Nitinol Tube Expansion: Corrosion-Resistant Tubing for Demanding Applications

High-Performance Alloy Enables Reliable Nitinol Tube Expansion

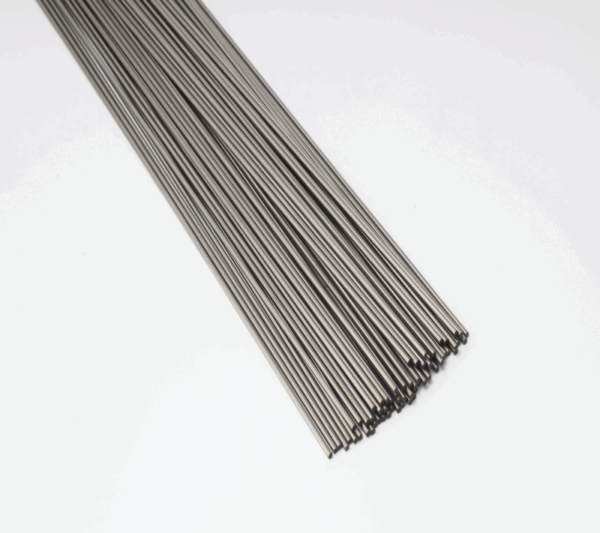

Nitinol tube expansion plays a vital role in advanced engineering where both flexibility and durability are critical under extreme conditions. Crafted from a high-grade nickel-titanium alloy (comprising 55% nickel and 45% titanium), our tubing delivers excellent shape memory, superior elasticity, and outstanding resistance to corrosion. These properties make it highly suitable for use in medical devices, aerospace systems, and industrial applications that encounter mechanical strain or fluctuating temperatures.

Electropolished Finish for Consistent Performance

Each tube undergoes electropolishing to remove impurities and create an ultra-smooth surface. This finish not only improves biocompatibility but also supports stable nitinol tube expansion under repeated cycles. Optional oxide layers or coatings can be added for enhanced performance in specialized environments.

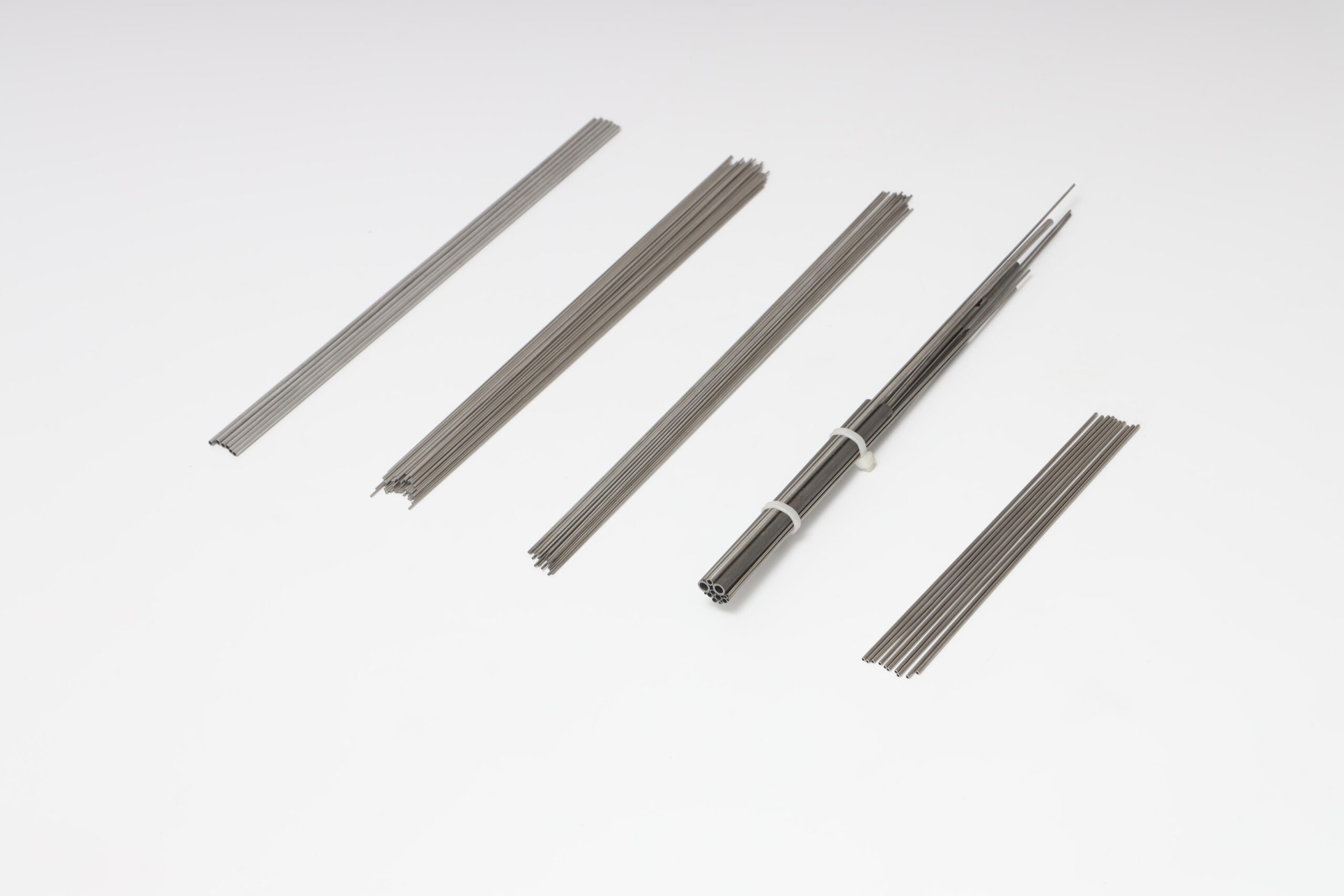

Wide Size Range with Tight Tolerances

We offer Nitinol tubing in outer diameters ranging from 0.1 mm to 12 mm and wall thicknesses between 0.05 mm and 2 mm. With tolerances down to ±0.001 mm, our tubes meet custom specifications while maintaining expansion reliability, flexibility, and radial strength.

Versatile Applications Across Industries

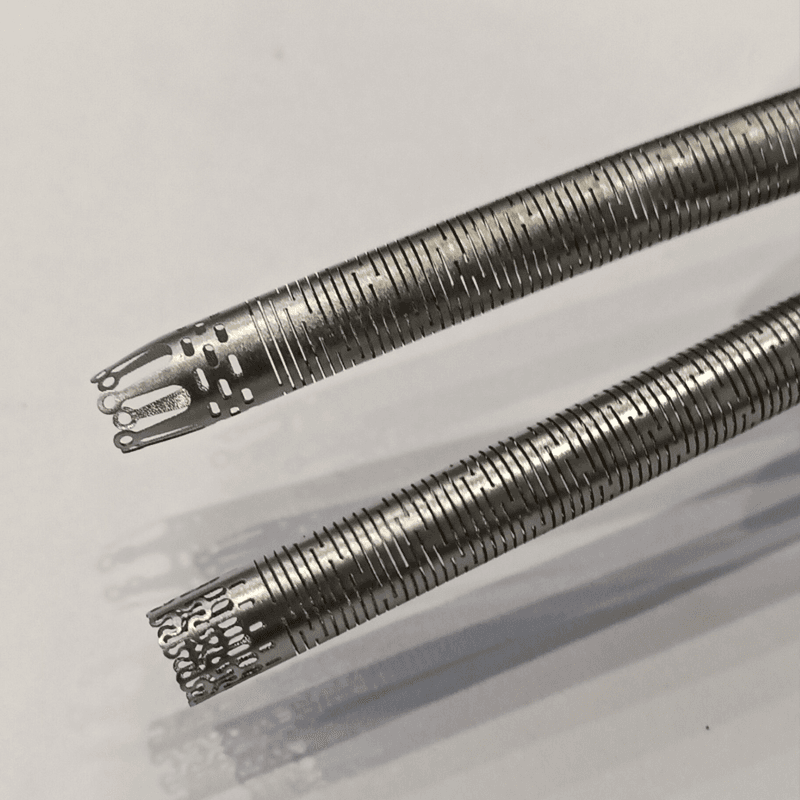

Medical: Stents, guidewires, and catheter systems

Aerospace: Actuators and vibration-resistant tubing

Industrial: Robotic systems and high-cycle sensors

Energy: Subsea and geothermal connectors under corrosive conditions

NITINOL TUBE EXPANSION BENEFITS

Our tubing delivers unmatched radial expansion and contraction cycles. The material recovers its original shape after 8% strain deformation, outperforming stainless steel or polymer alternatives. This makes it critical for self-expanding implants, dynamic seals, or temperature-triggered actuators.

Why Choose Our Tubing for Nitinol Tube Expansion?

Our tubing is tested for fatigue, pressure, and corrosion resistance, and meets ASTM F2063 standards. We offer fast shipping, engineering support, and full customization in diameter, temper, and coil form.

Get ahead with nitinol tube expansion that outperforms conventional materials. Contact us for free samples or to discuss your unique application.

Reviews

There are no reviews yet.