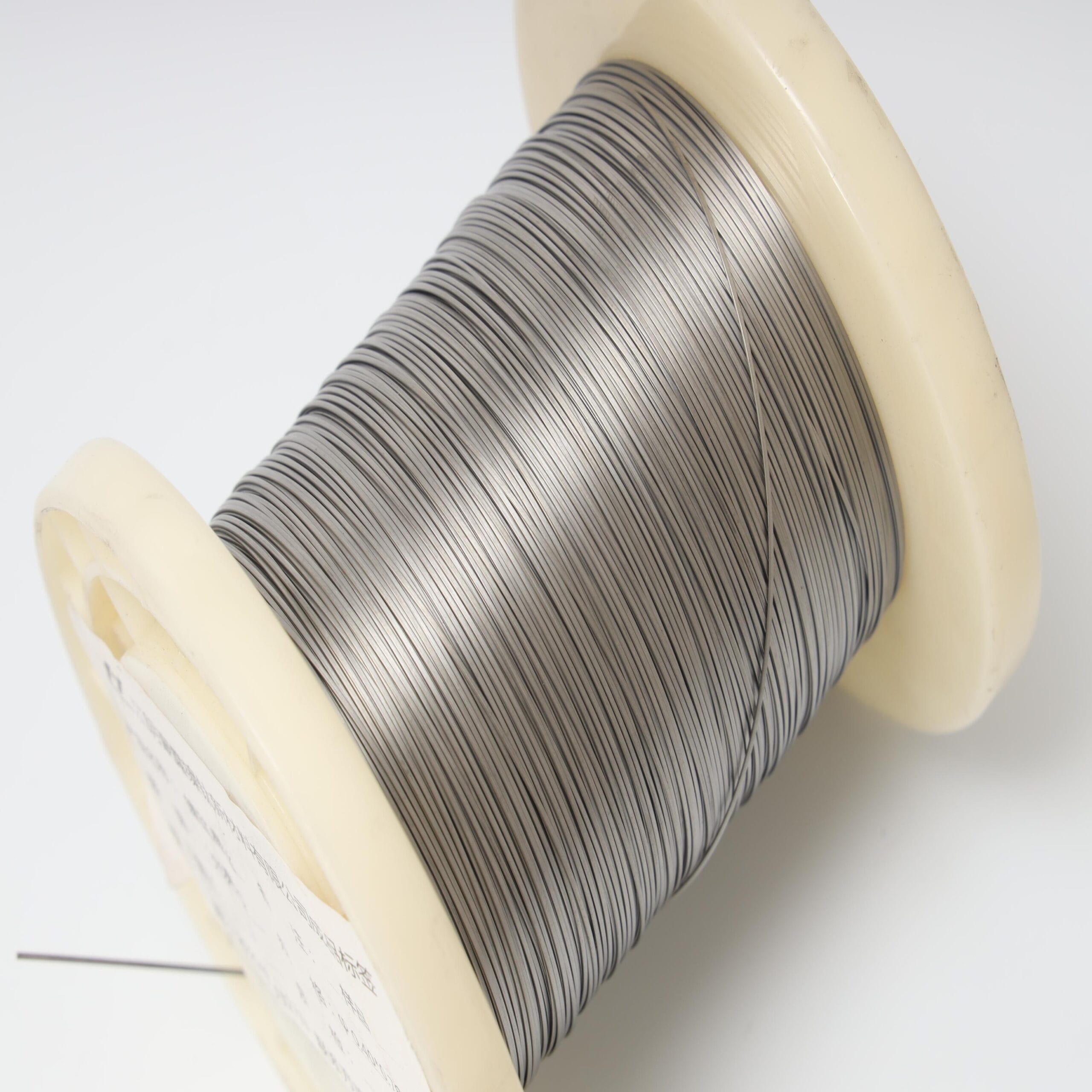

Versatile Sizing for Medical Integration

To suit a wide range of medical designs, our Nitinol flat strips are available in:

Thickness: 0.05 mm – 2.0 mm

Width: 1.0 mm – 50.0 mm

Custom sizing is available for both prototyping and volume manufacturing, ensuring seamless integration into your device.

Applications That Leverage Nickel Titanium Strip Features

Devices for Minimally Invasive Surgery

Catheters, guidewires, and endoscopic instruments benefit from the flexibility and kink resistance of Nitinol.

Orthopedic Components

Spinal rods, bone fixation devices, and bone plates utilize the material’s shape memory to support anatomical movement.

Dental Systems

Orthodontic archwires and retainers use the alloy’s gentle, continuous force for patient comfort and treatment consistency.

Precision Surgical Instruments

From stents to clamps and biopsy tools, these devices rely on Nitinol’s durability and sterilization stability.

Why Choose Our Medical-Grade Nitinol Strips?

1. Quality & Certification

Produced in an ISO 13485-certified facility, our strips undergo strict testing for chemical composition and mechanical properties.

2. Custom Engineering Options

We offer tailored heat treatment and surface processing to match your required Nitinol performance characteristics.

3. Rapid Sample & Production Turnaround

Receive R&D samples within 10 days, with full-scale production delivered in as little as 4 weeks.

4. Industry Expertise

With 15+ years of experience, we support customers through material selection, regulatory prep, and design refinement.

5. Value-Focused Manufacturing

Our efficient production and sourcing strategies allow us to offer premium quality at competitive pricing.

Unlock the Value of Advanced Nitinol Features

Our Nickel Titanium strips are designed to perform in extreme conditions—from saline environments and MRI machines to autoclave sterilization. With a combination of strength, flexibility, and reliability, they provide critical advantages in modern medical engineering.

Ready to innovate with Nitinol?

Contact us today to request free samples or get a quote. Let us help elevate your device with precision-engineered, medical-grade Nitinol solutions.

Reviews

There are no reviews yet.