Advanced Metal Sheet Solutions with Shape Memory Performance

The nitinol metal sheet combines strength, flexibility, and thermal response. Made from a nickel-titanium alloy, this smart material supports innovation across medical, aerospace, and industrial sectors. It’s valued for both shape memory behavior and high fatigue resistance.

Precision Alloy Engineering

Engineered with a 55.8% Nickel and 44.2% Titanium composition (±0.15%), the sheet offers exceptional consistency. Purity reaches 99.995%, minimizing intermetallic formation. Additionally, each batch comes with traceable certification, including ISO 13485 and AS9100. Austenite finish temperatures are fully customizable from –20°C to +110°C.

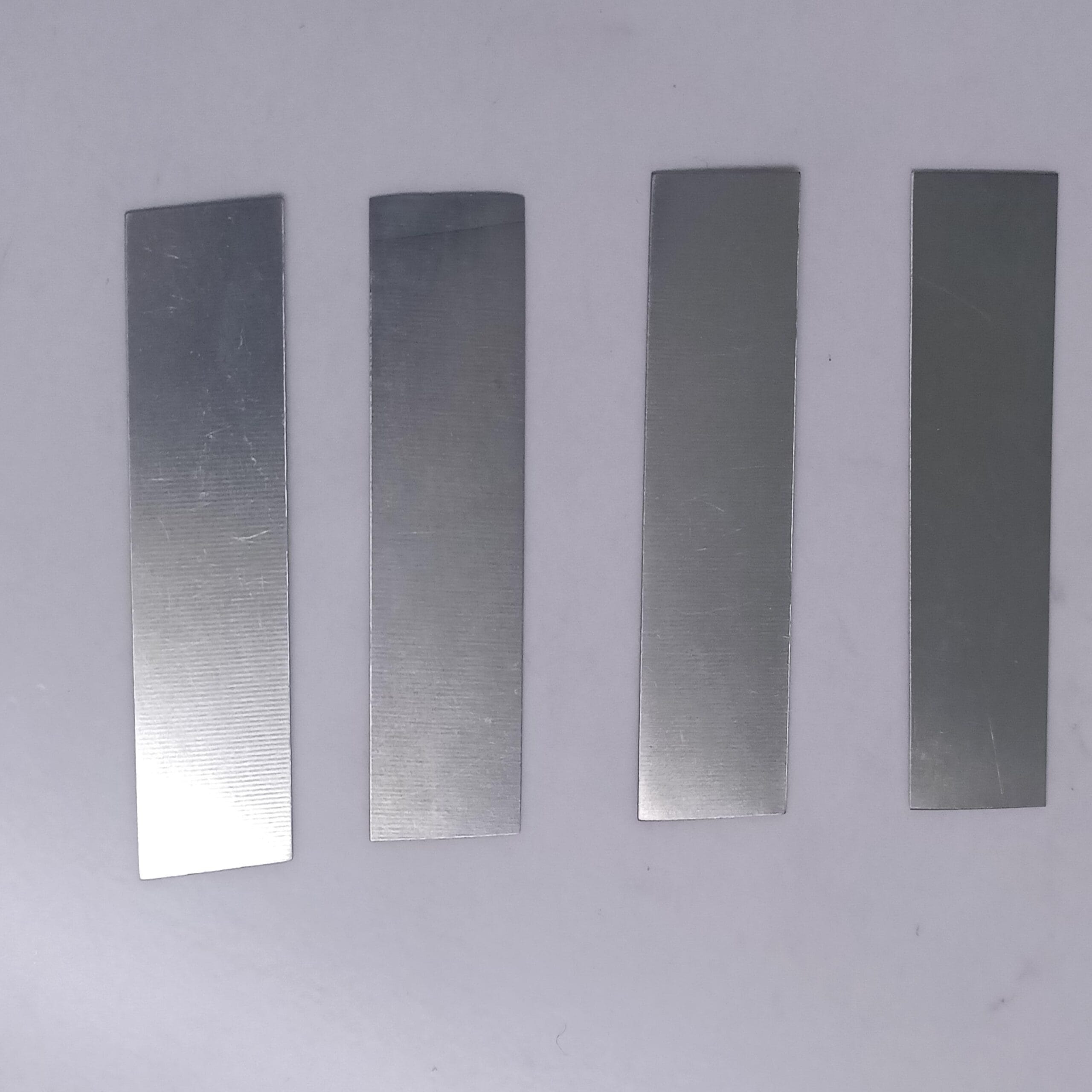

Custom Surface Finishes

To suit different industry needs, we offer four types of surface finishes:

| Finish Type | Ra (μm) | Highlights | Used For |

|---|---|---|---|

| Mirror Electropolish | ≤ 0.05 | Particle-free, ultra-smooth | Implants, microscopy parts |

| Micro-blasted Matte | 0.8–1.2 | Enhances coating adhesion | Aerospace hardware |

| Thermal Oxide | 1.5–2.0 | Adds wear resistance (HV 650+) | Industrial forming dies |

| Passivated | 0.3–0.5 | Bioprocess-ready, ASTM F86-compliant | Surgical and lab instruments |

These finish options help boost the sheet’s performance in real-world conditions.

Versatile Dimensions and Tight Tolerances

Available in thicknesses ranging from 0.05 mm to 15 mm, the sheets serve both lightweight and structural needs. Tolerances remain tight—within ±0.5% for thin formats and ±1% for thicker ones. For complex designs, we support photochemical etching, micro-perforation, and laser cutting with 50 μm kerf width.

Reliable Testing and Fatigue Resistance

Each sheet undergoes detailed performance testing, including:

Recoverable strain up to 300% (ASTM F2516)

10⁷-cycle fatigue life at 3% strain

Consistent transformation temperature (±1.5°C)

These tests ensure that the product performs under pressure and across thermal cycles.

Medical and Aerospace Application Versatility

In the medical field, nitinol supports advanced functionality. Examples include:

MRI-compatible stents

Orthodontic components delivering precise force

Flexible surgical instruments lasting through high cycle loads

For aerospace engineers, the material aids in:

Cryogenic actuators working at –196°C

Vibration mounts absorbing up to 90% energy

Thermal-coupled assemblies in fuel systems

Production Quality and Technical Support

We use a VIM/VAR triple-melt process that limits inclusions to less than 10 ppm. Each batch is:

Verified by EDX analysis

Scanned for 3D surface mapping

Examined for transformation hysteresis

Subjected to strain-based fatigue validation

Compliance includes RoHS, REACH, and FDA 510(k) standards. Cleanroom handling ensures product integrity during packing and delivery.

Fast Turnaround and Support Services

Time-sensitive projects benefit from:

48-hour prototyping for samples under 500g

98% same-day shipping for stocked items

Metallurgist support with average response time under 2 hours

These services help teams stay ahead on development timelines.

Reviews

There are no reviews yet.