Precision Nitinol Shape Components for High-Performance Applications

Premium Material: Nickel-Titanium Alloy with Superior Shape Memory

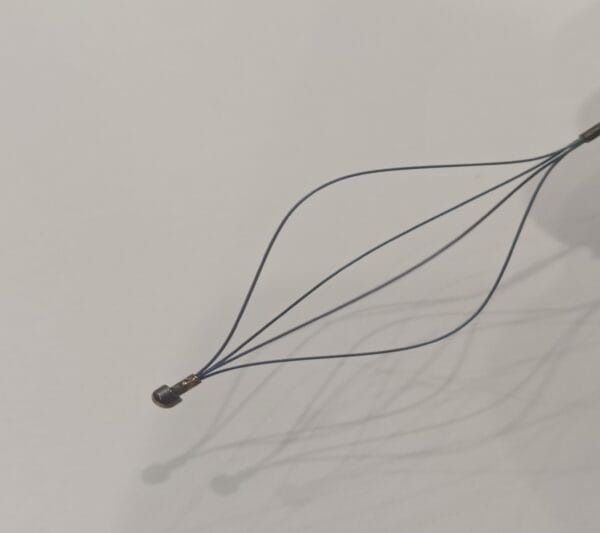

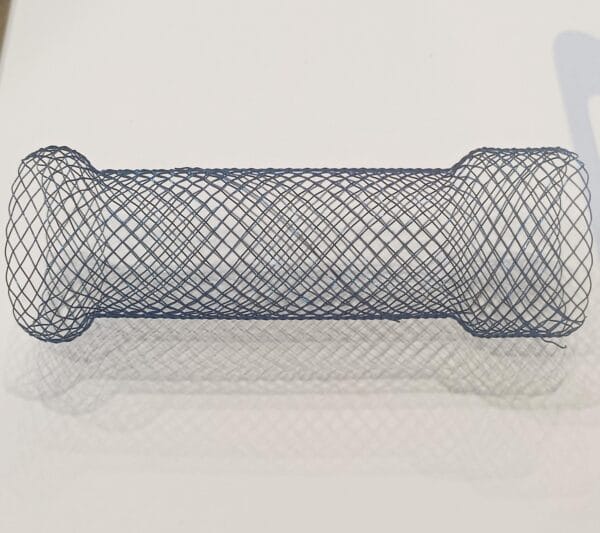

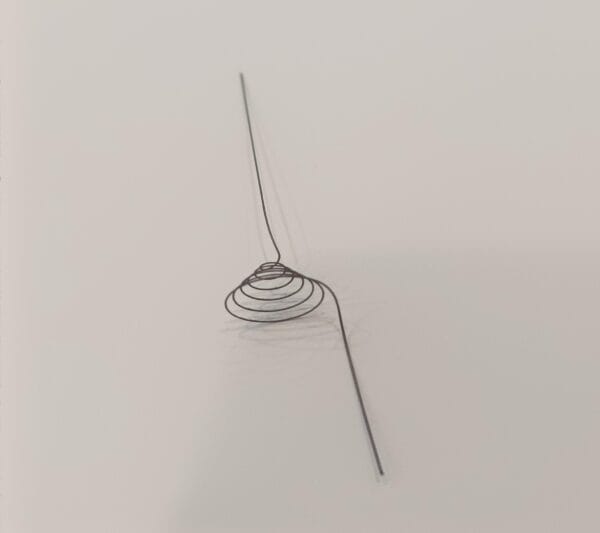

Our Nitinol shape components are manufactured using premium Nickel-Titanium (NiTi) alloy, well-known for its outstanding shape memory effect and superelastic properties. Composed of nearly equal parts nickel and titanium, this smart material offers outstanding biocompatibility, corrosion resistance, and mechanical durability. It performs reliably under extreme temperatures, repetitive stresses, and cyclic motion without deformation or loss of functionality.

Customizable Surface Finishes to Meet Application Needs

We supply various surface finishing choices designed to suit different application needs.Electropolishing delivers ultra-smooth surfaces that resist corrosion and minimize friction, ideal for precision medical devices. Mechanical polishing ensures bright, clean appearances for visible components. For implantable or biomedical applications, our advanced passivation treatments enhance biocompatibility by removing surface impurities. Custom surface roughness and aesthetics are also available upon request.

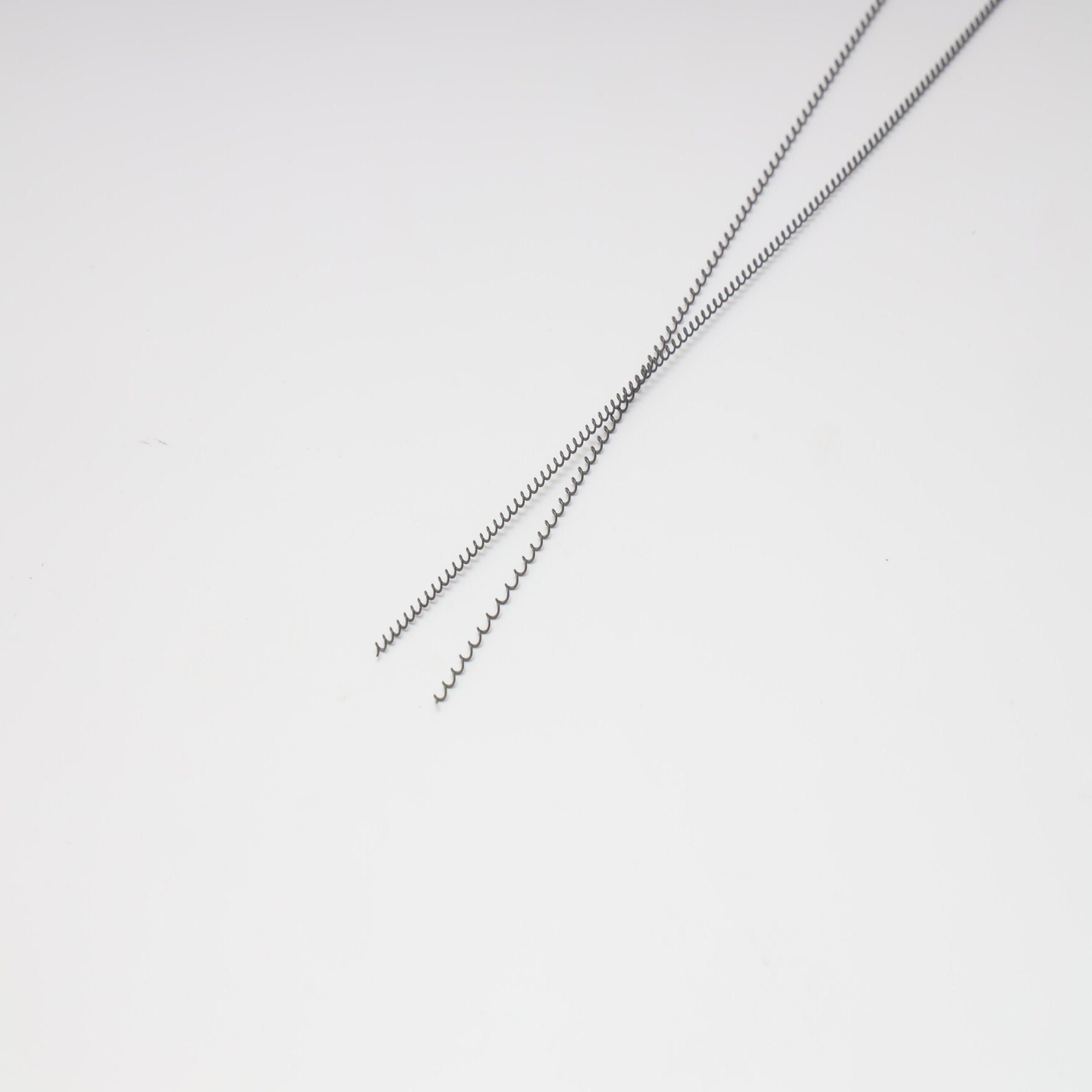

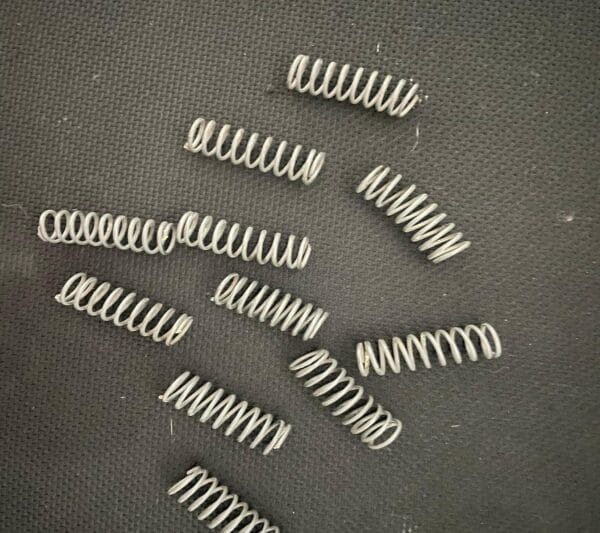

Versatile Diameter Range from Micro to Industrial Scale

Our nitinol shape components are available in diameters from 0.1 mm to 5.0 mm, covering micro-scale medical devices to robust industrial parts. Fine wires (0.1–1.0 mm) are perfect for guidewires, stents, and sensors. Mid-range sizes (1.0–3.0 mm) fit actuators, orthodontic wires, and robotic mechanisms. Larger diameters (2.5–6.0 mm) support aerospace fittings and energy sector equipment.

Diverse Applications Across Multiple Industries

Medical Devices: Reliable shape memory ensures precise deployment in minimally invasive surgery, vascular stents, and orthodontics.

Industrial Systems: Actuators, couplings, and safety valves benefit from temperature-responsive motion control.

Consumer Electronics: Durable hinges and compact mechanisms in smartphones and wearables leverage nitinol shape properties.

Aerospace: Components endure harsh conditions in satellites and vibration dampers.

Energy: Solar trackers and oil/gas valves use corrosion-resistant, self-adjusting solutions.

Why Choose Our Nitinol Shape Components?

Precision Shape-Setting: Utilizing advanced heat treatment techniques, we program exact shapes that consistently recover after thousands of cycles.

Strict Quality Assurance: We conduct comprehensive testing in accordance with ASTM F2063 and ISO 13485 standards to guarantee consistent material properties, precise transformation temperatures, and excellent resistance to fatigue.

Tailored Customization: Specify dimensions, transition temperatures (Af: -20°C to 120°C), and force outputs to optimize performance.

Fast Delivery: Prototypes ready within 10 days; full production orders in 4–6 weeks.

Competitive Pricing: Lean manufacturing and bulk sourcing lower costs without sacrificing quality.

Technical Support: Experienced engineers provide design advice, material selection help, and troubleshooting expertise.

▸ Expert Guidance: 24/7 support via nitinolalloy.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.