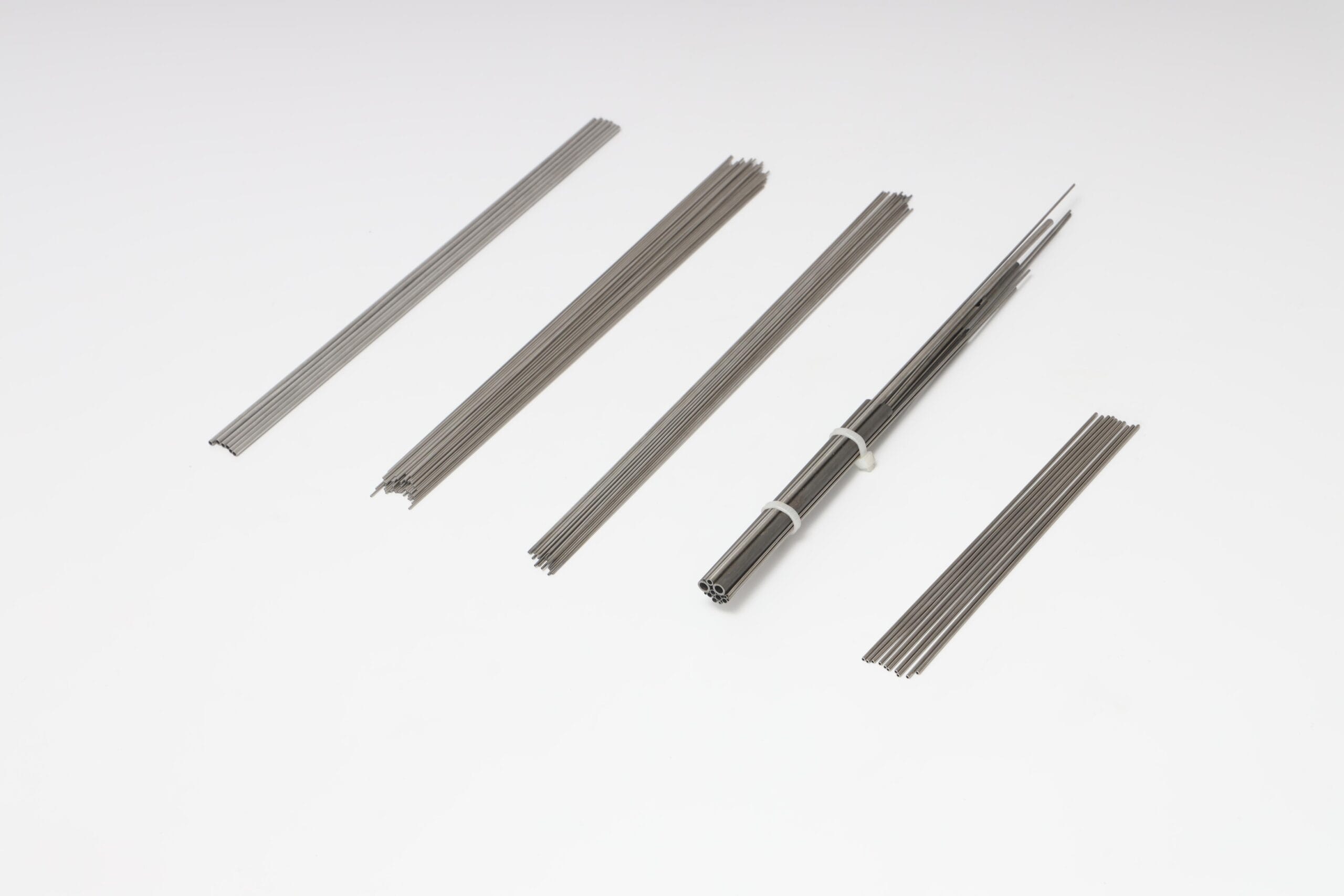

Superelastic Nitinol Tube Solutions for Precision Applications

Engineered for Performance

Superelastic Nitinol tube is a revolutionary solution for industries that demand flexibility, strength, and durability. Thanks to its shape memory and elastic recovery, this nickel-titanium alloy tubing returns to its original form after bending or stress. As a result, it outperforms traditional materials in both medical and industrial environments.

Superior Properties for Critical Uses

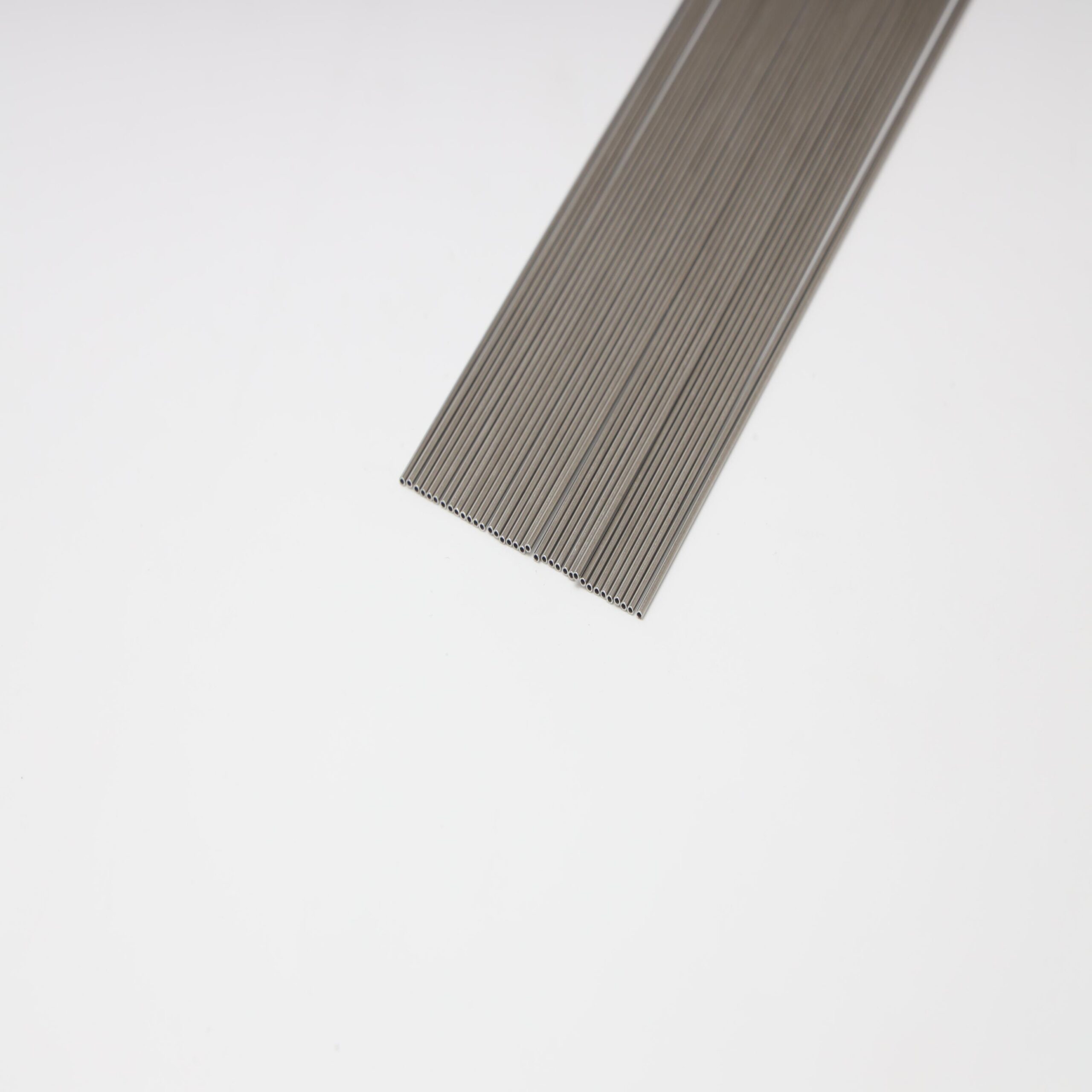

Not only is the superelastic Nitinol tube biocompatible and corrosion-resistant, but it also tolerates extreme stress without permanent deformation. This feature ensures reliable performance in tasks demanding exact measurements and adjustable solutions, such as medical device assembly or precision manufacturing. Furthermore, it withstands repeated use and mechanical strain, which ensures long-term reliability.

Medical Applications That Matter

In the medical field, superelastic Nitinol tubes are used for stents, catheters, and minimally invasive surgical devices. Because the tubing conforms easily to human anatomy, it minimizes discomfort while maximizing function. In addition, its biocompatibility ensures patient safety and meets the most stringent healthcare regulations.

Industrial Performance Where It Counts

Across aerospace, robotics, and automotive sectors, superelastic Nitinol tubing is valued for its resilience. While conventional metals may deform under pressure, Nitinol maintains its shape—thereby reducing maintenance needs and improving efficiency. Industrial systems using this material maintain peak performance through repetitive stress and temperature shifts, critical for automotive suspension parts and power plant equipment.

Custom Options for Every Project

We offer custom fabrication services for your superelastic Nitinol tube needs. Choose from a variety of diameters, wall thicknesses, and lengths. Whether you’re prototyping or scaling up, our team works quickly and efficiently to deliver the exact specifications you require. Additionally, we offer fast lead times and global shipping.

Why Choose Our Superelastic Nitinol Tubes?

Exceptional Elasticity – Recovers shape after stress, ideal for dynamic environments

Certified Quality – Manufactured under ISO and ASTM standards

Precision Manufacturing – Tight tolerances for demanding applications

Fast Turnaround – Custom orders processed in as little as 24 hours

Dedicated Support – Technical guidance from material experts

Reviews

There are no reviews yet.