Nitinol Memory Wire Engineering Selection Framework

Precision Actuation Solutions for Medical & Industrial Systems

As the premier shape-memory actuator material, Nitinol memory wire enables transformative performance in advanced engineering applications. This technical framework outlines critical selection criteria based on ASTM F2063 and ISO 5832-11 standards, ensuring optimal implementation across thermal-mechanical systems.

Core Performance Optimization

1. Phase Transition Dynamics

Nitinol memory wire exhibits temperature-dependent actuation efficiency, demonstrated through several key factors:

Austenite Finish (A<sub>f</sub>) Control: The 40°C grade achieves a rapid 0.9-second response time compared to the 80°C grade’s 2.3 seconds in aqueous activation.

Hysteresis Management: Thermal windows between 28-35°C enable precise cyclic behavior.

Strain Recovery: At 500MPa stress, the wire offers 6-8% fully recoverable deformation.

2. Thermal-Mechanical Coupling

Performance parameters vary by grade:

| Parameter | 15°C Grade | 40°C Grade | 80°C Grade |

|---|---|---|---|

| Activation Speed | 1.2s | 0.9s | 2.3s |

| Cycle Frequency | 0.8Hz | 1.5Hz | 0.6Hz |

| Max Load Capacity | 45N | 60N | 85N |

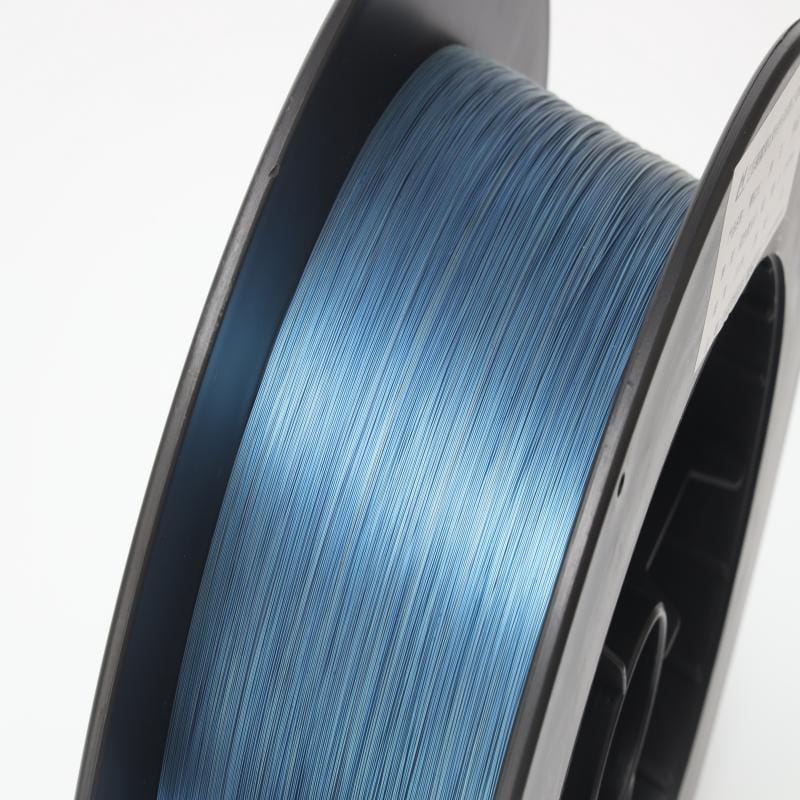

3. Diameter Optimization Strategy

Different diameter ranges suit varied applications:

0.1–0.5mm supports high-speed microactuation with response times under 0.5 seconds.

0.5–1.0mm balances force and speed for mid-range performance.

1.0–2.0mm handles high-force macro-scale applications.

Advanced Material Specifications

Structural Architecture: The surface comprises a TiO<sub>2</sub> oxide layer with Ra values between 0.2–0.4μm and hardness of HV 320–380.

Crystalline Structure: Features a B2-phase matrix with less than 2% R-phase content.

Self-Healing Capability: Demonstrates 85% dislocation recovery at 0.2% tensile strain.

Operational Limits

Electrical: Maximum current density limited to 45 mA/mm².

Thermal: Automatic cutoff occurs at A<sub>f</sub> + 20°C to protect material integrity.

Mechanical: The wire sustains up to 10⁷ cycles durability at 3% strain.

Implementation Protocols

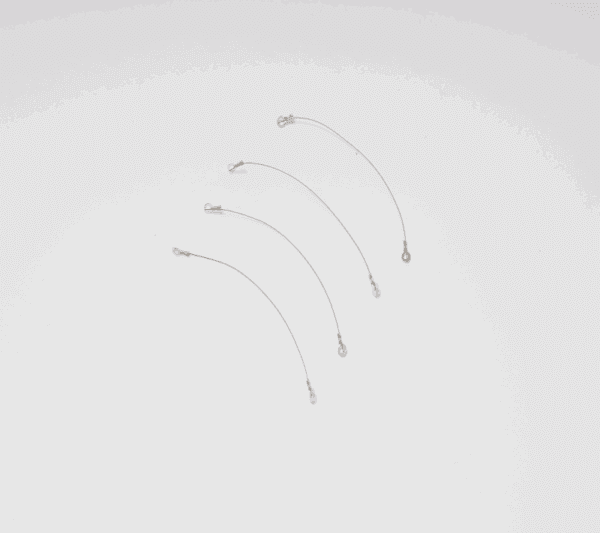

Medical Device Integration

Various medical uses leverage specific wire grades:

Vascular implants commonly use 0.15mm 40°C wires for precise stent deployment.

Orthopedic tools incorporate 1.0mm 80°C variants for bone anchoring.

Surgical robotics benefit from 0.3mm 15°C wires designed for micro-actuation.

Industrial Automation

In industry, wire specifications include:

0.5mm 40°C wire for valve control cycling at 1.2Hz.

1.2mm 60°C wire operating HVAC dampers across -20°C to 80°C.

2.0mm 80°C wire applied in heavy-duty actuators bearing continuous 85N load.

Technical Support Ecosystem

Trial kits include a 10-size assortment from 0.1 to 1.0mm.

Complimentary DSC testing provides material analysis support.

Additionally, 24/7 technical assistance is available through our official support portal.

Expert Guidance: 24/7 support

Facebook account:Facebook

Back to the products

Reviews

There are no reviews yet.