Superelastic Nitinol Tubes | ASTM F2063 | Full Range Sizes

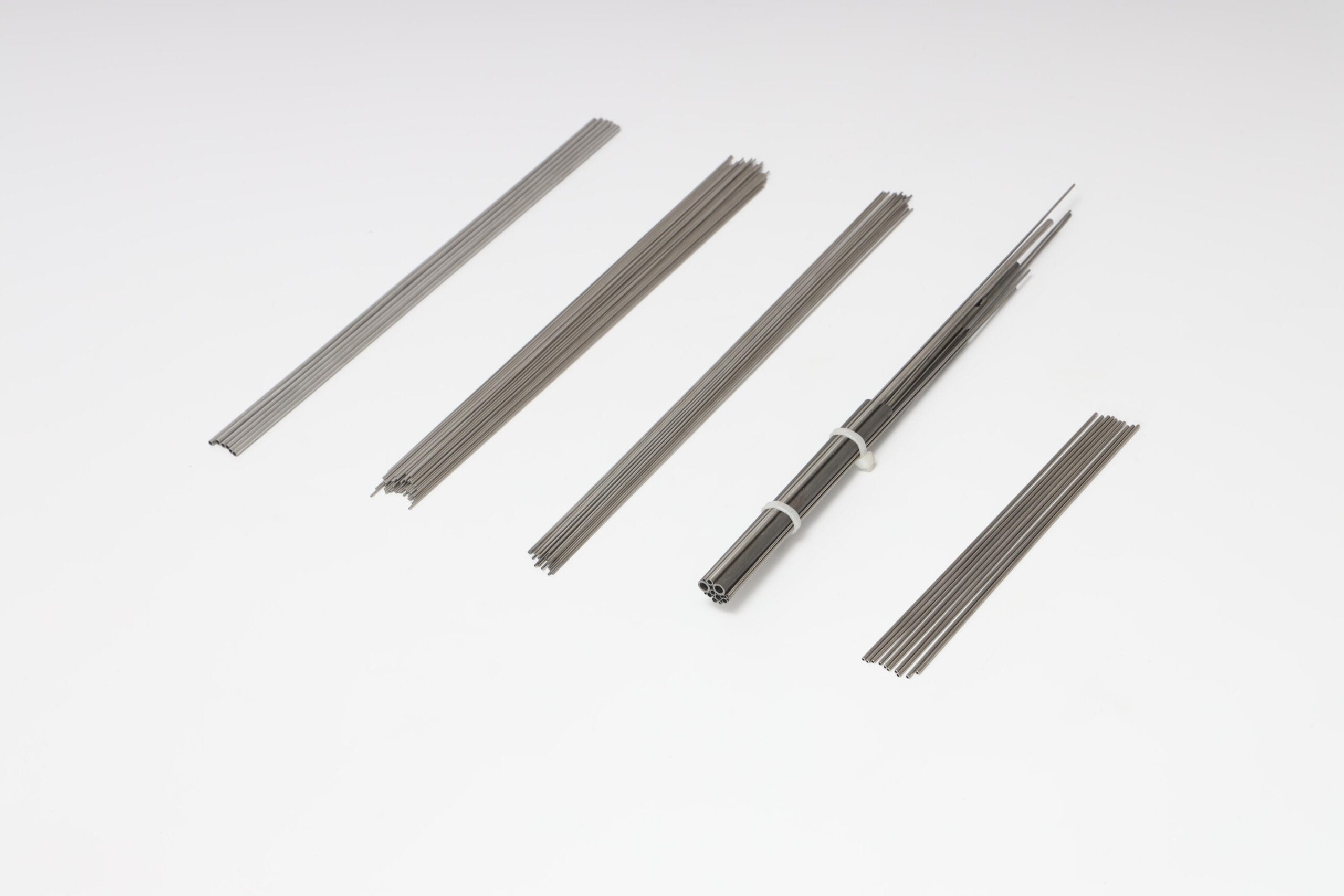

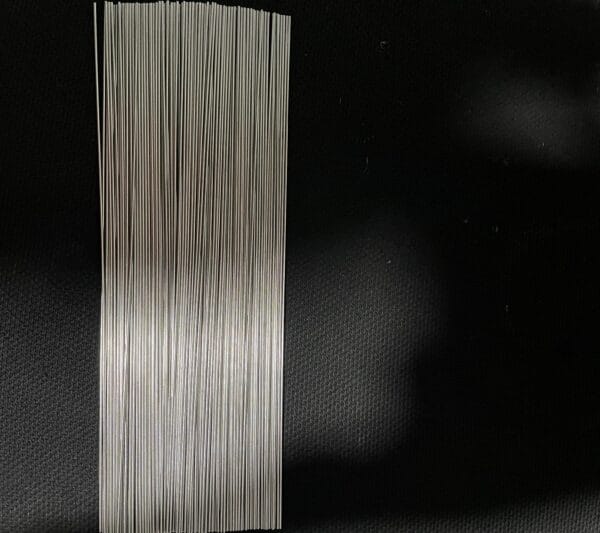

Introduction to Superelastic Nitinol Tubes

Explore our premium range of superelastic nitinol tubes products, meticulously manufactured to meet strict ASTM F2063 standards. We provide comprehensive sizing options suitable for medical, industrial, and advanced research applications. Our nickel-titanium alloy consists of approximately 55% nickel and 45% titanium, delivering exceptional superelastic performance and reliable functionality.

Exceptional Properties and Advantages

Our superelastic nitinol tubes offers remarkable flexibility and shape memory characteristics. It can withstand significant deformation while consistently returning to its original form without damage. Additionally, the material demonstrates excellent corrosion resistance and long-term durability across various challenging environments. With a melting point around 1310°C and density of 6.45 g/cm³, this superelastic nitinol tube maintains stable performance even under the most demanding conditions.

Key Considerations for Material Selection

Prospective users should consider several important factors when selecting superelastic nitinol tubes. Firstly, the material involves higher costs due to specialized manufacturing processes. Although it offers good corrosion resistance, extreme conditions may require additional evaluation. Furthermore, medical applications necessitate thorough biocompatibility testing to ensure safety and efficacy. Finally, recycling presents unique challenges that require specialized approaches different from those used with conventional metals.

Diverse Industrial Applications

The superelastic nitinol tubes serves numerous critical functions across various industries. For instance, medical device manufacturers extensively use it for vascular stents, orthodontic wires, and surgical instruments. Similarly, industrial applications include precision actuators, sensors, and advanced robotic components. Meanwhile, consumer products incorporate superelastic nitinol tube in eyewear and sporting goods. Moreover, aerospace and research sectors particularly value its consistent performance in extreme temperature environments.

Comprehensive Product Specifications

We offer an extensive range of sizing options for superelastic nitinol tube:

Outer Diameter: 0.3mm to 4.0mm

Inner Diameter: 0.2mm to 3.4mm

Wall Thickness: 0.045mm to 0.3mm

Standard Lengths: Up to 2000mm (custom lengths available)

Our superelastic nitinol tube comes in various grades including NiTi-01 and NiTi-02, available in both straight lengths and coils. Additionally, we provide multiple surface finishes including polished, oxidized, and specialized coatings to meet specific application requirements.

Quality Assurance and Support

We maintain stringent quality control throughout all manufacturing processes. Our facility holds ISO 13485 certification, ensuring consistent quality for medical applications. Moreover, we provide comprehensive technical support and custom processing services including precision cutting, specialized bending, and expert welding.

Contact our technical team today to discuss your specific superelastic nitinol tube requirements. We offer samples and volume pricing for various project needs, ensuring you receive the perfect solution for your application.

Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolusa.com

Mid East Region:getnitinol.com

Nitinol Wire – Superelastic and shape memory wires for medical and industrial use

Nitinol Tube – Precision tubing for minimally invasive devices

Nitinol Rope – High-flexibility nickel titanium braided strands

Nitinol Guide Wire – Navigate complex anatomies with kink-resistant precision

Reviews

There are no reviews yet.