Precision Micro-Tubing for Next-Generation Devices

Micro-Scale Excellence: Nitinol Waveguide Tube 2.06mm for Minimally Invasive Devices

Material Excellence: Medical-Grade Nitinol

Crafted from premium medical-grade Nitinol (Nickel-Titanium alloy), our Medical Waveguide Tube offers exceptional flexibility, shape memory, and proven biocompatibility. This superelastic material retains strength in micro-scale applications and resists corrosion even in demanding clinical environments.

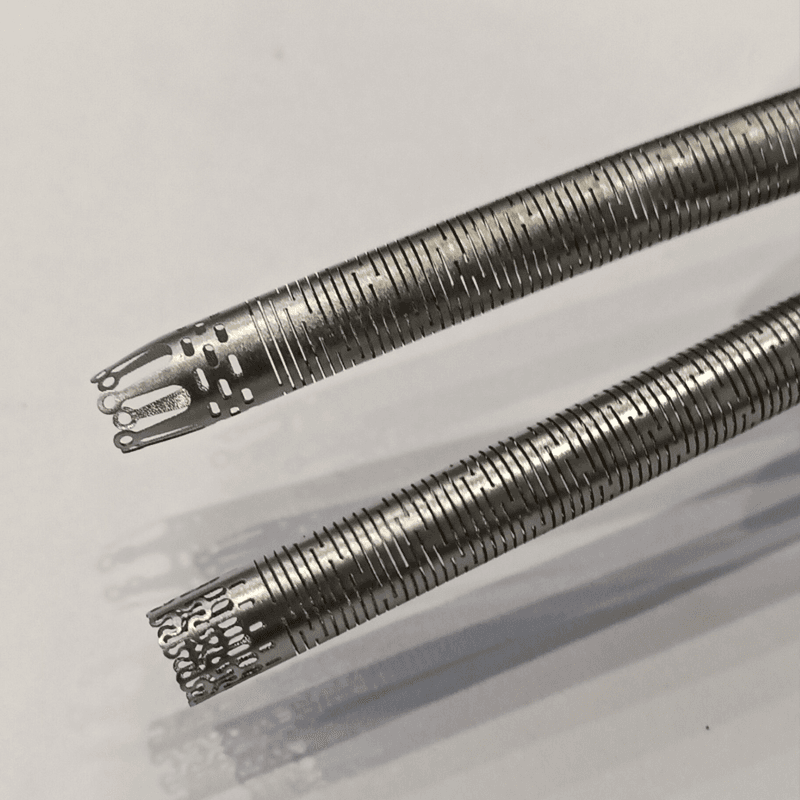

Mirror-Like Finish: Electropolished for Safety and Performance

Each Nitinol tube is meticulously electropolished to achieve a flawless, mirror-like surface. This ultra-smooth finish reduces friction, minimizes bacterial adhesion, and enhances durability—ideal for safe integration in minimally invasive procedures.

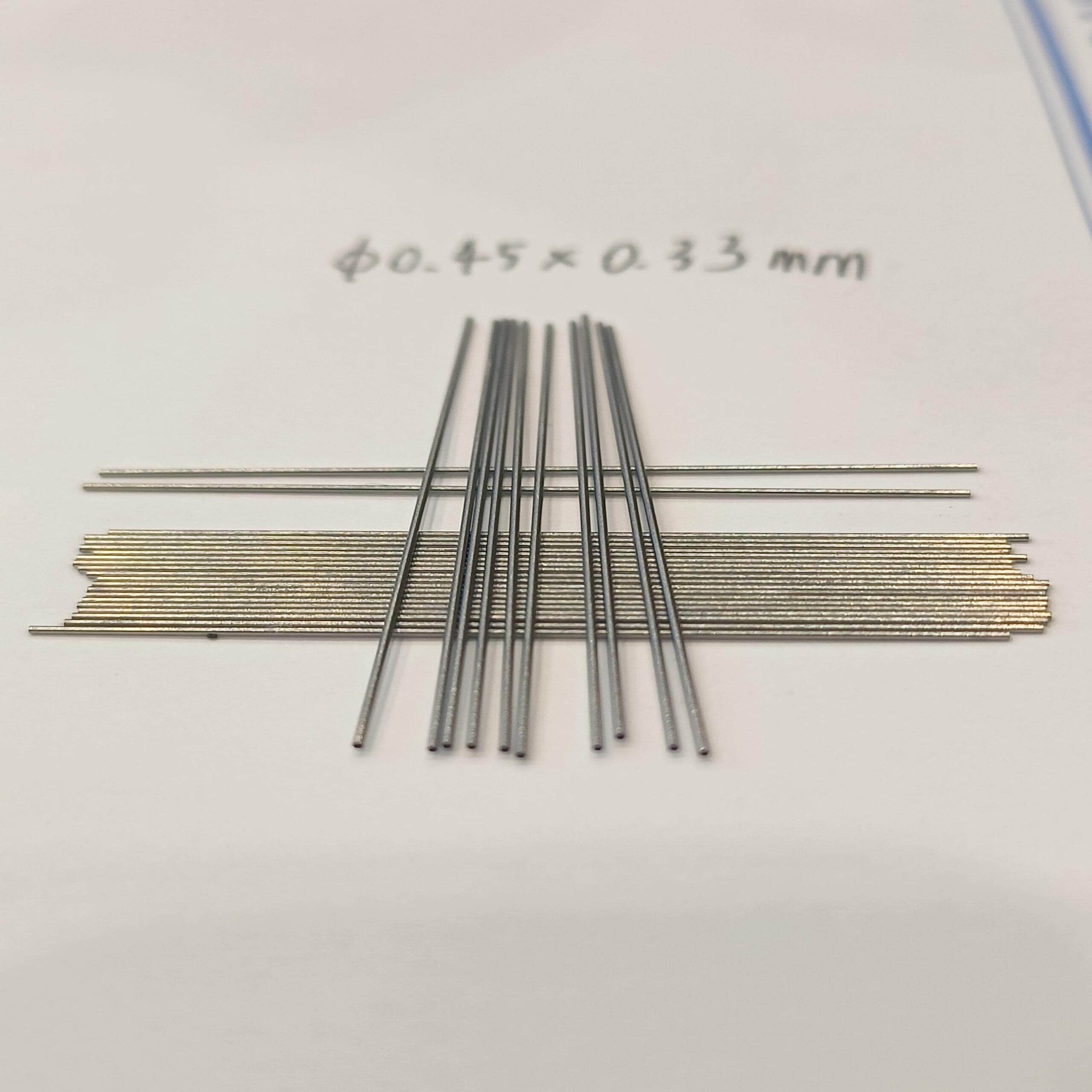

Smallest Diameter Nitinol Tube: Designed for Precision

With an outer diameter of just 2.06mm and an inner diameter of 1.92mm, this product represents the smallest diameter Nitinol tube in the industry. Its ultra-thin wall (0.07mm) delivers unmatched flexibility without compromising structural integrity—perfect for high-precision medical applications.

Micro-Scale Applications: Engineered for Innovation

Optimized for minimally invasive procedures, this Nitinol waveguide tube is commonly used in:

Endoscopic and robotic surgical tools

Cardiovascular and neurovascular catheters

Fiber optic laser delivery systems

Micro-diagnostic sensors and guidewires

Its compact size enables navigation through the narrowest anatomical pathways, such as coronary arteries and neural passageways.

Why Choose Our Smallest Diameter Nitinol Tube?

➤ Unrivaled Precision

Manufactured with ±0.02mm tolerances using advanced laser-cutting techniques—ensuring consistency across high-volume production.

➤ Proven Biocompatibility

Electropolished to meet ISO 10993 standards for implantable devices, ensuring safe tissue interaction and minimizing rejection risks.

➤ Durability in Extreme Conditions

Withstands up to 8% strain without deformation. Supports standard sterilization protocols (autoclave, EO) and functions reliably in MRI/CT conditions.

➤ Customization Ready

Custom wall thicknesses, tapered ends, and surface coatings (PTFE, hydrophilic) available. We provide rapid prototyping, pressure/fatigue/leak testing, and full engineering support.

➤ Regulatory Compliance

Meets FDA, CE, and RoHS requirements. Delivered with complete traceability and certification documentation.

Empowering the Future of Minimally Invasive Care

As medical technology evolves, the demand for smaller, more precise components grows. Our smallest diameter Nitinol tube pushes the boundaries of what’s possible—enabling safer, faster, and more effective procedures in cardiology, neurology, urology, and beyond.

Engineers and OEMs trust our micro-tubing for its torque control, kink resistance, and integration into advanced devices like stent delivery systems, steerable catheters, and surgical micro-robots.

Quality You Can Trust

Every batch is rigorously inspected for dimensional accuracy, mechanical properties, and surface integrity. Produced in our ISO 13485-certified facility, we ensure quality at every step.

Choose Innovation. Choose Precision.

Push the boundaries of micro-medical innovation with our ultra-thin Nitinol tube. Empower your next-generation minimally invasive solutions with unmatched precision and flexibility.

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolalloy.com

Mid East Region:getnitinol.com

Reviews

There are no reviews yet.