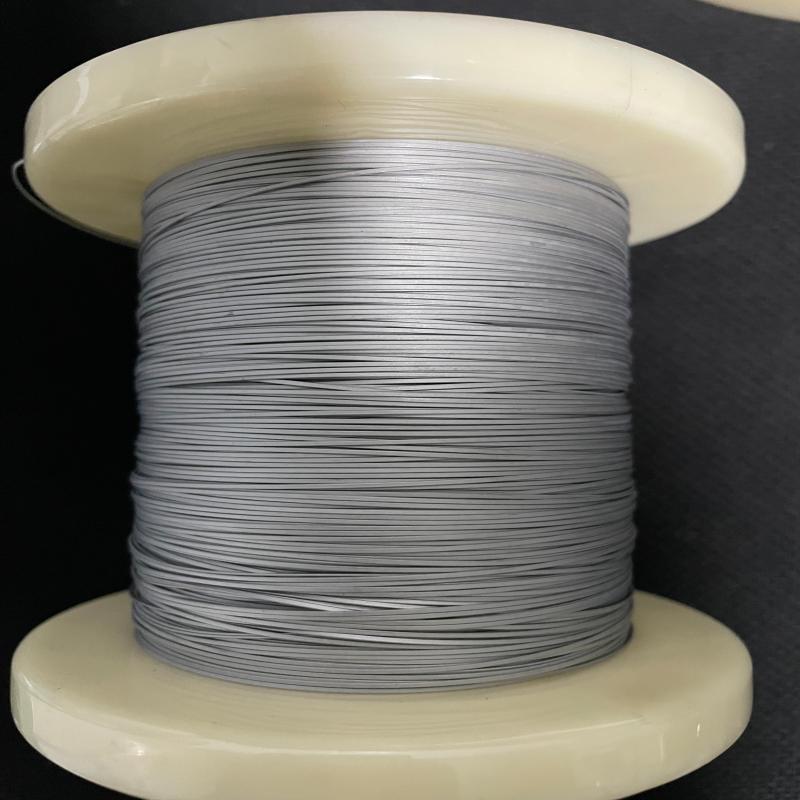

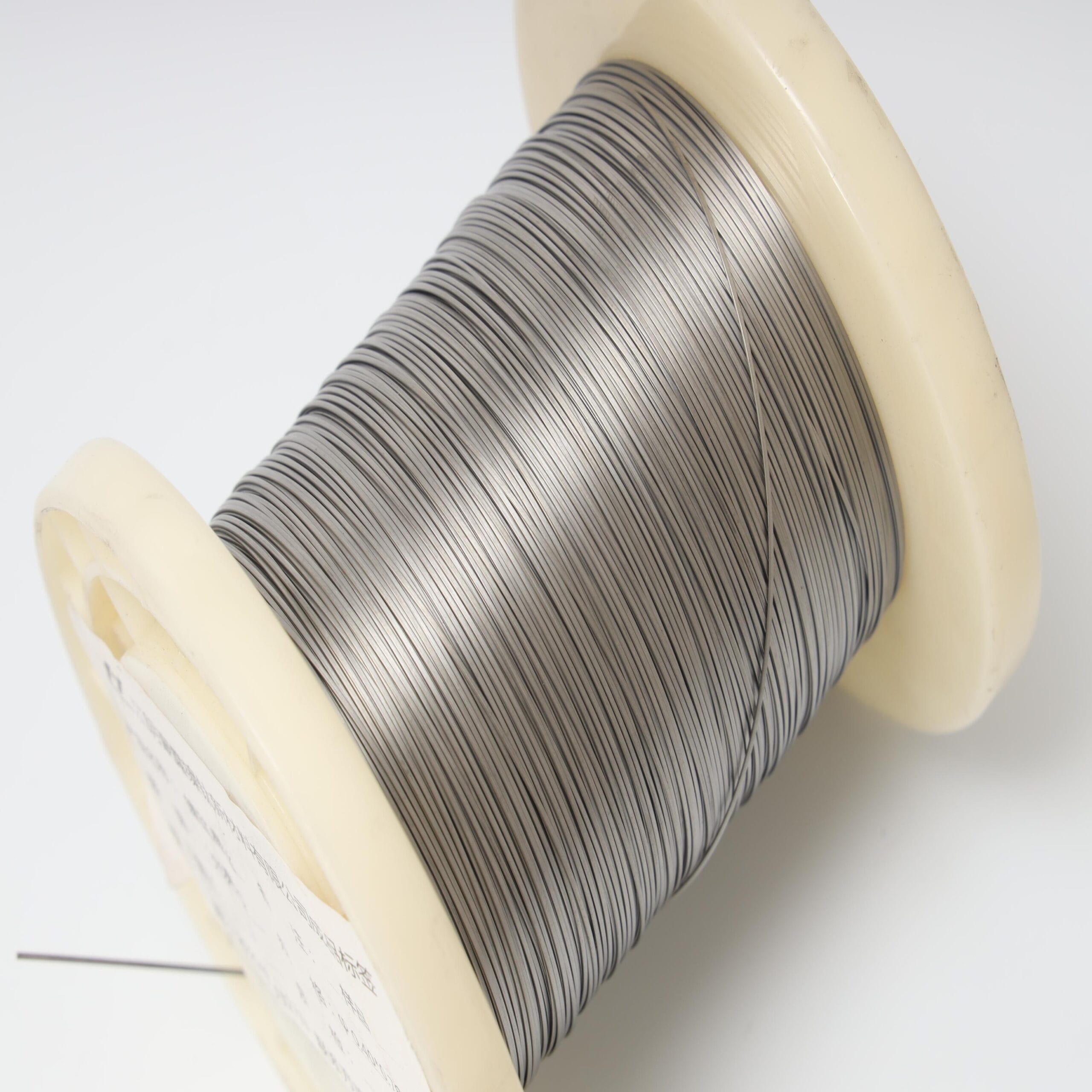

Nitinol Suppliers Strip – High Precision 0.05mm Alloy for Critical Applications

Introduction

As leading nitinol suppliers, we provide high-quality nitinol strip solutions designed for precision-critical industries. This ultra-thin 0.05mm nitinol suppliers strip is engineered with a balance of flexibility, durability, and superelastic performance—ideal for medical, aerospace, and electronics applications.

Material Composition of Our Nitinol Strip

We use premium-grade Nickel-Titanium Alloy to deliver a nitinol strip with outstanding shape memory and corrosion resistance. Strict quality checks maintain stable phase transitions and uniform mechanical properties in the alloy. Our expertise as nitinol suppliers allows us to meet rigorous standards for performance and reliability.

Surface Finish Options

The surface of our nitinol suppliers strip is engineered for functional longevity and superior biocompatibility. Options include:

Electropolished for ultra-smooth, friction-reducing finishes

Mechanically polished for bright, reflective surfaces

Customized treatments like oxidation or etching

Each finish maintains Ra ≤ 0.1 μm, ideal for surgical-grade or high-tech use.

Ultra-Thin Thickness Range

Our nitinol strip standard thickness is 0.05mm, with customizable options from 0.03mm to 0.5mm. We maintain a flatness tolerance of ±0.005mm to support advanced micro-engineering and miniaturized component designs.

Applications of Nitinol Suppliers Strip

Medical Devices

Catheters

Stents

Orthodontic wires

Surgical instruments

The material’s ability to ‘remember’ shapes and integrate safely with biological systems drives its use in medical applications.

Aerospace Components

Satellite deployable structures

Actuators

Vibration isolators

Fatigue resistance and low weight make the strip ideal for mission-critical environments.

Electronics & Sensors

Precision connectors

Temperature-responsive micro-springs

Compact sensors

Nitinol’s electrical and mechanical properties enhance miniaturization.

Automotive Innovation

Fuel delivery systems

Adaptive safety components

Micro-actuated valves

Withstands extreme temperatures and mechanical stress.

Why Engineers Choose Our Nitinol Strip

1. Certified Quality from Expert Nitinol Suppliers

Complies with ISO 13485, ASTM F2063, and medical-grade specifications. Each nitinol suppliers strip batch is tested for transformation temperature and alloy uniformity.

2. Tailored Strip Solutions

We provide customizable widths, finishes, and heat treatments. Prototyping and low-volume production are available to match your innovation timeline.

3. Global Logistics & On-Time Delivery

Our optimized supply chain ensures timely delivery worldwide. Even urgent or small-batch nitinol strip orders are fulfilled efficiently.

4. End-to-End Technical Support

From alloy selection to product development, our engineers collaborate with clients to enhance functionality and reduce cost.

5. Cost Efficiency Without Compromise

We combine high-volume procurement and lean manufacturing to offer premium-grade nitinol suppliers strip at competitive rates.

6. Environmentally Responsible

We recycle scrap materials and use energy-efficient manufacturing to reduce our carbon footprint.

Order Now

Choose Precision Nitinol Suppliers Strip 0.05mm—trusted by innovators across medical, aerospace, and tech sectors. Contact us for a fast quote, technical consultation, or free sample.

Reviews

There are no reviews yet.