Nitinol (Ni-Ti) Spring – Advanced Shape Memory Alloy Solution

What Is a Nitinol (Ni-Ti) Spring?

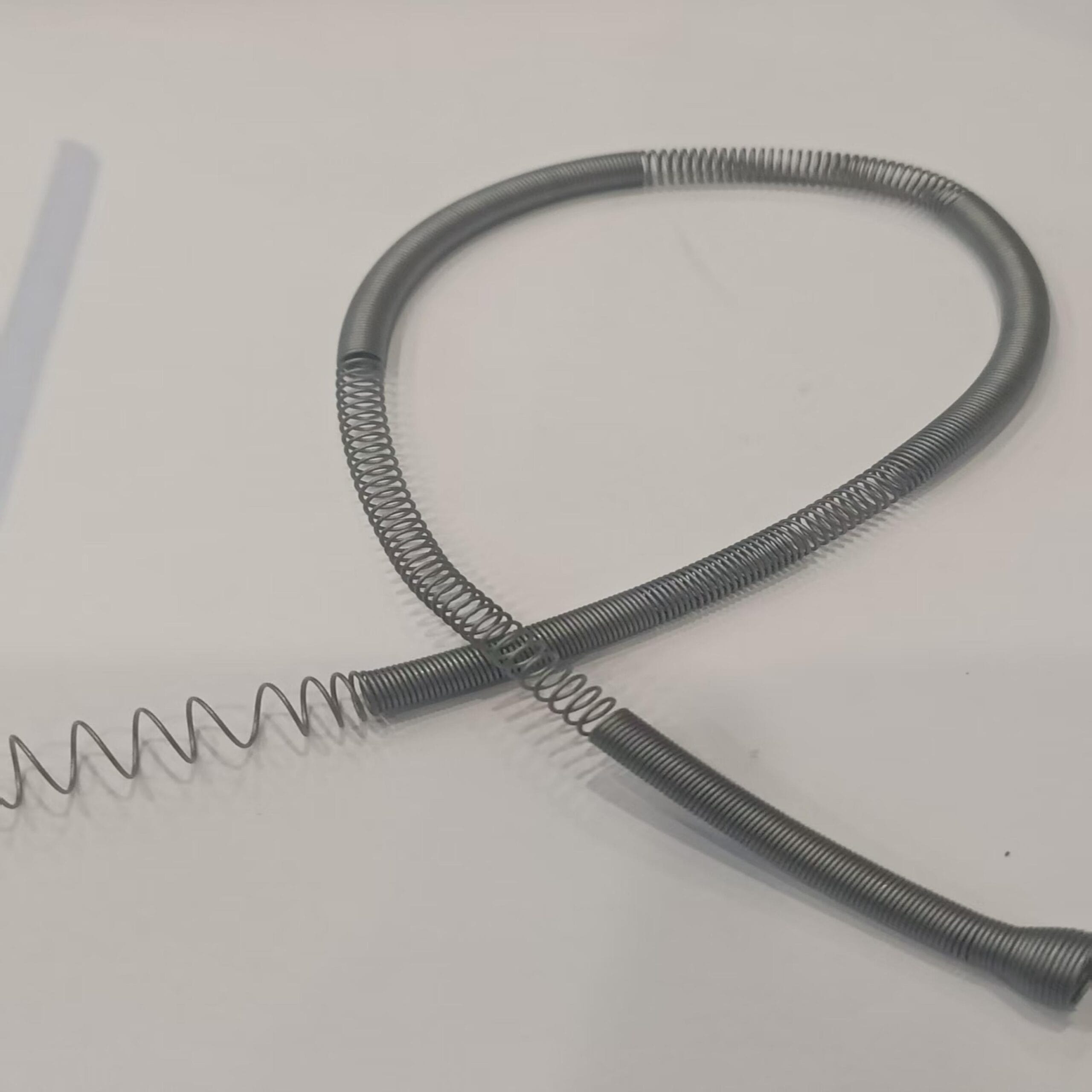

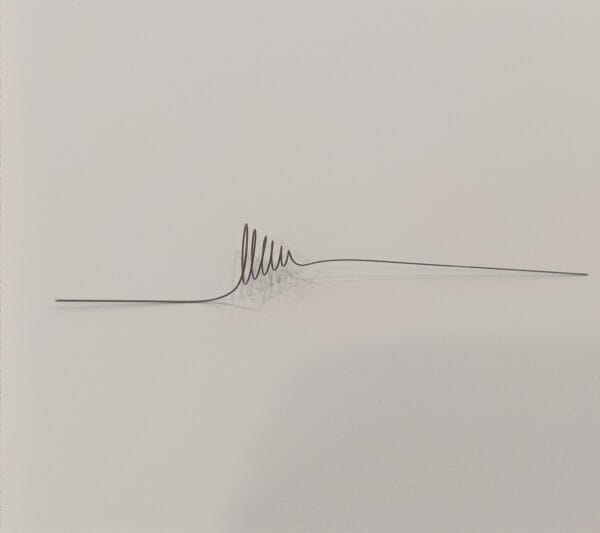

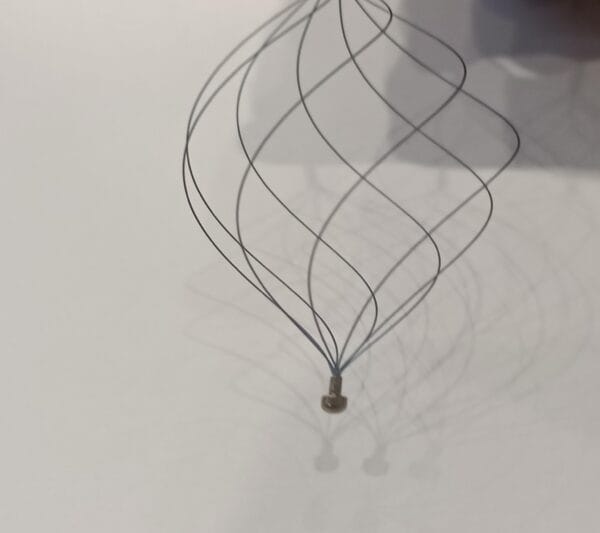

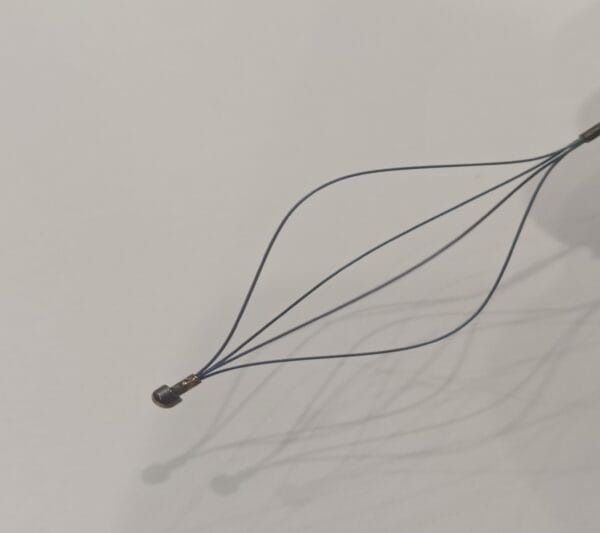

Our factory manufactures high-quality nitinol (Ni-Ti) springs, engineered from a unique nickel-titanium alloy known for its exceptional functional properties. Nitinol exhibits superelasticity and the shape memory effect, allowing the spring to undergo extreme bending, compression, or extension and then fully return to its original form with consistent force.

Unlike conventional metal springs, a nitinol spring delivers reliable motion even under repeated stress. This capability makes it an ideal solution for applications that demand precision, durability, and intelligent mechanical response.

Material Composition – Medical-Grade Nickel Titanium Alloy

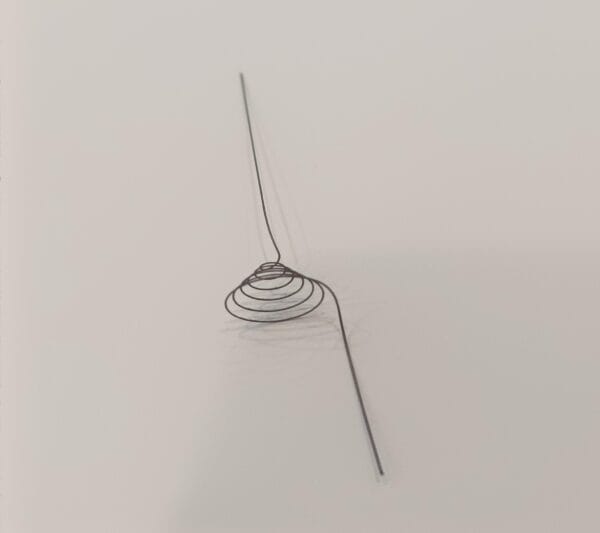

Each nitinol (Ni-Ti) spring is produced using premium nitinol wire composed of nearly equal parts nickel and titanium. Precise alloy composition is critical, as it directly determines transformation temperatures, spring force, and fatigue life.

Our materials meet strict industrial and medical standards. The alloy offers excellent mechanical strength, superior wear resistance, and outstanding corrosion resistance. It performs reliably in saltwater, humid environments, and bodily fluids, making it especially suitable for medical and dental applications.

How a Nitinol Spring Works

A nitinol spring functions based on temperature-dependent phase transformation. At higher temperatures, the alloy enters the austenite phase, where it becomes strong and rigid. At lower temperatures, it transitions to the martensite phase, which is softer and more flexible.

By controlling alloy chemistry and heat treatment, we can precisely adjust the transformation temperature range. As a result, the nitinol (Ni-Ti) spring delivers a remarkably constant force over a long stroke, outperforming traditional steel springs in both stability and repeatability.

Product Description & Customization Options

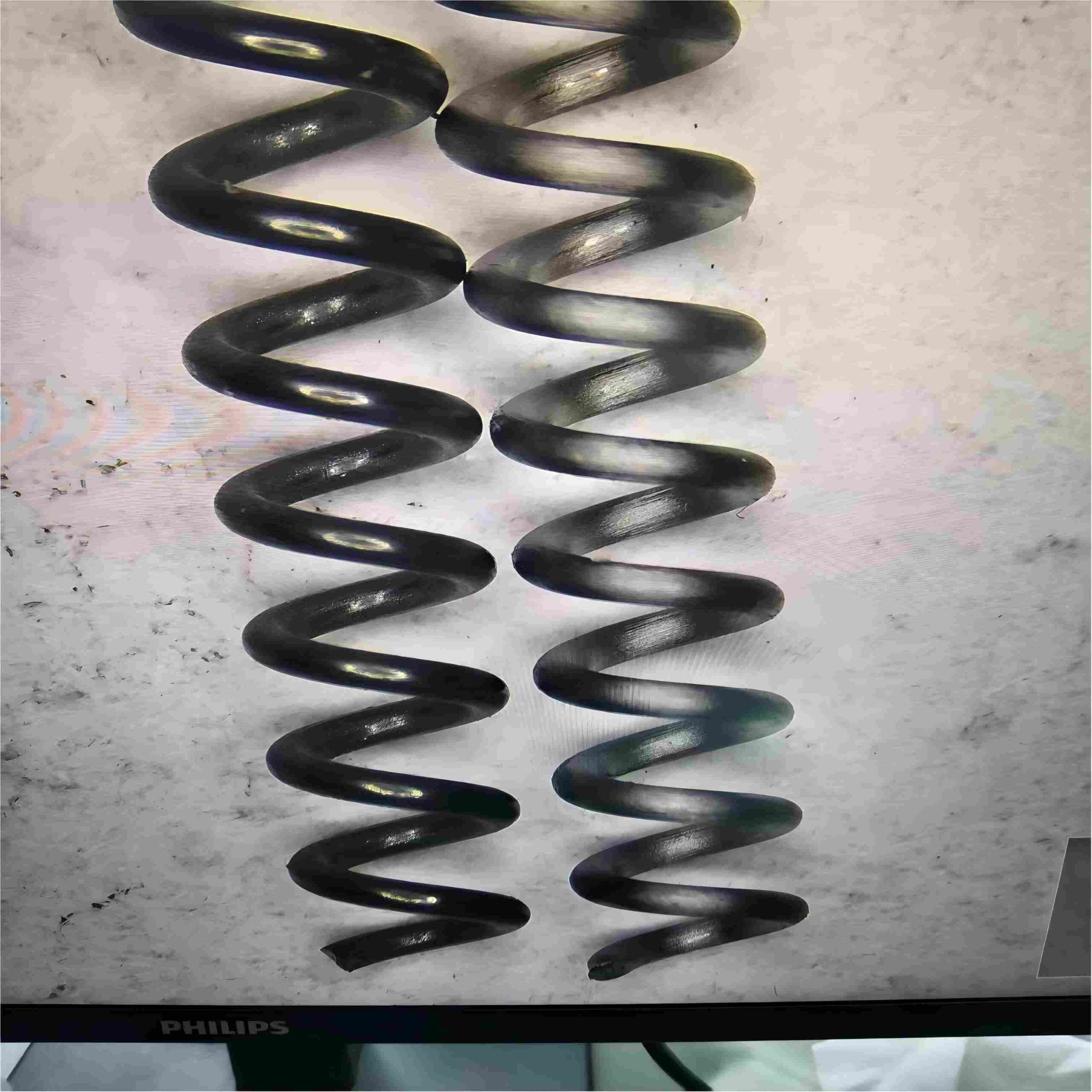

Our nitinol springs are precision-formed coil springs designed to fully utilize the alloy’s superelastic and shape memory characteristics. When deformed, the spring recovers completely without permanent damage. When heated, it powerfully returns to its memorized shape.

We offer extensive customization, including:

Wire diameter and coil diameter

Spring length and pitch

Load force and activation temperature

Compression, extension, or torsion spring designs

Each spring is engineered for consistent performance across millions of cycles.

Manufacturing Capabilities & Quality Control

As a specialized nitinol manufacturer, we control every step of production. From precision wire drawing and spring forming to advanced heat treatment, each process is tightly monitored. Heat treatment defines the spring’s memory behavior and transformation temperatures.

We conduct rigorous testing for force output, fatigue life, dimensional accuracy, and thermal response. Whether you need prototypes or mass production, we provide reliable solutions tailored to your application.

Key Advantages of Nitinol (Ni-Ti) Springs

Extremely constant force over long travel distances

Exceptional fatigue resistance with millions of cycles

Biocompatible and safe for medical implantation

Excellent corrosion resistance in harsh environments

Lightweight yet high mechanical strength

Enables compact, intelligent, and adaptive designs

Typical Applications of Nitinol Springs

Nitinol springs are widely used across multiple industries:

Dentistry: Orthodontic systems that apply gentle, continuous force for efficient tooth movement

Medical Devices: Stents, surgical tools, and minimally invasive instruments

Optics: Flexible eyewear frames with high durability

Thermal Control: Heat-activated switches and valves

Fire Safety: Automatic sprinkler and ventilation activation systems

Conclusion

Our nitinol (Ni-Ti) spring is a smart, high-performance component designed for demanding environments. Combining shape memory, superelasticity, long service life, and reliable force output, it delivers unmatched performance compared to conventional springs.

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

Reviews

There are no reviews yet.