Orthopedic Implant Nitinol Sheet Metal – High-Performance Material for Medical Innovation

Introducing Nitinol Sheet Metal for Orthopedic Implants

Our nitinol sheet metal, a premium nickel-titanium alloy, is engineered for orthopedic implants requiring flexibility, strength, and biocompatibility. This advanced material supports durable and adaptive medical devices that meet the highest industry standards.

Premium Material: Nickel-Titanium Alloy (Nitinol)

Our nitinol sheet metal is engineered to exhibit outstanding superelastic and shape memory effects, allowing implants to bend and return to their original shape under stress. This flexibility is essential for orthopedic devices that must accommodate natural body movements. Certified to meet ASTM F2063 standards, the alloy boasts corrosion resistance, fatigue endurance, and stability across extreme temperatures—ensuring long-lasting implant functionality and patient safety.

Precision Surface Finishes for Medical Safety

Every nitinol sheet receives careful finishing to comply with rigorous medical industry standards:

Mirror Polishing: Minimizes friction and tissue irritation.

Electropolishing: Enhances corrosion resistance by removing impurities.

Pickling: Produces a clean oxide-free surface for optimal coating adhesion.

These surface treatments enhance biocompatibility while minimizing bacterial growth, promoting improved bonding with both bone and surrounding soft tissues.

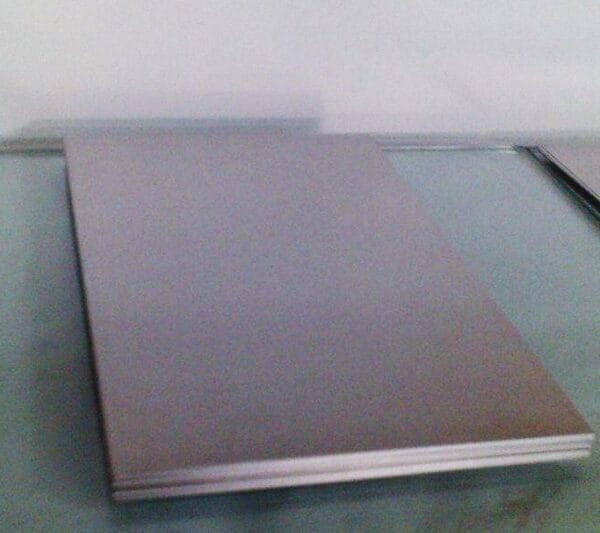

Versatile Thickness and Size Options

Available in thicknesses from 0.1 mm up to 5.0 mm, our nitinol sheet metal comes in standard dimensions such as 100 x 300 mm and 200 x 500 mm. Custom sizes and shapes are easily fabricated to meet specialized orthopedic implant designs. Thin sheets are ideal for bone plates and spinal devices, while thicker sheets provide robust support for load-bearing implants like hip and joint replacements.

Key Applications in Orthopedics

Our nitinol sheet metal serves a crucial function in:

Bone Plates and Screws: Flexibility to support healing bones without fracture risk.

Spinal Implants: Elasticity that reduces stress on vertebrae during movement.

Joint Replacement Components: Durable enough to handle repetitive motions.

Trauma Fixation Devices: Lightweight strength for fracture stabilization.

Dental Implants: Secure and comfortable support for artificial teeth.

Why Choose Our Nitinol Sheet Metal?

Medical-Grade Quality: Produced in ISO 13485-certified facilities, ensuring rigorous testing of composition and biocompatibility.

Customization: Thickness, size, and surface finish tailored to your project specifications.

Fast Delivery: Prototypes and bulk orders shipped within 2-4 weeks.

Technical Expertise: Experienced engineers provide guidance on material selection and regulatory compliance.

Competitive Pricing: Efficient processes reduce costs without sacrificing quality.

Global Standards Compliance: Meets EU MDR, FDA, and other international orthopedic implant regulations.

Transforming Orthopedic Care with Nitinol Sheet Metal

Nitinol sheet metal addresses critical challenges in implant design by combining flexibility and strength with superior biocompatibility. Its unique properties help prevent device failure, reduce rejection risks, and promote faster patient recovery. Whether stabilizing fractures or enabling dynamic spinal systems, nitinol sheet metal stands at the forefront of orthopedic innovation.

Partner with a Leading Nitinol Supplier

With over 20 years in metallurgy, our advanced rolling and heat treatment processes guarantee consistent, high-quality nitinol sheet metal products. Collaborate with us to elevate your orthopedic implant projects with cutting-edge materials.

Request a Quote Today

Contact us with your specifications for pricing, samples, or technical data—delivered within 24 hours. Choose nitinol sheet metal: the smart solution for next-generation orthopedic implants.

Reviews

There are no reviews yet.