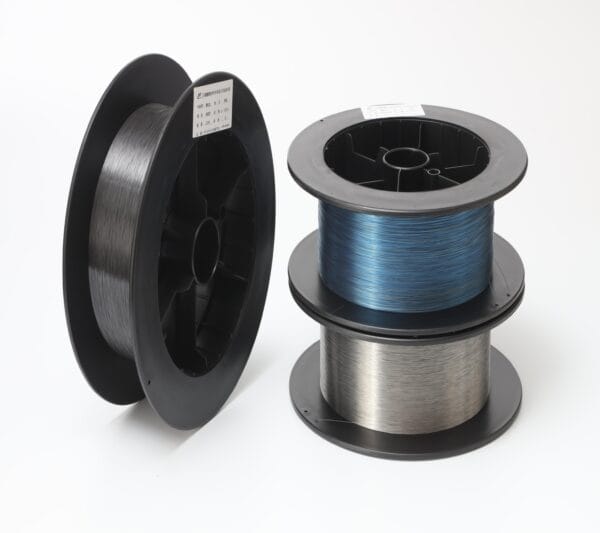

Superelastic Nitinol Wire – Custom Oxidized Micro Wire for Medical & Industrial Use

Introduction: High-Performance Superelastic Nitinol Wire

Our superelastic Nitinol wire is engineered for demanding applications that require both flexibility and strength. This custom oxidized micro wire, made from premium nickel-titanium alloy, exhibits excellent shape memory and superelastic behavior. Designed to recover its original form after deformation, it performs reliably in extreme conditions while resisting corrosion and fatigue—making it ideal for medical, aerospace, and electronic applications.

Material: Shape Memory with Superelastic Properties

The superelastic Nitinol wire is crafted from a nickel-titanium alloy that responds to temperature changes and mechanical stress with precise shape recovery. Its ability to stretch and return to its original form makes it highly effective in devices that require repeatable, dynamic motion. The material also provides outstanding biocompatibility and long-term durability.

Surface Finish: Oxidized for Performance and Protection

A uniform oxide layer is applied through our proprietary oxidation process. This enhances wear resistance, minimizes friction, and boosts biocompatibility for medical environments. The wire’s dark, polished finish protects it from environmental degradation while adding visual appeal.

Diameter Range: Micro Sizes for Precision Applications

We offer this superelastic Nitinol micro wire in ultra-fine diameters from 0.01 mm to 0.5 mm, with fully customizable sizes available. This precision manufacturing supports delicate components without sacrificing mechanical integrity.

Applications: Trusted Across Critical Industries

Medical Devices: Used in stents, guidewires, orthodontic archwires, and surgical tools due to its superelasticity and biocompatibility.

Aerospace: Ideal for deployable structures, actuators, and vibration damping systems.

Electronics: Enables responsive motion in micro-robotics, actuators, and smart sensors.

Consumer Products: Adds flexibility and strength to eyeglass frames, wearable tech, and mobile components.

Why Choose Our Superelastic Nitinol Wire?

Strict Quality Control: Every batch undergoes rigorous testing for superelastic performance, tensile strength, and oxide uniformity.

Custom Engineering: We tailor wire diameters, surface treatments, and packaging to meet unique customer needs.

Fast Delivery: Standard lead time is 2–4 weeks, with rush production available.

Expert Guidance: Engineers assist with application design, material selection, and troubleshooting.

Sustainable Process: Non-toxic oxidation and metal recycling practices reduce our environmental footprint.

Global Reach: Reliable shipping, complete with compliance documentation, to customers worldwide.

Innovation Focus: Continuous R&D in Nitinol oxidation and performance enhancement.

Reviews

There are no reviews yet.