Shape Memory Alloy Nitinol Wire for Urology Devices

Advanced Material for Precise Medical Applications

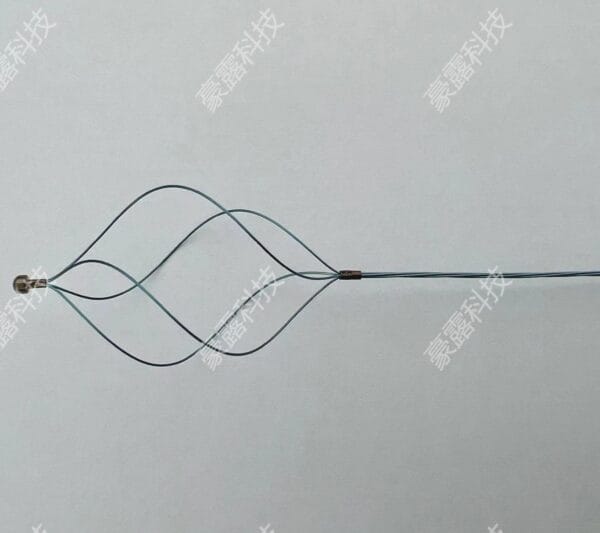

Our nickel-titanium alloy (nitinol) wire merges superelastic properties with excellent tissue compatibility. This smart material instantly regains its preset shape post-stress, delivering reliable performance in flexible, precision-driven minimally invasive urology interventions.

Refined Surface Treatment for Patient Safety

The shape memory alloy nitinol wire is treated with advanced electropolishing and acid cleansing techniques to ensure a clean, low-friction surface. These processes effectively remove microscopic contaminants while strengthening the wire’s corrosion resistance. The result is a highly polished, biocompatible surface that promotes safer, smoother performance in sensitive urology procedures.

Wide Diameter Range for Versatility

We offer nickel titanium wire in diameters ranging from 0.1 mm to 5.0 mm. Thinner wires are perfect for applications like stent delivery, while thicker options support guidewires and catheter systems.

Common Applications in Urology

Our superelastic wire plays a key role in multiple urology tools:

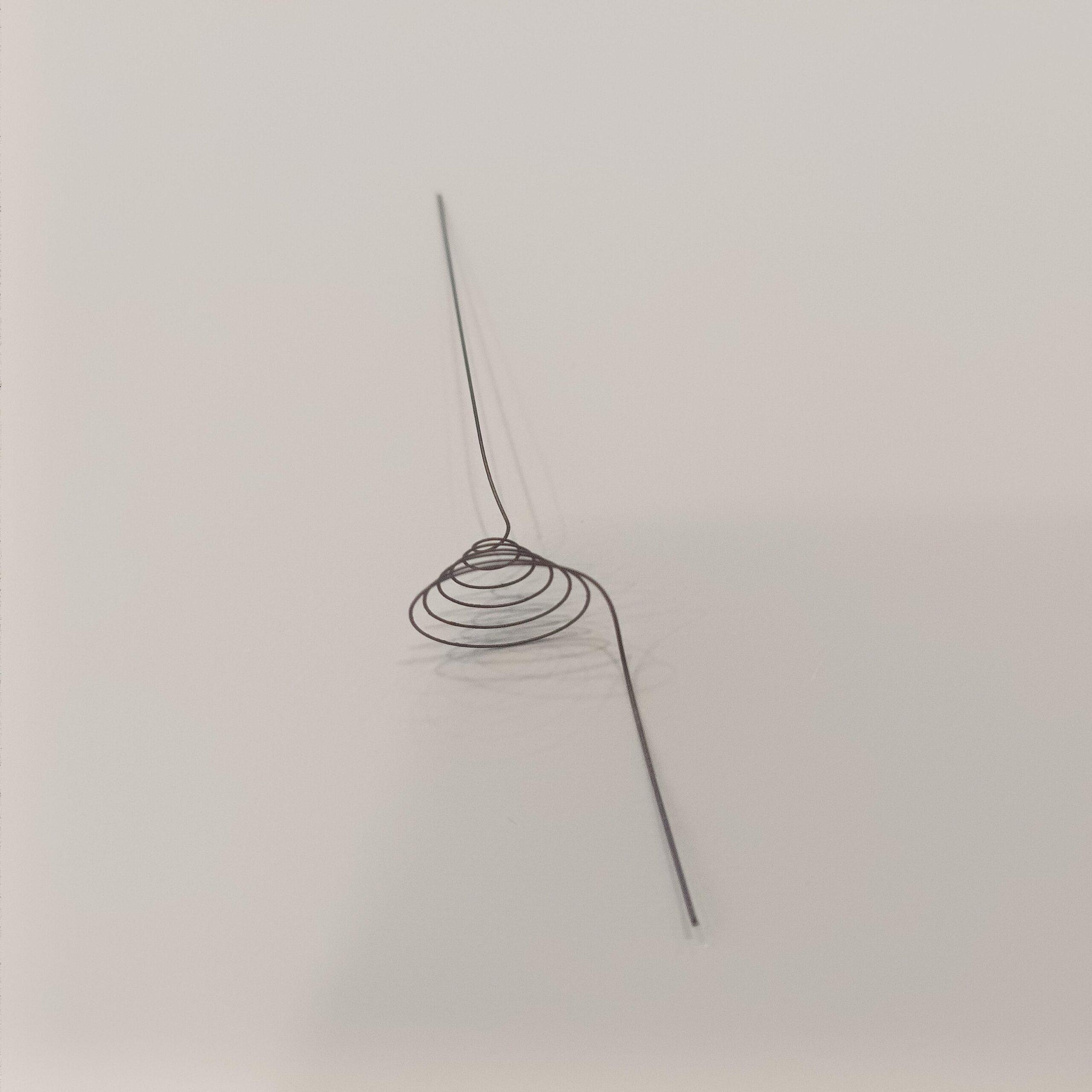

Ureteral stents – Easily conform to anatomical pathways.

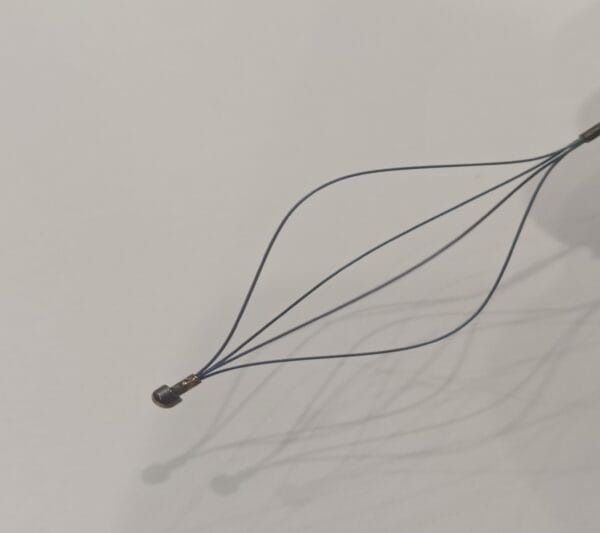

Stone retrieval baskets – Shape memory enables controlled expansion and retraction.

Flexible catheters – Withstand repeated bending without permanent damage.

Biopsy tools – Provide strength and consistency during tissue collection.

This material is also widely used in cardiology, orthodontics, and robotic-assisted devices.

Why Choose Our Shape Memory Alloy Nitinol Wire

1. Precision Manufacturing

Each nitinol wire is engineered to exact tolerances, ensuring reliable shape memory and superelastic behavior.

2. Superior Patient Comfort

Its smooth finish and flexibility help reduce tissue trauma and postoperative discomfort.

3. Exceptional Durability

The wire resists fatigue and corrosion, enabling long-term use without performance loss.

4. Simplified Surgical Use

Thanks to its memory effect, the wire enables automatic deployment, saving time during complex procedures.

5. Regulatory Compliance

Every wire meets ISO 13485 and FDA standards, undergoing comprehensive testing to confirm its strength, purity, and compatibility with biological tissues.

6. Custom Solutions Available

We tailor transition temperatures, tensile strength, and dimensions to meet specific device needs.

7. Eco-Friendly Production

Our manufacturing process minimizes waste and uses recyclable materials to reduce environmental impact.

Conclusion

Combining smart material behavior with exceptional strength and safety, our shape memory alloy nitinol wire supports next-generation urology devices. With its flexible diameter options, smooth surface, and regulatory approval, it’s the preferred choice for hospitals and medical device manufacturers worldwide.

Reviews

There are no reviews yet.