Nitinol Tubes Segment for High-Performance Medical Applications

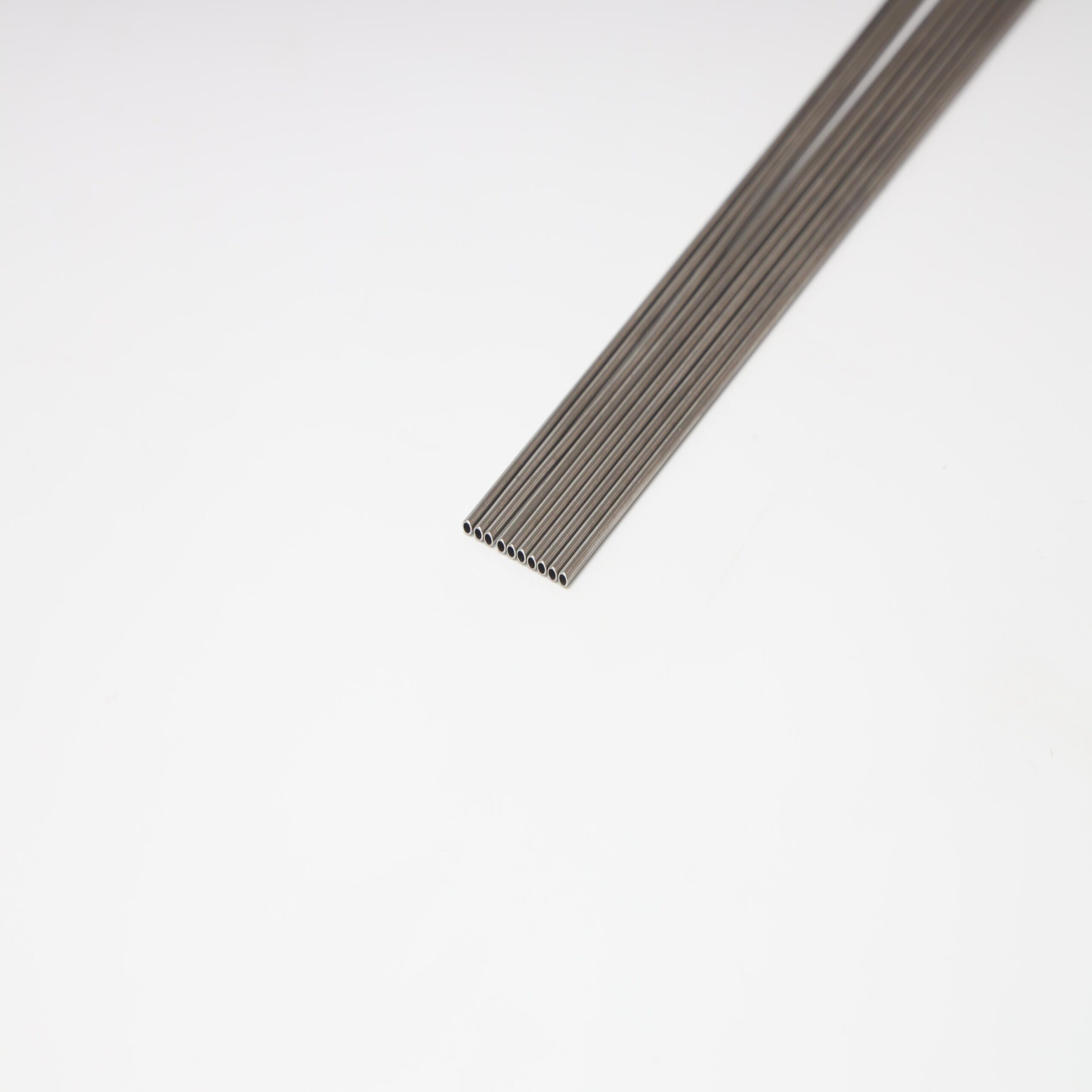

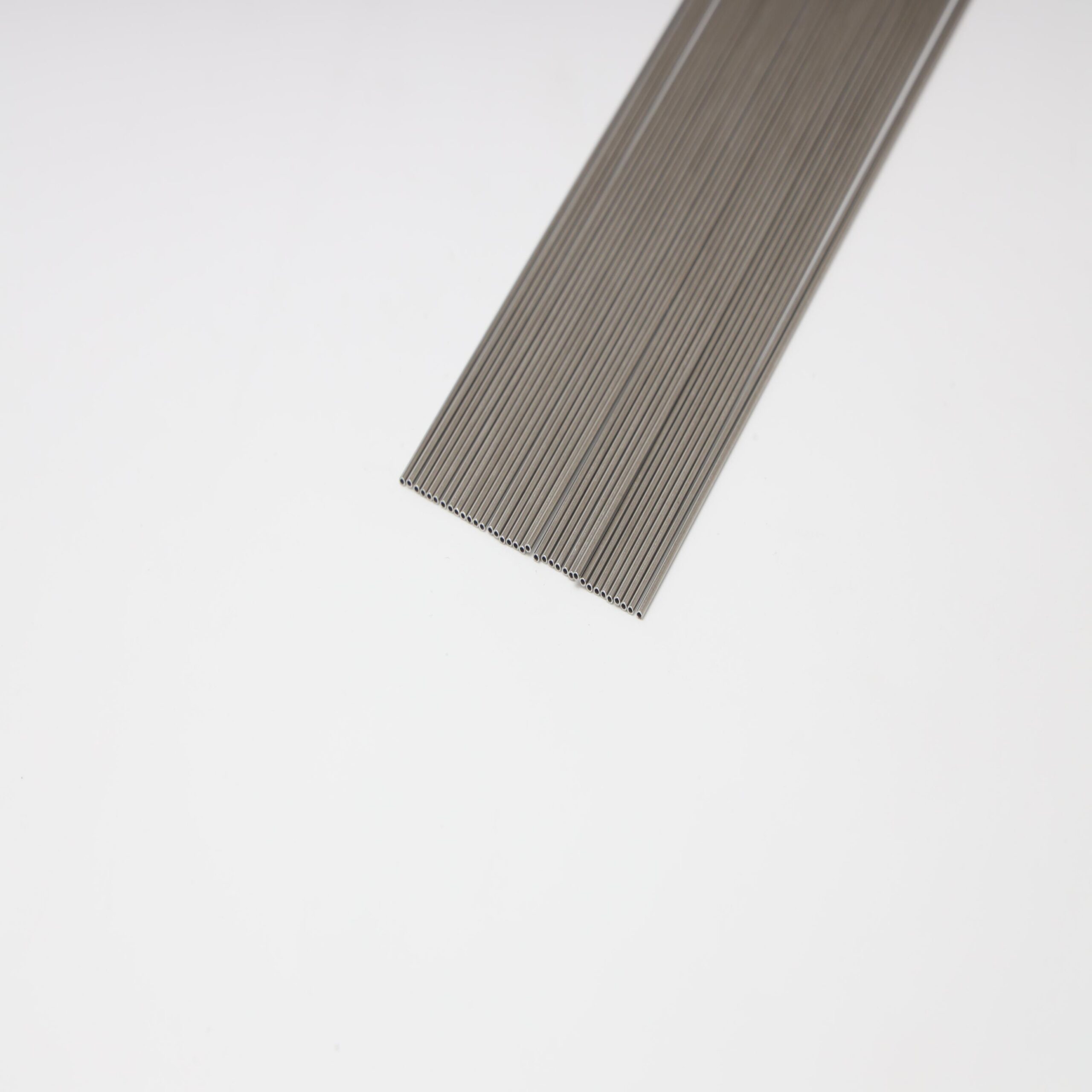

Introduction to the Nitinol Tubes Segment

Our nitinol tubes segment delivers unmatched performance for critical medical applications. Manufactured using high-quality nickel-titanium alloy, these tubes provide exceptional superelasticity, shape memory, and excellent biocompatibility.As a leading manufacturer in this field, we ensure every tube meets the exacting demands of modern healthcare.

Premium Material for Medical Reliability

This segment utilizes certified nickel-titanium alloys that ensure consistent material behavior under mechanical stress. The tubes’ superelastic recovery and shape retention make them ideal for minimally invasive procedures and implantable devices. Designed for long-term use, the material’s biocompatibility helps minimize adverse patient reactions.

Superior Surface Finish

We apply advanced electropolishing to each tube, resulting in ultra-smooth surfaces that reduce friction during insertion. This process enhances device longevity while minimizing tissue irritation, infection risks, and performance loss caused by surface irregularities.

Wide Range of Dimensions

Our nitinol tubing offers:

Available outer diameters span from 0.010″ up to 0.500″ (0.25 mm to 12.7 mm).

Wall thicknesses from 0.001″ to 0.050″ (0.025 mm to 1.27 mm)

Tight tolerances of ±0.0005″

This versatility empowers engineers to design innovative, minimally invasive devices with precision fit.

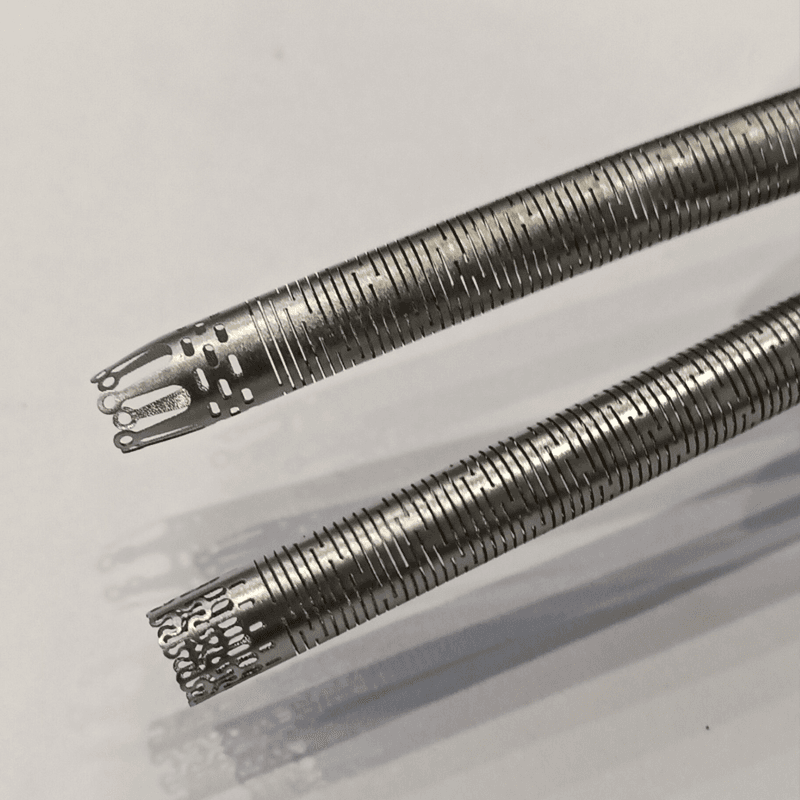

Key Applications of Nitinol Tubing

Our tubing is essential in:

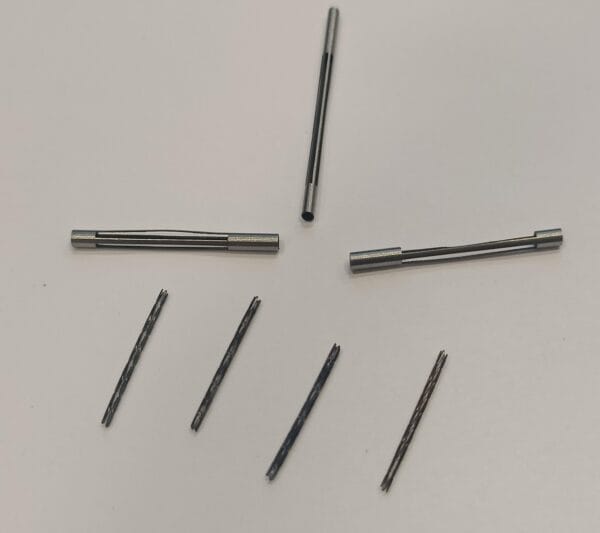

Cardiovascular stents, catheters, and guidewires

Neurovascular aneurysm treatment systems

Orthopedic fixation tools

Robotic surgery and endoscopic instruments

Drug delivery systems

MRI compatibility and kink resistance further enhance safety and functionality in complex procedures.

Why Partner with Us for Nitinol Tube Solutions

Proven Medical Alloy Expertise

We specialize exclusively in manufacturing nitinol tubing, backed by over 20 years of biomedical engineering experience.

Stringent Quality Standards

Each batch undergoes rigorous testing for phase transformation, tensile strength, and fatigue resistance. All manufacturing processes conform to ISO 13485 and ASTM F2063 standards.

Custom Engineering & Rapid Delivery

We offer tailored solutions, including laser cutting, coiling, and cleanroom packaging. Emergency orders ship within 72 hours.

Sustainability Commitment

We recycle 98% of production waste and employ energy-efficient processes that minimize environmental impact without sacrificing quality.

Conclusion

Advancements in medical technology heavily rely on innovations within the nitinol tubes segment. With proven reliability, precision, and full customization, our tubing solutions support the future of patient care.

Contact us today to request samples or discuss your next medical innovation.

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolalloy.com

Mid East Region:getnitinol.com

Reviews

There are no reviews yet.