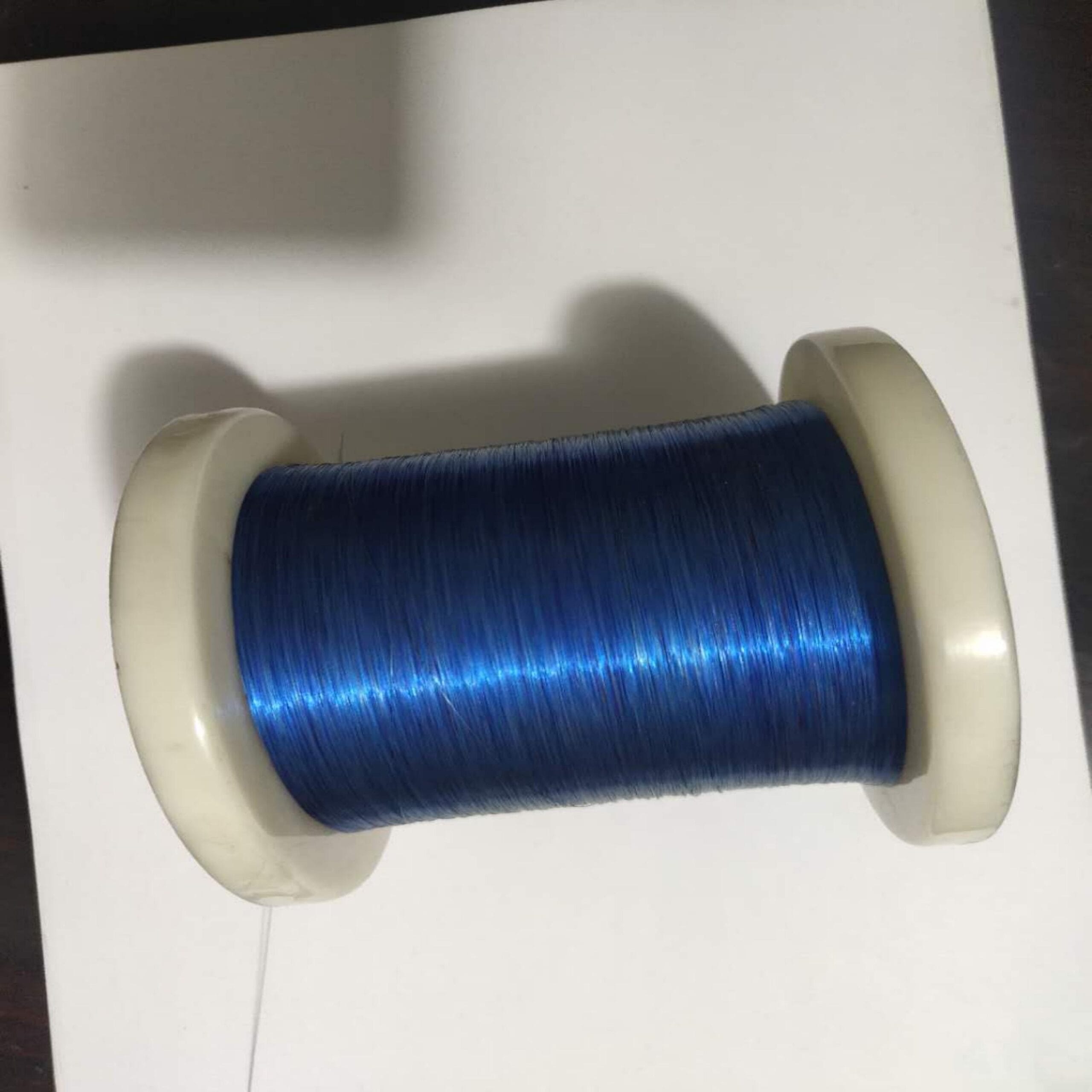

0.025mm Neurovascular Nitinol Microfilament

Trusted by Global Medical Innovators | Precision by Top Nitinol Wire Manufacturers

As premier Nitinol wire manufacturers, we are dedicated to producing ultra-fine, high-performance wire solutions for critical medical applications. Our 0.025mm Neurovascular Nitinol Microfilament is specifically engineered to meet the complex requirements of modern neurovascular interventions. It combines outstanding flexibility, fatigue resistance, and biocompatibility. Therefore, this ultra-thin Nitinol wire becomes the ideal choice for intricate, life-saving devices that demand the highest reliability.

Material Excellence

We utilize a premium Nickel-Titanium alloy composed of 50.8% nickel and 49.2% titanium, which offers superior shape memory and superelastic characteristics. Moreover, we meticulously verify each batch of our alloy for purity and uniformity, ensuring it meets stringent international benchmarks like ASTM F2063.

Superior Surface Finish

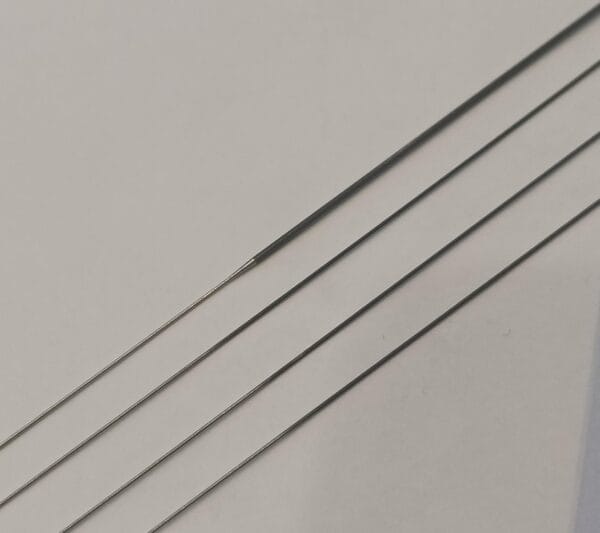

Our microfilament undergoes high-precision electropolishing, creating a flawless, mirror-like surface. This process reduces surface friction, minimizes thrombogenicity, and enhances endothelial compatibility—critical factors in neurovascular applications.

Diameter Flexibility

The product features a standard 0.025mm diameter, making it ideal for ultra-miniature neurovascular devices. Additionally, we offer custom diameters ranging from 0.015mm to 0.5mm to meet your unique design needs.

Key Medical Applications

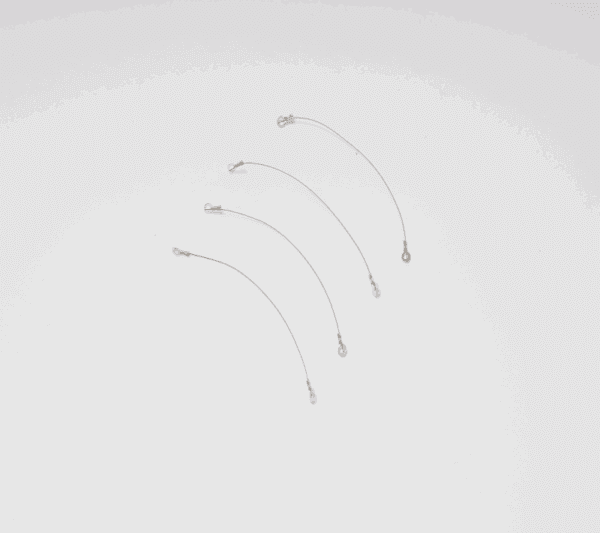

Embolic Coils: Precisely place coils during aneurysm treatments

Stent Delivery Systems: Facilitate flexibility and deployment in narrow, curved vasculature

Guidewires: Enhance trackability through tortuous anatomy

Neurovascular Catheters: Improve torque transmission and pushability

Minimally Invasive Implants: Maintain mechanical integrity over extended cycles

Why Partner with Our Nitinol Wire Manufacturing Team?

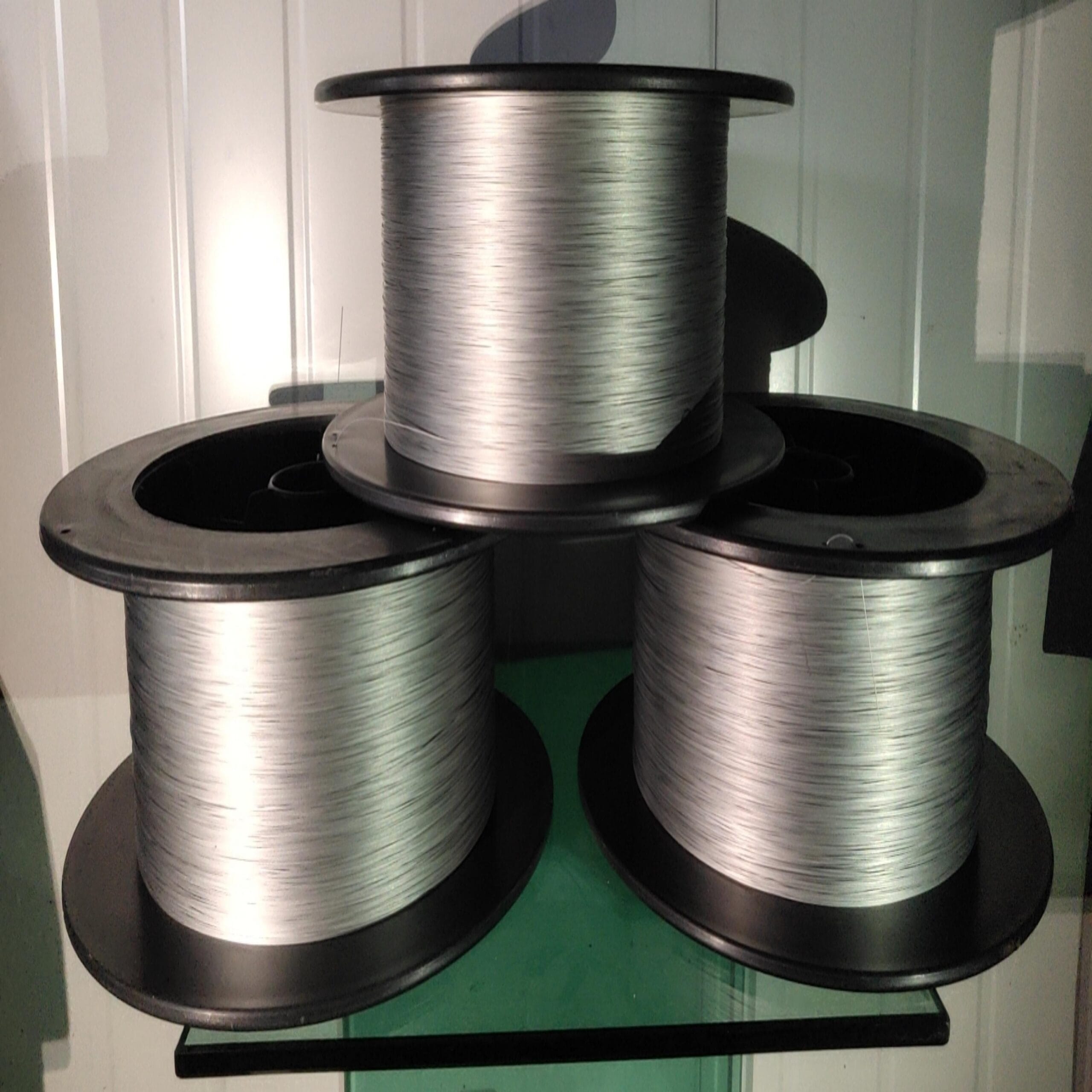

Proven Expertise in Nitinol Wire Production

With over 20 years of experience, we excel as Nitinol wire manufacturers, utilizing advanced processes—melting, hot working, and cold drawing—to produce wires with uniform grain structure and predictable mechanical performance.Rigid Quality Control

We perform mechanical testing, transition temperature analysis, and surface integrity inspections on every batch. As a result, all products comply with ISO 13485 and ASTM standards for medical use.Customized Engineering Support

Our team adapts parameters such as transformation temperature (Af) and elongation according to your device specifications. Thus, every microfilament functions flawlessly under real-world clinical conditions.Accelerated Delivery

We deliver samples within 7 days and complete full-scale production in 4–6 weeks. Thanks to efficient in-house testing and automation, we ensure fast, reliable supply without compromising quality.End-to-End Technical Guidance

From prototyping to mass production, our engineers provide expert support in laser cutting, heat treatment, and mechanical processing. Therefore, we help you navigate challenges related to Nitinol manufacturing.

Innovate with Confidence

Neurovascular procedures require materials that balance precision with strength. Our 0.025mm Nitinol Microfilament delivers optimal thinness, kink resistance, and cyclic fatigue durability. Consequently, you can trust the expertise of established Nitinol wire manufacturers to bring your next-generation medical devices to life.

Contact us today for technical datasheets, compliance certificates, or a quote. Together, we can advance the future of neurovascular care.

Reviews

There are no reviews yet.