Superelastic Nitinol Tube – ASTM F2082 Compliant

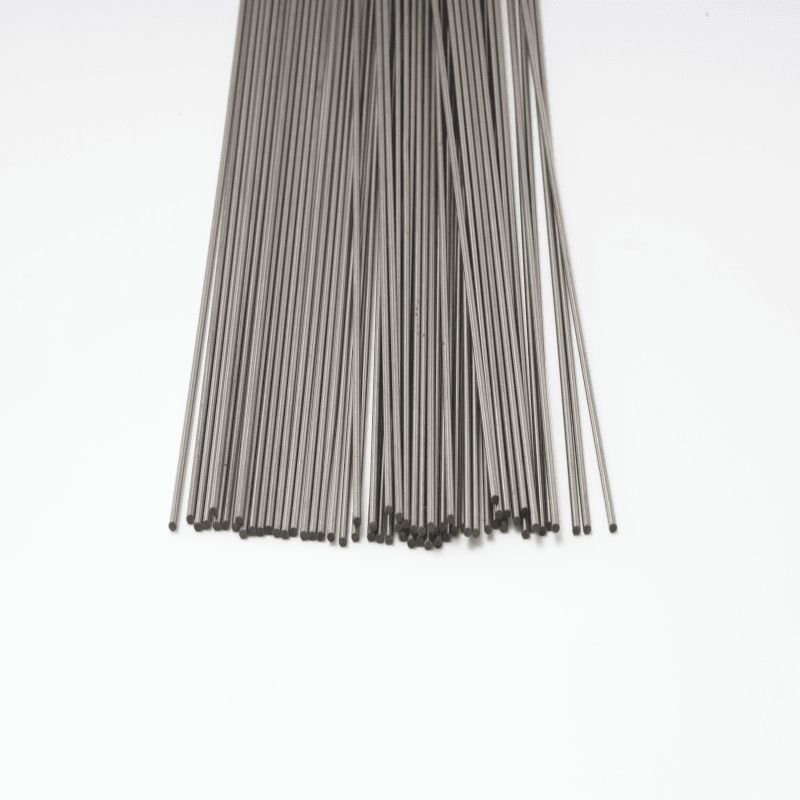

High-Performance Nickel Titanium Tubing

Our superelastic nitinol tube offers a unique combination of strength, flexibility, and shape memory. Crafted from a 50:50 nickel-titanium alloy, it complies with ASTM F2063 for medical-grade biocompatibility. This advanced tubing recovers its shape after deformation, making it ideal for critical medical and industrial applications.

Smooth Surface Finish for Enhanced Performance

Each superelastic nitinol tube is polished to a smooth, uniform surface to minimize friction in dynamic environments. For more demanding uses, we provide optional electropolishing to eliminate micro-defects, enhance corrosion resistance, and prepare the surface for sensitive applications.

Available Tube Dimensions and Custom Options

We produce nitinol tubes in precise sizes to meet a wide range of technical requirements:

Outer Diameter: 0.2 mm – 10 mm

Inner Diameter: 0.1 mm – 8 mm

Custom configurations are available upon request. Our engineers offer tailored support for non-standard dimensions and project-specific tolerances.

Applications of Superelastic Nitinol Tube

Medical Applications

Minimally invasive surgical guidewires

Neurovascular catheter tubing

Orthodontic archwire components

Precision stent delivery systems

Industrial & Technical Uses

Robotic actuator tubing

Aerospace fuel and fluid transfer lines

Downhole tools for oil and gas systems

Electronics & Consumer Devices

Flexible antenna housings

Wearable device sensor frames

Key Advantages of Our Superelastic Nitinol Tubes

Superior Flexibility and Strain Recovery

Our tubes endure up to 8% strain without permanent deformation—delivering consistent performance in high-flex environments where conventional metals fail.

Thermo-Responsive Activation

In medical settings, each superelastic nitinol tube responds to body temperature and recovers its original shape without external heat sources, ensuring efficiency during procedures.

Exceptional Fatigue Life

Nitinol’s superior fatigue resistance ensures our tubing withstands repeated stress cycles, making it ideal for long-term use in critical systems.

ASTM-Compliant Quality & Global Standards

Full Quality Testing

Every tube batch is tested under ASTM F2082, including:

3-point dimensional checks

Bend recovery testing

Surface and chemical integrity assessments

International Certifications

Manufacturing complies with ISO 13485 and RoHS standards. Full traceability documentation is included with each order.

Custom Engineering & Rapid Production

Tailored Tubing Solutions

Choose from various wall thicknesses, taper shapes, and precision tip designs. We offer advanced services including laser cutting, micro-drilling, and custom coatings.

Fast Lead Times

Standard tubes ship in 2–4 weeks. Expedited orders are prioritized upon request.

Durability in Harsh Environments

Our superelastic nitinol tube resists corrosion from bodily fluids, saltwater, and industrial chemicals. Optional PTFE coatings provide added protection for extreme conditions.

Cost-Effective, High-Precision Manufacturing

We reduce material waste by up to 40% through optimized production processes—offering competitive pricing without compromising on quality.

Our superelastic nitinol tube solution brings together cutting-edge material science and high-precision engineering to support next-generation designs in healthcare, robotics, and electronics.

Contact us today for a free consultation and request your sample tubing for evaluation.

Reviews

There are no reviews yet.