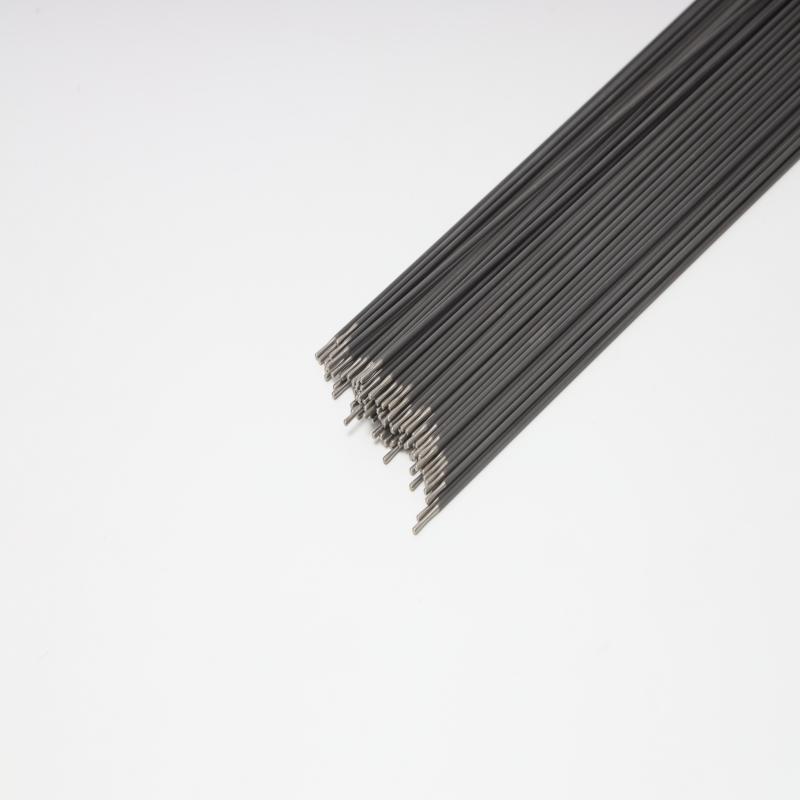

Nitinol Metal Rod for High-Performance Applications

Premium NiTi Alloy with Superior Functional Properties

We manufacture our nitinol metal rod using high-grade nickel-titanium (NiTi) alloy, precisely balanced in nearly equal proportions.Because of this unique composition, the rod demonstrates both shape memory and superelasticity. For example, it returns to its original shape when heated and bends extensively without permanent deformation. These characteristics make it highly suitable for demanding applications where durability, flexibility, and temperature resilience are essential.

Tailored Surface Finishes for Specific Uses

To meet various industrial and medical requirements, we offer several finish options:

Polished surfaces minimize friction and improve biocompatibility, especially for surgical tools.

These non-reflective finishes are ideal for applications in robotics and heavy industry where glare must be minimized.

Etched surfaces increase adhesion strength, which supports coatings or bonding processes.

Additionally, every finish goes through strict inspections to ensure consistency and long-term durability.

Wide Diameter Range with Tight Tolerances

Our nitinol rods are available in diameters from 0.5 mm to 20 mm, covering both micro-scale and heavy-duty applications.

Thin rods (0.5–2 mm) are often used in medical devices, electronics, and precision mechanisms.

Thicker rods (5–20 mm) serve well in automotive, aerospace, and industrial engineering.

Importantly, we maintain tight tolerances of ±0.05 mm, allowing for exact integration into advanced systems.

Diverse Applications Across Industries

Thanks to its adaptability, the nitinol metal rod supports a broad spectrum of applications:

In healthcare, it is used for stents, orthodontic wires, guidewires, and surgical instruments.

In aerospace, nitinol rods enhance actuators, damping systems, and satellite deployment arms.

Automotive engineers use them for fuel injection systems and temperature-sensitive actuators.

In robotics and industrial control systems, the rods contribute to precise movement and fail-safe designs.

In the electronics industry, thin rods function in microactuators and sensor linkages.

Moreover, in renewable energy, they assist in developing smart solar tracking mechanisms.

Why Our Nitinol Metal Rod Stands Out

We directly control production using advanced melting, machining, and finishing technologies. We test each batch thoroughly—for phase transformation, composition, and mechanical integrity—before delivery. All orders include certified material documentation.

Welding-Formed Nitinol Rod Assemblies

To expand versatility, we provide welding-formed parts. Our skilled technicians weld nitinol rods to plates, tubes, or complex geometries. By applying controlled post-weld heat treatments, we maintain alloy performance and restore the surface for long-term reliability.

Reliable Customization and Support

We understand that each project has unique demands. That’s why we offer:

Rapid turnaround for urgent orders

Customization in rod size, finish, and welded form

Free samples for evaluation

Ongoing technical support to help with specification selection and design challenges

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolalloy.com

Mid East Region:getnitinol.com

Reviews

There are no reviews yet.