Nitinol Mandrel & Wire: Superior Flexibility for Advanced Applications

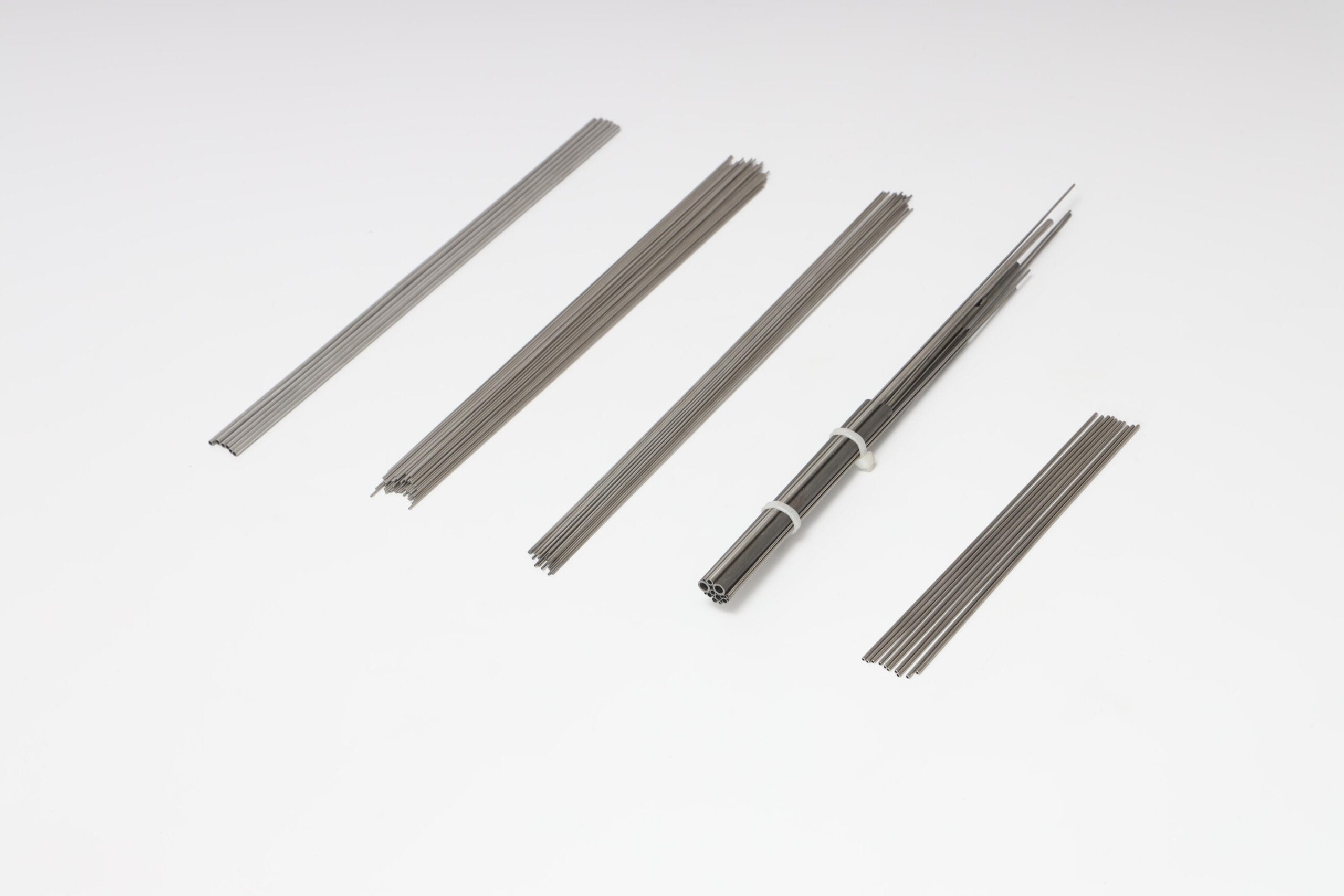

Our factory specializes in manufacturing high-performance nitinol mandrels and wire. We provide robust, reliable solutions for industries demanding precision and advanced material properties.

Understanding Nitinol Material

Nitinol is a unique metal alloy, blending nickel and titanium. This special composition gives the material two remarkable traits: shape memory and superelasticity.

A nitinol component can return to its original shape when heated. It can also bend and flex far beyond ordinary metals without staying deformed. These qualities make nitinol mandrels and wire ideal for challenging environments.

Primary Uses of Nitinol Mandrel

So, what is the purpose of a nitinol mandrel? This tool acts as an internal support spine. It is essential for bending delicate tubing and creating precise coils.

Using a nitinol mandrel prevents kinks and collapses in your workpiece. Its superior flexibility allows for tight, complex bends that rigid tools cannot achieve. This makes the nitinol mandrel a top choice for manufacturing medical catheters, aerospace tubing, and specialized springs.

Nitinol in Medical & Industrial Applications

What is nitinol mainly used for? The answer spans critical fields.

Medical Devices: Nitinol wire forms the core of guidewires and stents. Its superelasticity lets it navigate the human body safely. Stents made from nitinol can compress, travel through vessels, and then expand to their intended shape with body heat.

Aerospace & Industry: The alloy is perfect for tight-tolerance couplings, actuators, and robotic components. Its durability and fatigue resistance ensure long-term performance.

Machining Nitinol: Our Expertise

Can Nitinol be machined? Absolutely. However, machining nitinol presents challenges. It is a tough, sticky material that work-hardens rapidly.

Our factory overcomes these problems with nitinol. We use specialized techniques, advanced tooling, and controlled processes. We expertly machine nitinol mandrels and wire to your exact specifications, delivering a ready-to-use, high-quality product.

Addressing Nitinol Problems

We understand the potential problems with nitinol. Our process ensures these are managed effectively.

Biocompatibility: For medical applications, we provide materials with a stable surface oxide layer, isolating nickel and ensuring safety.

Cost & Machining: While raw material costs are high, our efficient production provides excellent value. We handle the difficult machining, so you don’t have to.

Heat Sensitivity: We meticulously control all thermal processes to preserve the alloy’s critical transformation temperatures and mechanical properties.

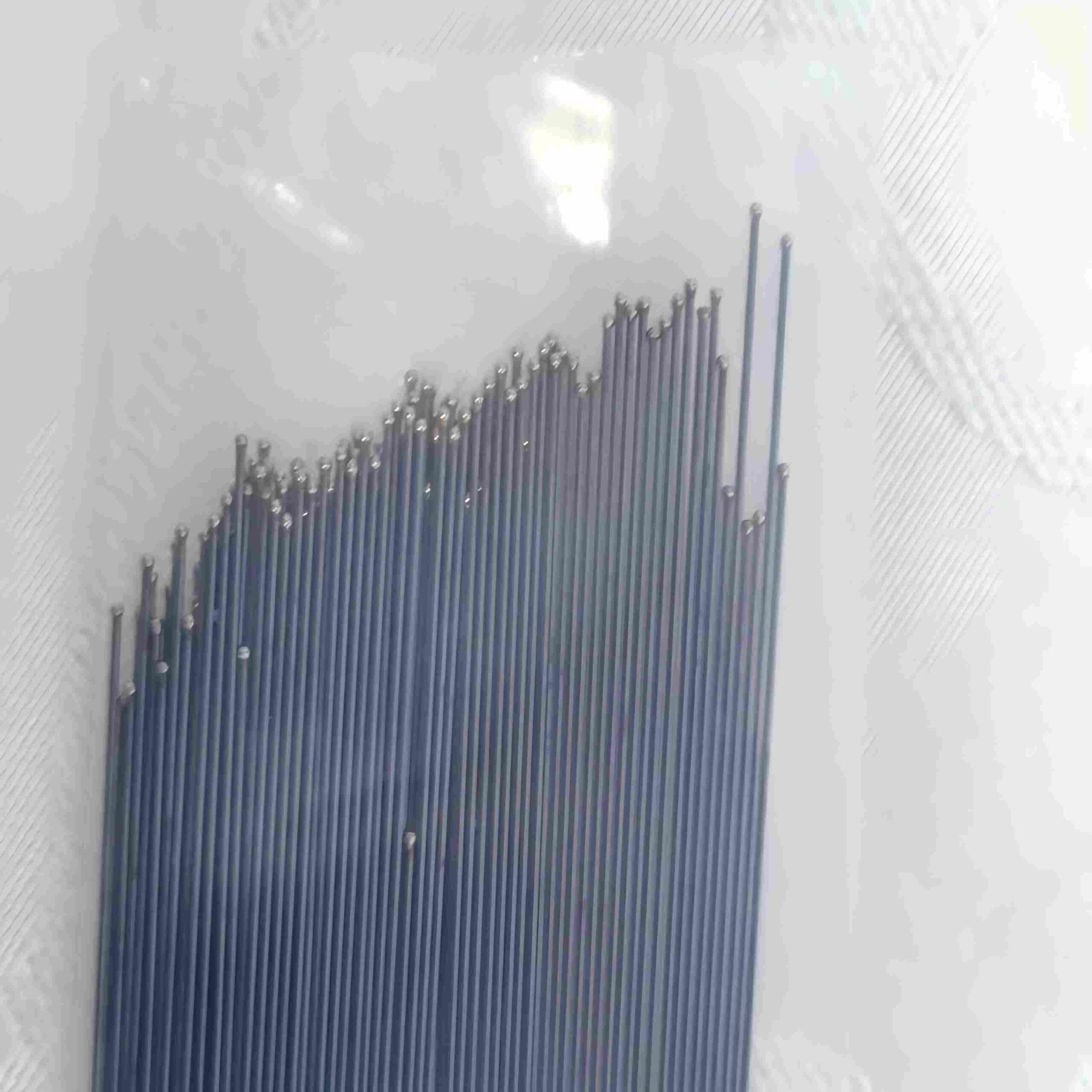

Our Product Specifications: Diameter Range

We offer a comprehensive diameter range to meet diverse project needs.

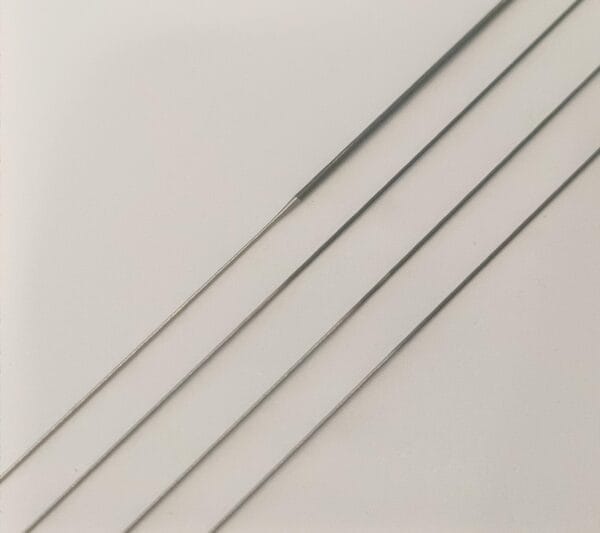

Nitinol Wire: 0.05 mm up to 2.0 mm

Nitinol Mandrels: 0.5 mm up to 10 mm

We guarantee consistent quality, from material sourcing to final inspection. Our products deliver the performance and reliability your advanced applications require.

Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolusa.com

Mid East Region:getnitinol.com

Nitinol Wire – Superelastic and shape memory wires for medical and industrial use

Nitinol Tube – Precision tubing for minimally invasive devices

Nitinol Rope – High-flexibility nickel titanium braided strands

Nitinol Guide Wire – Navigate complex anatomies with kink-resistant precision

Reviews

There are no reviews yet.