Nitinol Tubes: Advanced Solutions for Medical Waveguide Systems

Introduction

Nitinol tubes play a critical role in the development of modern medical devices. Known for their flexibility, strength, and biocompatibility, these tubes enable precise, safe, and reliable performance in waveguide systems and minimally invasive procedures.

Nickel-Titanium Material with Proven Biocompatibility

Crafted from premium medical-grade Nickel-Titanium alloy, our Nitinol components exhibit superior shape memory and superelasticity. These properties make them ideal for navigating complex anatomy while maintaining mechanical integrity. The alloy resists corrosion and is certified under ISO 10993 for long-term biological safety.

Enhanced Surface Finish for Smooth Navigation

Each nickel-titanium tube undergoes specialized treatment:

Electropolishing ensures smooth, friction-free surfaces, reducing tissue trauma.

Passivation boosts corrosion resistance in physiological environments.

Optional hydrophilic or anti-thrombogenic coatings can be applied for specific applications.

Alt Text: Nickel-titanium tube with anti-thrombogenic coating used in vascular surgery

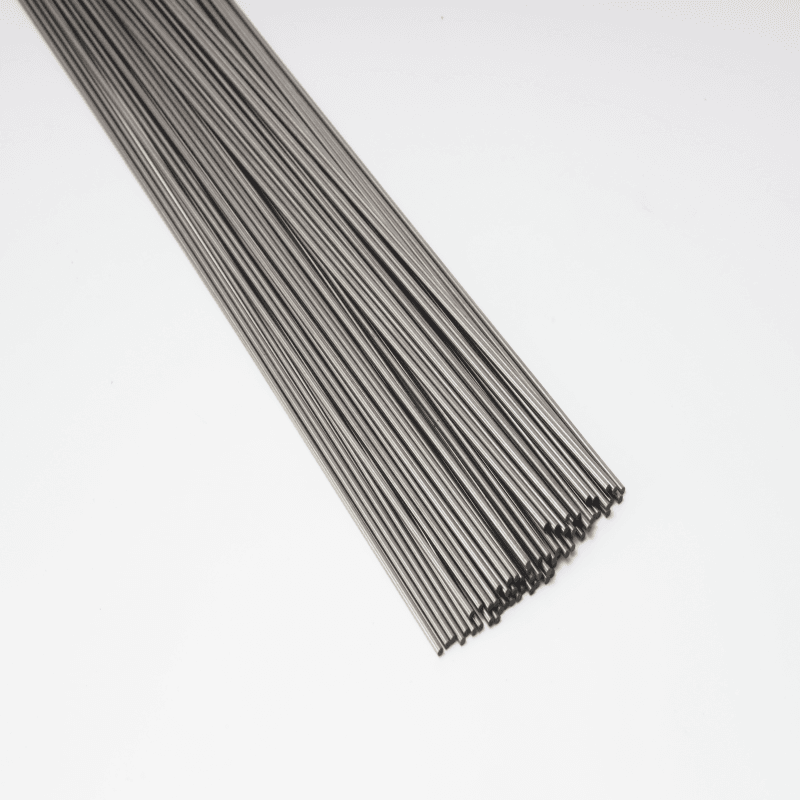

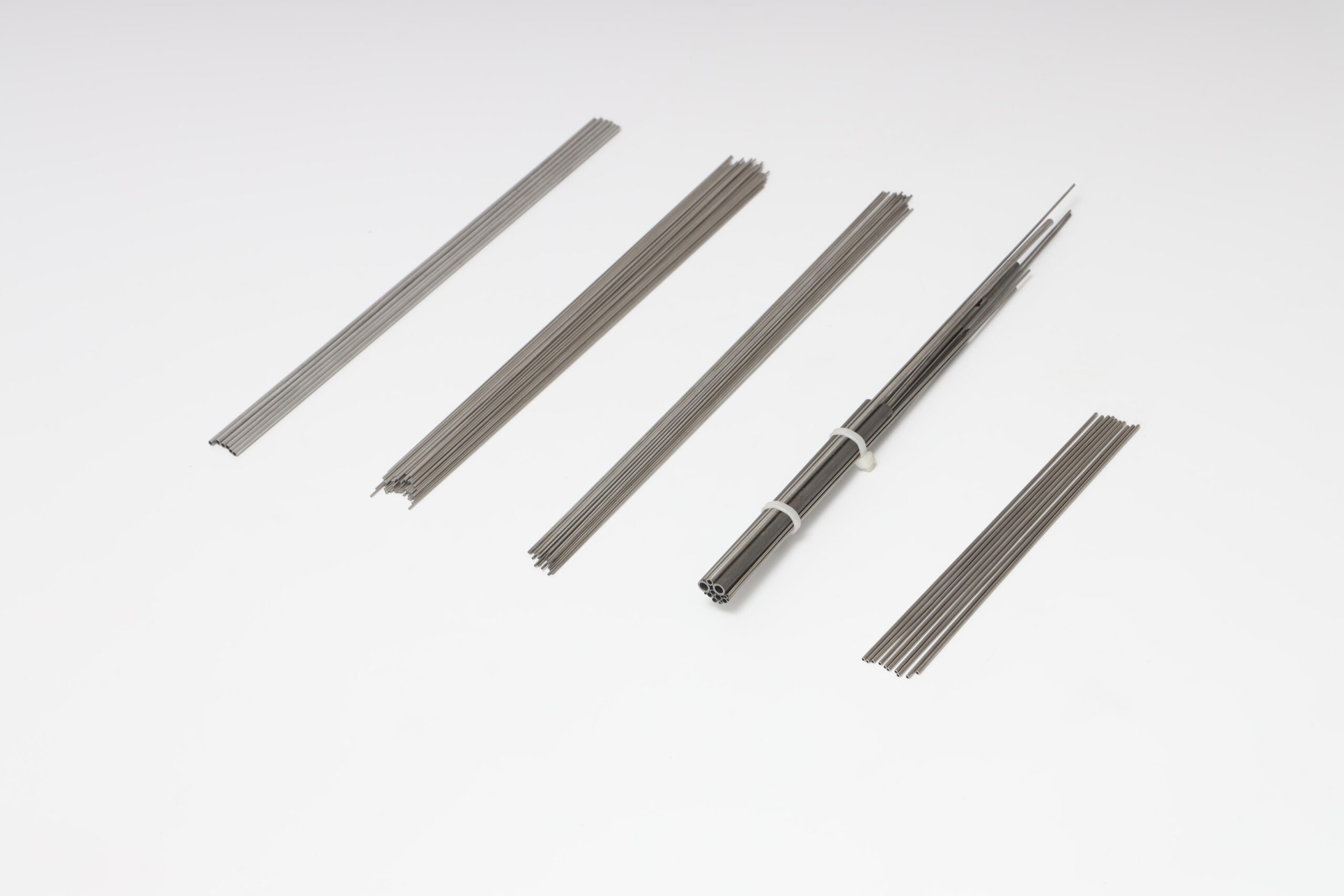

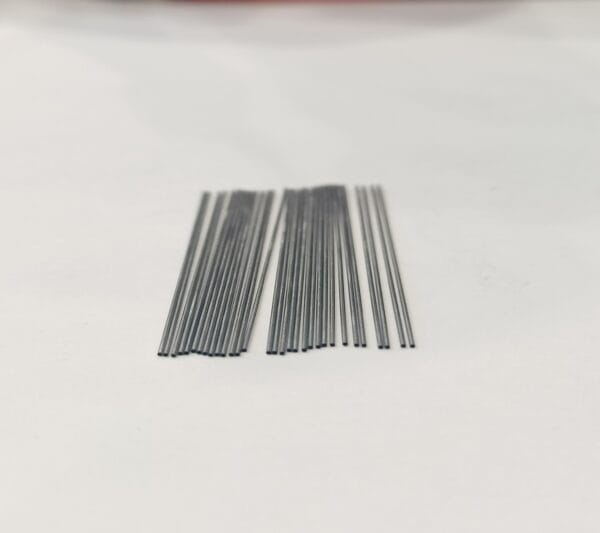

Precision Tube Sizes for Multiple Applications

We offer a wide diameter range to suit diverse medical systems:

Microtubes (0.1 mm – 0.5 mm): Ideal for neurovascular and ophthalmic use

Standard sizes (0.5 mm – 3.0 mm): Used in catheters, endoscopes, and delivery devices

Custom designs: Tapered, curved, or thin-walled versions available on request

Alt Text: Custom-diameter nitinol components for endoscopic and catheter-based tools

Clinical Applications of Nitinol-Based Tubing

Nitinol tubing is integral to next-gen healthcare technology, including:

Catheters & Guidewires: Offer kink-free navigation

Stent Delivery Systems: Enable controlled stent deployment

Endoscopic Instruments: Allow for flexible, precise movements

Surgical Robots: Withstand repeated mechanical stress

Implantable Systems: Deliver drugs or monitor functions reliably

Alt Text: Biocompatible nitinol tube in robotic surgical arm and catheter application

Why Our Nickel-Titanium Tubes Stand Out

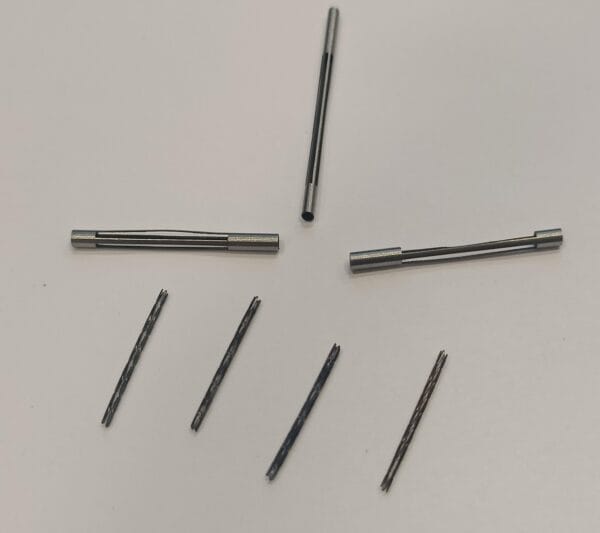

1. High-Precision Manufacturing

Produced via laser cutting and precision forming, our nickel-titanium tubes meet ASTM F2063 and ISO 13485 quality benchmarks. Every tube undergoes fatigue testing and dimensional inspection.

2. Patient-Safe Engineering

Bioburden-controlled environments and edge-deburring ensure safe, clean products. Full ISO 10993 biocompatibility documentation is included with every order.

3. Faster OEM Integration

Polished tubes minimize post-processing time and are compatible with various OEM connectors or handles.

4. Economical & Durable

Bulk availability and high fatigue life reduce unit cost and replacement frequency for reusable systems.

5. Tailored Engineering Support

Our R&D team supports fast design changes, including curvature profiles, wall thickness, and tolerances—with turnaround in under 72 hours.

6. Global Delivery & Certifications

We provide:

Material traceability

RoHS/REACH documentation

Fast delivery to North America, Europe, and Asia

Innovate with Confidence

HAOLU Tech’s Nitinol tubes empower the future of medical innovation—combining flexibility, reliability, and biocompatibility for advanced diagnostic, interventional, and implantable devices.

📩 Contact us today for free samples, technical data sheets, or volume pricing tailored to your needs.

Reviews

There are no reviews yet.