Nitinol Rope 1×7 – Super-Elastic Alloy Cable for High-Precision Applications

Introduction

Nitinol rope stands out as a next-generation material that offers a rare blend of flexibility, shape memory, and mechanical strength. Engineered from premium nickel-titanium alloy, this innovative rope adapts to variable loads while maintaining performance reliability. Its unique properties make it highly suitable for advanced sectors like aerospace, medical technology, robotics, and precision electronics.

Engineered Structure for Reliable Performance

Our 1×7 nitinol rope features seven ultra-fine alloy filaments helically wound into a compact, high-strength strand. This configuration optimizes load-sharing capacity, enhances fatigue life, and supports phase transition behavior—allowing the rope to recover its original form after deformation or thermal cycling.

Available Surface Finishes

To support various environments and assembly requirements, our nitinol ropes are available in two protective finishes:

Black Oxide – Offers a matte, corrosion-resistant surface ideal for sterile or non-reflective conditions.

Light Oxide – A natural finish ranging from gold to brown that enhances part visibility and aesthetic integration.

Wide Diameter Range for Versatile Use

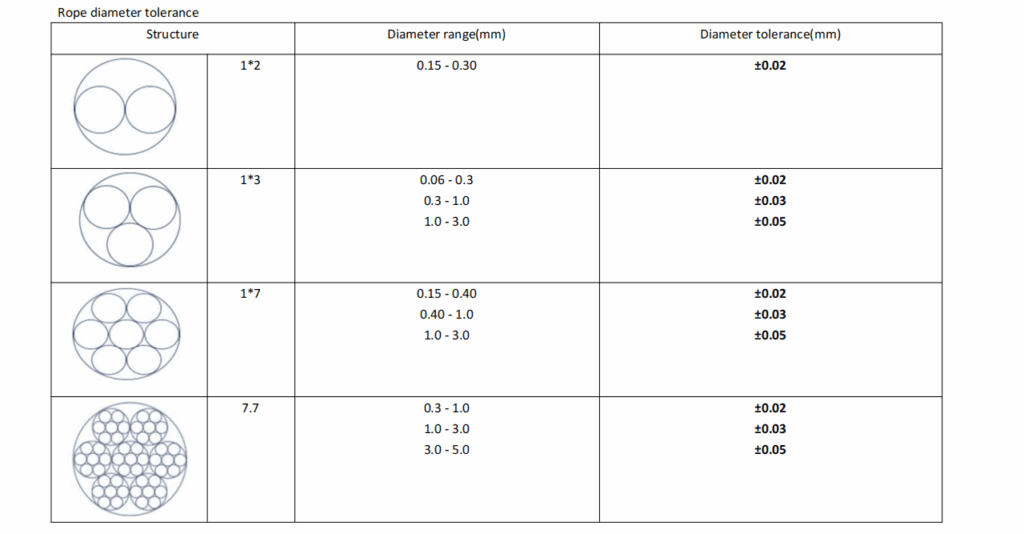

We provide diameter options from 0.1 mm to 5.0 mm, ensuring compatibility with applications from microsurgery instruments to aerospace cable systems. Whether precision or strength is your top priority, our dimensional flexibility supports both.

Key Benefits of 1×7 Nitinol Rope

Super-Elastic Properties – Bends easily without permanent set, ideal for compact or moving assemblies.

Shape Memory Effect – Returns to a predefined shape upon heating or unloading.

Extended Fatigue Life – Resists failure across millions of load cycles.

Biocompatibility – Suitable for contact with skin and internal human tissue.

Ease of Installation – Handles similarly to stainless steel cables, simplifying process integration.

Industry Applications

Our nitinol ropes have proven performance in demanding fields:

Medical Devices – Ideal for guidewires, orthodontics, catheters, and endoscopic tools.

Aerospace Systems – Deployed in actuators, damping systems, and space-saving structural elements.

Robotics – Enables joint motion, flexible feedback cables, and reconfigurable systems.

Consumer Electronics – Used in folding mechanisms, spring structures, and mini connectors.

Energy & Infrastructure – Supports high-temperature cable runs and deployable solar arrays.

Performance vs. Conventional Materials

Compared to traditional steel or polymer cables, nitinol ropes offer:

Reliable function in extreme environments (–50°C to +150°C)

Minimal wear during repeated deformation

Superior energy return and memory-based motion control

Direct compatibility with conventional cable fixtures and tools

Packaging and Custom Lengths

We offer standard spools, EDM-cut lengths, shear-cut segments, or application-specific packaging. Whether you’re in early-stage development or mass production, our flexible supply formats reduce waste and save assembly time.

🔗 Internal Links to Add

▸ Expert Guidance: 24/7 support via nitinolwire.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.