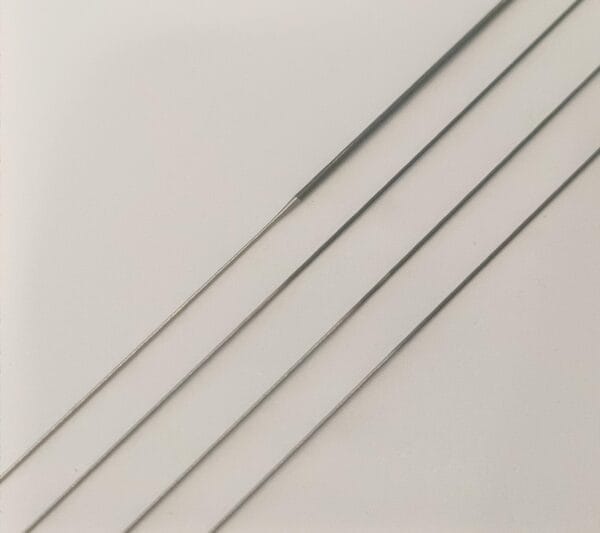

PTFE Coated Nitinol Wire for Precision Applications

Engineered Material Performance

Our PTFE coated nitinol wire combines the exceptional flexibility of nickel-titanium alloy (Nitinol) with a durable, high-performance PTFE (polytetrafluoroethylene) coating. Nitinol provides exceptional shape memory and superelastic properties, making it ideal for demanding applications. A non-stick PTFE layer provides a low-friction surface. Its stability enhances durability and maintains consistent performance.Fully compliant with ASTM F2063, this wire is engineered for critical use in medical, aerospace, and high-tech industrial sectors.

Optimized Surface Finish with PTFE

The PTFE coating ensures a smooth, uniform finish that reduces friction and resists chemical adhesion. This results in enhanced corrosion resistance and prolonged fatigue life, especially in wet, abrasive, or high-heat environments. The coating process maintains the structural integrity and flexibility of the Nitinol core, ensuring consistent, long-term performance.

Wide Diameter Range for Customization

We supply PTFE coated nitinol wires in diameters ranging from 0.005 inches (0.127 mm) to 0.060 inches (1.524 mm). This flexibility allows precise adaptation to specific project requirements—from micro-scale medical components to high-load industrial tools.

Application Versatility

Medical Devices: Ideal for guidewires, stents, surgical tools, and orthodontic archwires where biocompatibility and superelasticity are essential.

Industrial Grinding: The PTFE surface reduces heat generation and debris buildup during abrasive processes.

Aerospace Components: Delivers stable performance in extreme temperatures, commonly used in actuators and sensors.

Electronics: PTFE insulation shields nitinol wires in precision circuits and compact connectors, ensuring reliable electrical performance.

Oil & Gas: Corrosion-resistant in downhole and offshore environments.

Why Choose Our PTFE Coated Nitinol Wire?

Advanced Material Compatibility

This unique combination of nitinol’s flexibility and PTFE’s durability provides a wire that resists wear, corrosion, and mechanical fatigue. The shape memory effect enables the wire to return to its original shape after deformation, while the coating safeguards against damage.

Precision Engineering Standards

Our cutting-edge coating technology and rigorous production controls ensure uniform layer thickness and precise wire measurements.Every spool undergoes rigorous testing to comply with ASTM F2063 standards, ensuring dependable quality.

Each spool is tested against ASTM F2063 standards for consistency and reliability.

Biocompatibility and Safety

PTFE’s biocompatibility and toxin-free composition make it ideal for surgical tools and human implants. This material complies with ISO 10993 for medical device safety.Its non-reactive nature ensures stability in chemically aggressive environments.

Energy Efficiency and Longevity

Low-friction properties mean reduced wear and lower energy demands in dynamic systems. The fatigue resistance of nitinol paired with the chemical durability of PTFE helps minimize the frequency of replacements and lowers maintenance expenses.

Customized Solutions for Your Requirements

We offer flexible customization options including different wire diameters, coating thickness levels, and spool sizes. Our knowledgeable team is available to guide you in choosing the best specifications to suit your unique project needs.

Reliable Worldwide Supply

Supported by ISO-certified production processes and thorough quality control inspections, we guarantee high-quality products from manufacturing to shipment. Our adaptable logistics and quick delivery services ensure your deadlines are met efficiently.

Reviews

There are no reviews yet.