Introduction: The Remarkable Nitinol Wire

Nitinol wire, a nearly equiatomic alloy of Nickel and Titanium, is a cornerstone of modern engineering and medicine. Its name stands for Nickel Titanium Naval Ordnance Laboratory, where it was discovered. This unique material is renowned for two revolutionary properties: Superelasticity and the Shape Memory Effect (SME). These characteristics allow Nitinol to perform in ways traditional metals cannot, enabling breakthroughs across various industries.

As a leading manufacturer, we produce high-precision Nitinol wire with consistent, reliable properties for the most demanding applications.

Unveiling the Properties: Why Nitinol is Unique

- Superelasticity: Can undergo significant deformation (up to 8% strain) and return to its original shape upon unloading, far exceeding the elasticity of steel. This is a stress-induced phase transformation, not a simple elastic stretch.

- Shape Memory Effect: Can be deformed at a low temperature and will “remember” and recover its pre-programmed shape when heated above its transformation temperature.

- Biocompatibility: Excellent compatibility with the human body, making it ideal for long-term implants and surgical instruments.

- Good Fatigue Resistance: Excellent performance under repeated cyclic loading and unloading, crucial for applications like actuation.

- MR-Conditional: Generally safe for MRI environments under specific conditions.

What are Nitinol Wire Applications?

The applications for Nitinol wire are vast, driven by its unique properties. They are primarily divided into two main sectors:

1. Medical & Dental Applications (The Largest Sector)

- Orthodontics (Braces): Nitinol archwires are the gold standard for the initial alignment phase of orthodontic treatment. They apply a continuous, gentle force to teeth, reducing patient discomfort and the number of adjustments needed.

- Endodontics: Nitinol files are used in root canal procedures due to their high flexibility and resistance to fatigue, which reduces the risk of instrument breakage.

- Vascular Stents: Minimally invasive vascular stents can be compressed into a small diameter catheter, inserted into a blood vessel, and then expand to hold the vessel open at body temperature.

- Guidewires: Their kink-resistance and flexibility make them perfect for navigating through intricate anatomy during minimally invasive surgeries.

- Orthopedic Devices: Used in various implants and fixation systems for bones.

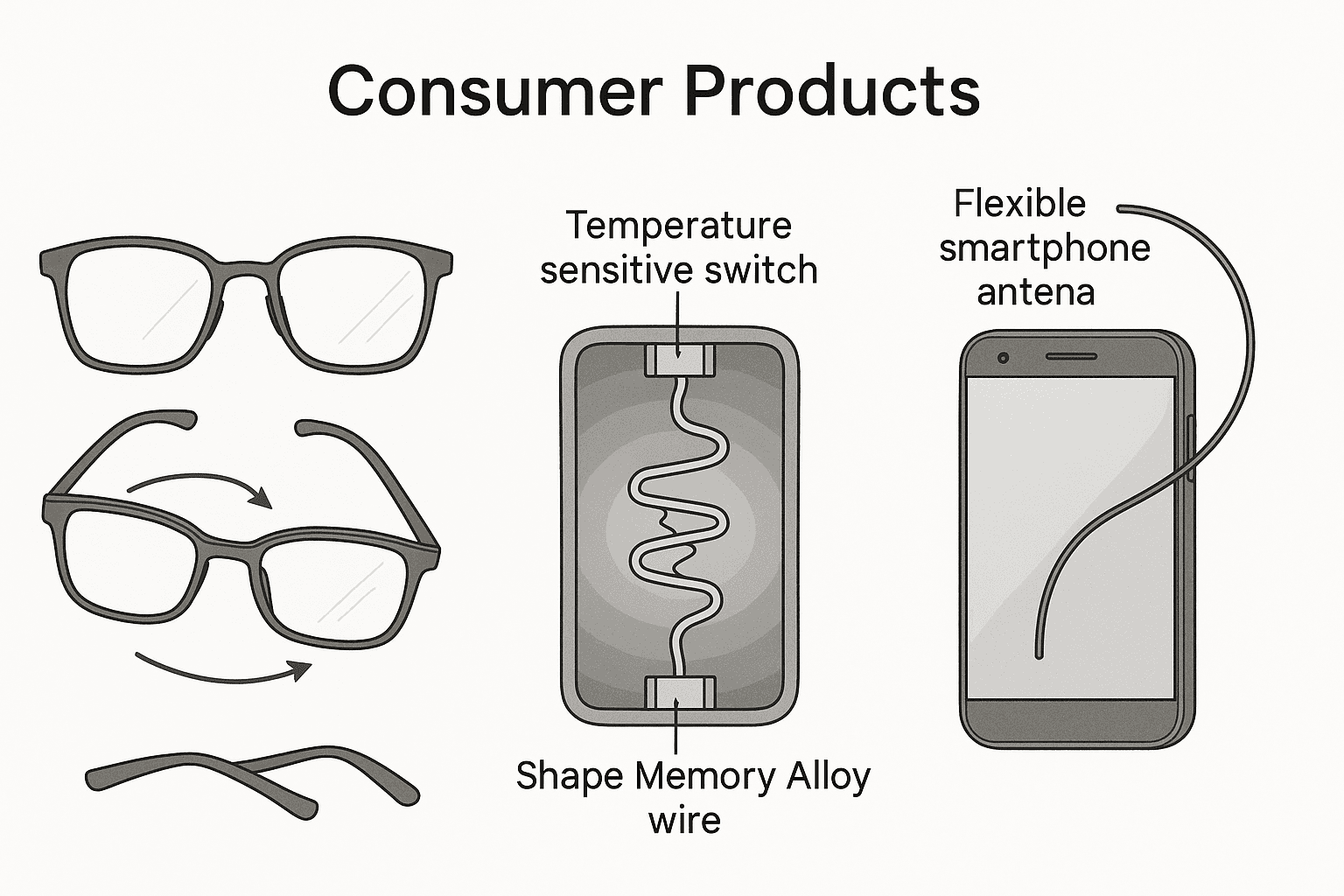

2. Industrial & Consumer Applications

- Actuators & Robotics: Used in robotic grippers, micromanipulators, and actuators that require compact, powerful, and silent movement based on thermal activation.

- Eyeglass Frames: Provides extreme durability and flexibility, allowing frames to be bent and twisted without permanent damage.

- Pipe Couplings (Aerospace): A coupling is expanded at low temperature, fitted over pipes, and then heated to shrink and form a hermetic seal.

- Consumer Electronics: Used in components for cameras and smartphones for its precise actuation capabilities.

Frequently Asked Questions (FAQ)

Q: What is a NiTi wire used for in orthodontics?

A: In orthodontics, NiTi wire is primarily used as superelastic archwires. They are placed in the brackets of braces to apply a consistent, light force over a long range of tooth movement. This makes the initial stage of aligning crooked teeth faster, more efficient, and more comfortable for the patient compared to traditional stainless steel wires.

Q: What is the strongest orthodontic wire?

A: “Strongest” depends on the context. Stainless steel has the highest yield strength (resistance to permanent bending). However, Nitinol wire is the strongest in terms of elastic strength and range. It can exert a useful force over a much greater distance, making it the most effective and “strongest” wire for the initial alignment phase.

Q: What is the nitinol wire for braces?

A: It’s the archwire that sits in the bracket slots of braces. It is often used in the early stages of treatment. Its superelasticity allows it to be tied into misaligned brackets, generating a gentle, continuous force that guides teeth into proper alignment.

Q: How to activate nitinol wire?

A: Activation depends on the property being utilized:

- Superelasticity: Activated by mechanical deformation (e.g., bending, stretching). The wire is activated as soon as it is deformed and will generate a constant force as it tries to return to its original shape.

- Shape Memory Effect: Activated thermally. The wire must be heated above its specific Austenite Finish (Af) temperature to return to its memorized shape. This can be done with a controlled heat source like hot water or a heat gun.

Q: How to cut nitinol wire without a wire cutter?

A: For best results, always use a tool that creates a clean, cold cut to avoid generating heat that can alter the wire’s properties. The best alternatives to standard cutters are:

- A Dremel tool with an abrasive cutting disc (use eye protection!).

- A fine-tooth hacksaw.

- Electron Discharge Machining (EDM) for precision industrial applications.

- Orthopedic pin cutters are designed for cutting tough alloys cleanly.

Q: Is nitinol wire safe?

A: Yes, high-quality, medical-grade nitinol wire is extremely safe and is FDA-approved for many implantable and surgical devices. The nickel is tightly bound in the intermetallic compound, resulting in a very low nickel release rate that is well below the levels that typically cause allergic reactions. However, patients with a severe nickel allergy should consult their physician.

Q: Can you weld nitinol wire?

A: Standard welding techniques (TIG, MIG) are unsuitable as they create brittle fractures and destroy the shape memory properties. The preferred methods are laser welding and resistance welding, performed under a strict inert atmosphere (argon gas) to prevent oxidation. Welding Nitinol requires specialized equipment and expertise and is not a typical end-user process.

Partner with a Expert Manufacturer

Choosing the right nitinol supplier is critical. Our factory specializes in the precise melting, drawing, and heat treatment of nitinol wire. We ensure:

Full Traceability: Complete lot tracking from raw material to finished spool.

Consistent Performance: Precise control over transformation temperatures (Af).

Superior Surface Finish: Optimized for minimal friction and maximum fatigue life.

Customization: Available in various diameters, tensile strengths, and tempers.