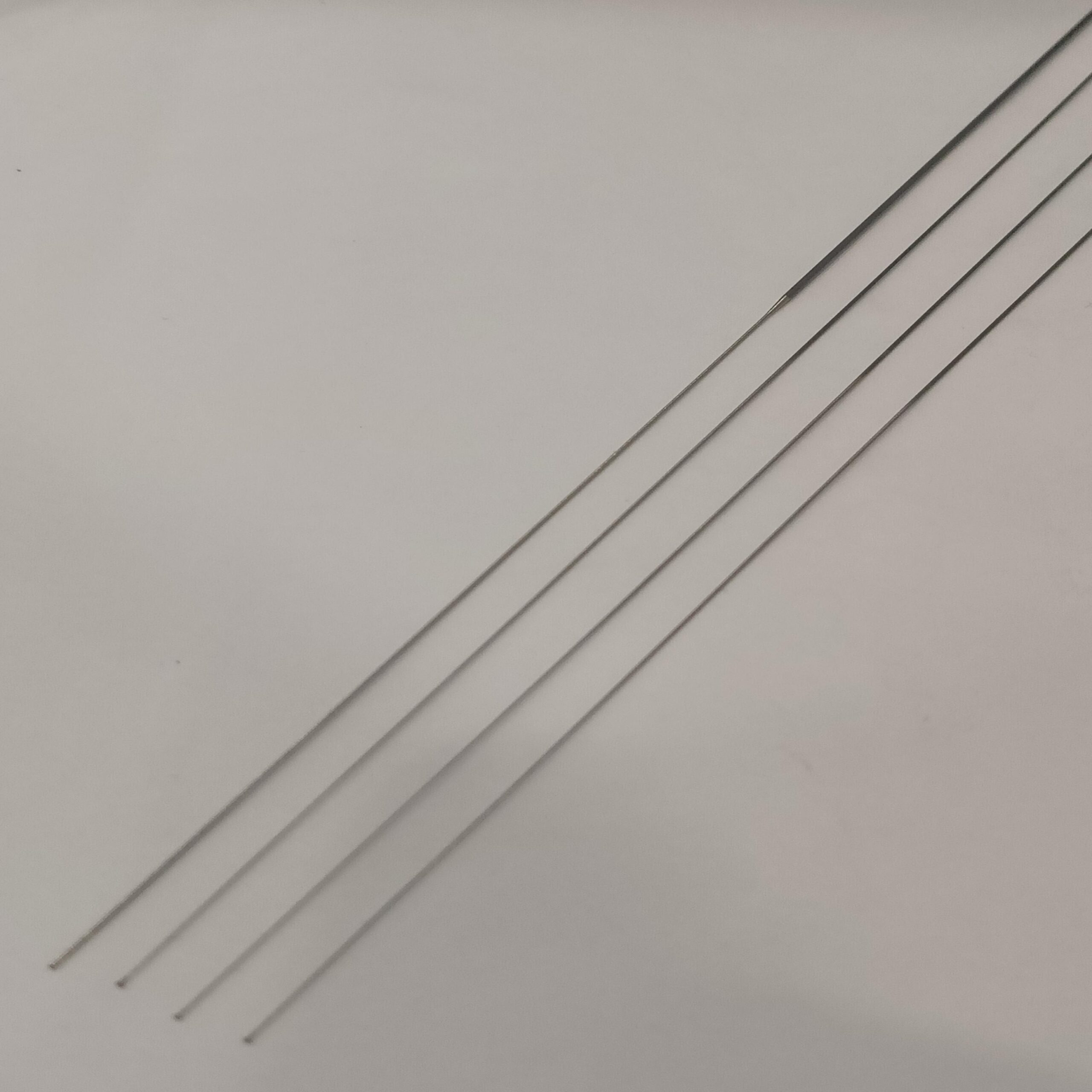

Premium Shape Memory Nitinol Wire for Medical Grinding Applications

Our shape memory nitinol wire engineered for medical grinding delivers outstanding performance tailored for advanced healthcare devices. Combining smart alloy properties with precision manufacturing, this wire meets the highest medical standards for reliability and biocompatibility.

High-Quality Material Composition

Crafted from a near-equiatomic nickel-titanium alloy (Nitinol), this shape memory nitinol wire exhibits exceptional superelasticity and shape recovery capabilities. The unique alloy composition enables the wire to return automatically to its original shape after exposure to heat or mechanical stress, making it ideal for medical devices requiring repeated flexing or precise movement.

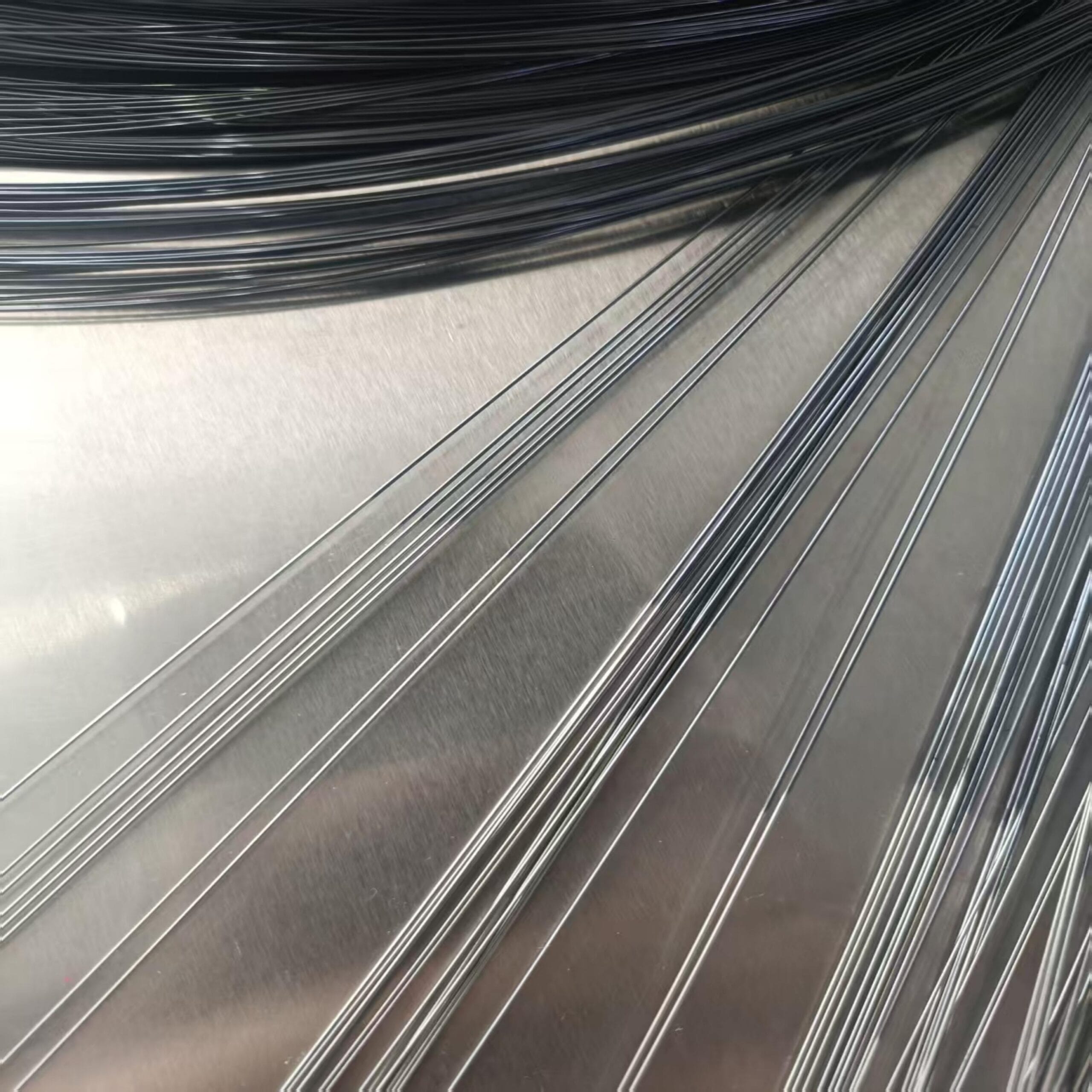

Superior Medical-Grade Surface Finish

We employ a specialized medical grinding process to provide a smooth, uniform surface finish on the shape memory nitinol wire. This polish reduces friction during insertion and operation, while resisting corrosion and bacterial adhesion—critical for maintaining sterile conditions. The surface quality aligns with ISO 13485 standards, ensuring safe use in sensitive biological environments.

Precise Diameter Range and Tolerances

Available in diameters ranging from 0.1 mm to 2.0 mm, this shape memory nitinol wire supports a broad spectrum of applications—from minimally invasive surgical tools to larger implantable devices. Custom sizes are also available, with tight manufacturing tolerances of ±0.01 mm guaranteeing consistent performance under high stress.

Versatile Medical Applications

Orthodontic Archwires: Gentle, effective tooth alignment via shape memory action.

Cardiovascular Stents: Superelastic properties enable compact, catheter-based delivery.

Surgical Guidewires: Flexible design navigates complex anatomy without kinking.

Bone Fixation Devices: High fatigue resistance supports long-term implants.

Endoscopic Instruments: Smooth surface minimizes tissue trauma during procedures.

Why Choose Our Shape Memory Nitinol Wire?

Uncompromising Quality Control

Manufactured using vacuum furnace melting to eliminate impurities, each batch undergoes rigorous testing for phase transformation temperature, tensile strength, and durability across millions of cycles.

Full Medical Compliance

Our wire complies fully with ASTM F2063 and FDA regulations for implantable materials. Comprehensive traceability documentation supports your regulatory submissions with confidence.

Customizable Properties

Engineering teams tailor transformation temperatures (from -20°C to 100°C) and mechanical attributes to precisely fit your medical device requirements.

Efficient Lead Times

State-of-the-art automated grinding combined with in-house testing ensures rapid production, with most orders shipping within 10 business days.

Cost-Effective Performance

Optimized manufacturing reduces waste and prolongs fatigue life (exceeding 10 million cycles), minimizing replacement costs for reusable instruments.

Expert Technical Support

We provide detailed guidance on wire selection, forming techniques, and sterilization methods including autoclave, ethylene oxide (ETO), and gamma radiation.

This shape memory nitinol wire is engineered to solve complex challenges in medical device design, offering unmatched flexibility, strength, and biocompatibility. Its advanced shape memory capabilities simplify implantation while ensuring patient safety with a medical-grade surface finish. Contact us today to discover how this premium material can elevate your next-generation medical products.

Reviews

There are no reviews yet.