Shape Setting Nitinol Components for Advanced Engineering Solutions

High-Quality Shape Setting Nitinol Material

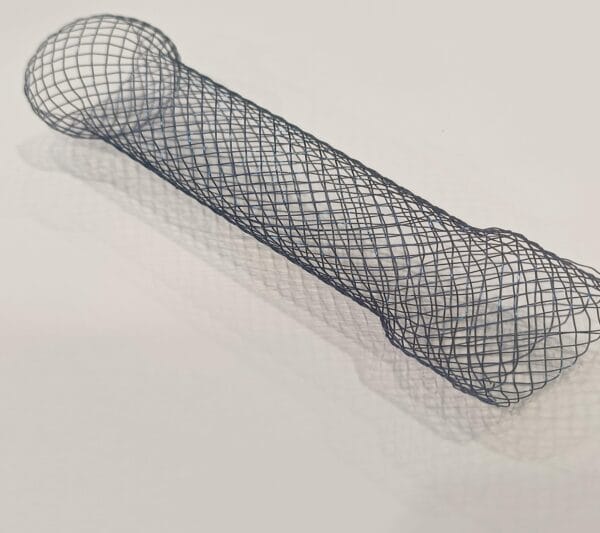

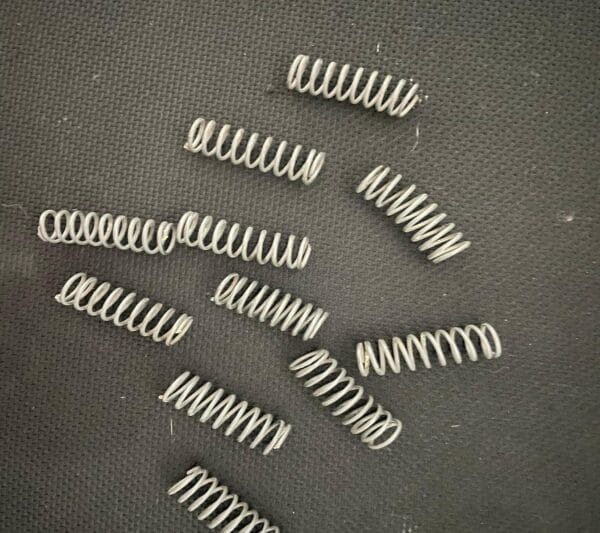

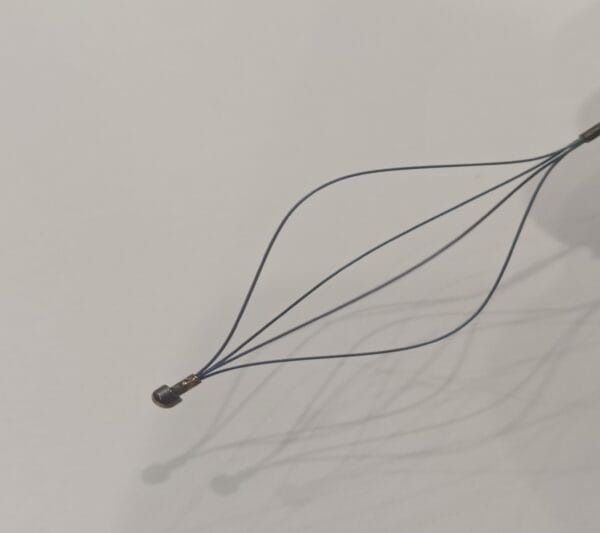

We use premium nickel-titanium alloy, widely known as shape setting Nitinol, to manufacture components that deliver outstanding performance. Thanks to its superelasticity and shape memory, this material enables parts to return to their original form after deformation. Furthermore, it offers exceptional corrosion resistance and handles extreme temperatures with ease. As a result, it is highly suited for demanding applications across various industries.

Expert Surface Finishing Enhances Performance

To maximize durability and function, we apply advanced surface finishing methods such as electropolishing and passivation. These techniques not only improve corrosion resistance but also reduce friction and contamination risk. Consequently, our components meet the strict standards required by the medical and aerospace sectors. Moreover, enhanced surface quality contributes to longer product life and consistent performance in critical environments.

Wide Diameter Selection to Meet Diverse Applications

We manufacture shape setting Nitinol components with diameter options spanning 0.1 mm to 5.0 mm, supporting both micro-scale and larger-scale designs.Whether you’re designing delicate medical tools or robust industrial actuators, our product range supports both extremes. Moreover, we offer fully customizable dimensions to match your precise specifications. This adaptability ensures we can meet the demands of complex and varied engineering applications with ease.

Applications Across Key Industries

Medical Devices: Improve flexibility and biocompatibility in guidewires, archwires, and minimally invasive instruments.

Aerospace: Dependable connectors and actuators that endure temperature shifts and mechanical stress.

Automotive: Enhance fuel systems, sensors, and safety mechanisms with fatigue-resistant materials.

Consumer Electronics: Create compact and durable designs for wearables, connectors, and hinges.

Industrial Automation: Optimize robotics, valves, and thermal actuators with precise motion control.

Why Choose Our Shape Setting Nitinol Components?

We bring over 13 years of expertise in shape setting Nitinol manufacturing.With deep industry knowledge, our team collaborates directly with clients to develop precisely engineered solutions for their unique application needs.In addition, we ensure fast lead times without compromising quality. Each component undergoes rigorous testing to verify dimensional precision, surface finish, and mechanical integrity. With a global client base across healthcare, aerospace, and technology sectors, we are a trusted partner in precision engineering.

In the end, our goal is to make innovation more accessible by uniting intelligent material science with precision-driven engineering. Reach out to us today and discover how our shape setting Nitinol components can elevate the performance and reliability of your next design.

▸ Expert Guidance: 24/7 support via nitinolalloy.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.