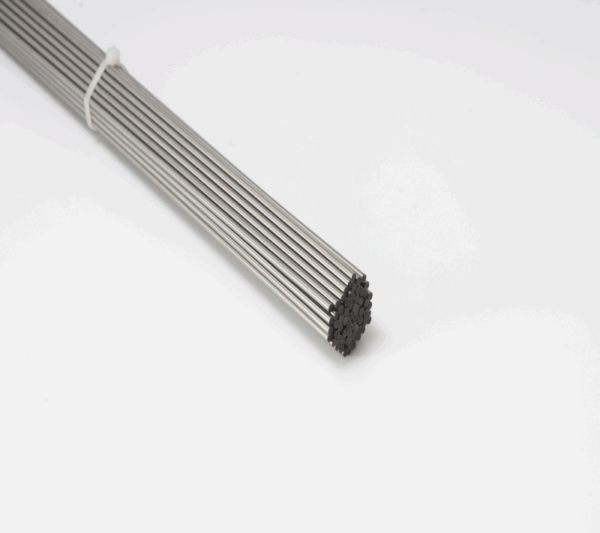

Nitinol Wire Shape Setting for Superelastic Tube Components

Unlock the full potential of precision-engineered systems with our Nitinol wire shape setting tube components—engineered for demanding environments across medical, aerospace, and industrial sectors. Crafted from premium nickel-titanium alloy, these shape-set superelastic tubes deliver consistent performance, even under extreme conditions.

Material Excellence

Our components utilize high-grade Nitinol alloy known for its superelasticity, biocompatibility, and corrosion resistance. Capable of bending and returning to their original shape under significant stress, these tubes outperform traditional metals in applications requiring flexibility, fatigue resistance, and durability.

Advanced Surface Finishing

We offer customizable surface treatments tailored to specific applications:

Electropolished surfaces: Ideal for medical and surgical tools, offering ultra-smooth, contaminant-free finishes.

Mechanically polished finishes: Designed for industrial systems that demand toughness and wear resistance.

Etched textures: Enhance bonding for coatings or adhesives.

Wide Diameter Range for Versatile Design

Our Nitinol tubes are available in diameters ranging from 0.1 mm to 10 mm, making them suitable for everything from micro-scale medical instruments to large industrial assemblies. Custom dimensions are available to precisely align with your specific project requirements.

Targeted Applications

Medical Devices: Perfect for stents, catheters, orthodontic wires, and minimally invasive instruments due to their biocompatibility and flexibility.

Aerospace Systems: Used in actuators and vibration-damping systems requiring lightweight, fatigue-resistant solutions.

Industrial Automation: Applied in robotics, energy-efficient actuators, and high-performance fluid control systems.

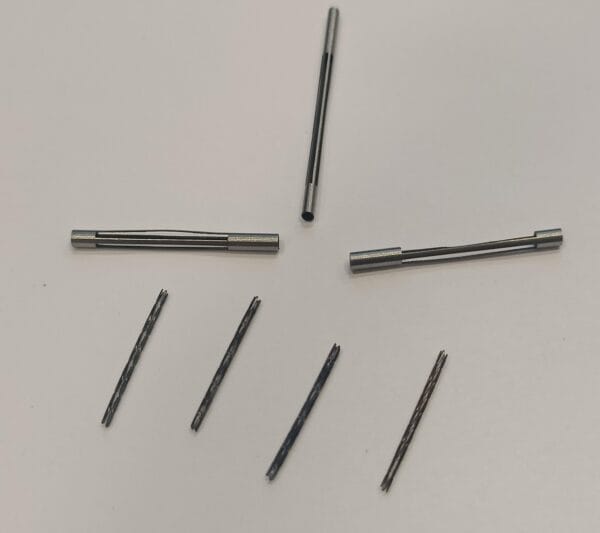

Why Choose Our Nitinol Tube Components?

Precision Shape Setting: Our proprietary nitinol wire shape setting process ensures tight tolerances and shape memory repeatability.

Tailored Engineering: From diameter and finish to thermal response, every component is engineered for your project.

Certified Quality: Manufactured under ISO 13485 and ASTM F2063 standards, with full traceability and performance validation.

Technical Support: Our engineering team collaborates from concept to delivery, solving complex challenges with customized strategies.

Fast Turnaround: Streamlined production ensures you meet deadlines without compromising on quality.

Key Advantages

Superelastic Recovery: Up to 8% strain recovery—far exceeding stainless steel.

Durability: Exceptional resistance to fatigue, corrosion, and temperatures from -50°C to 150°C.

Biocompatibility: Safe for long-term implantation and interaction with human tissue.

Energy Efficiency: Reduce power consumption in responsive components like actuators and sensors.

Whether you’re developing next-generation medical devices, aerospace technologies, or industrial automation, our Nitinol wire shape setting tube components offer the durability, precision, and flexibility your application demands.

Reach out to us today to discover customized solutions that turn your design concepts into reality.

Reviews

There are no reviews yet.