Advanced Nitinol tube development processing Innovation

Our company excels in producing precision Nitinol laser-cut hypotubes. We support every stage of medical device development with expert material processing and cutting-edge manufacturing techniques. Our hypotubes enable the next generation of minimally invasive surgical tools, offering superior performance and reliability.

Superior Material: Nitinol Alloy

As a functional shape-memory alloy, Nitinol’s superelasticity and thermal memory enable revolutionary medical devices.It offers exceptional superelasticity and shape memory capabilities, making it a top choice for demanding medical applications. This biocompatible material combines high strength with outstanding flexibility, allowing medical devices to navigate complex anatomy safely.

Unmatched Strength and Flexibility

Nitinol is among the strongest and most flexible metals available for medical use. It exhibits pseudoelasticity, allowing it to withstand substantial strain and fully recover its initial configuration. This superelastic property ensures medical devices can bend and twist through delicate pathways while maintaining structural integrity.

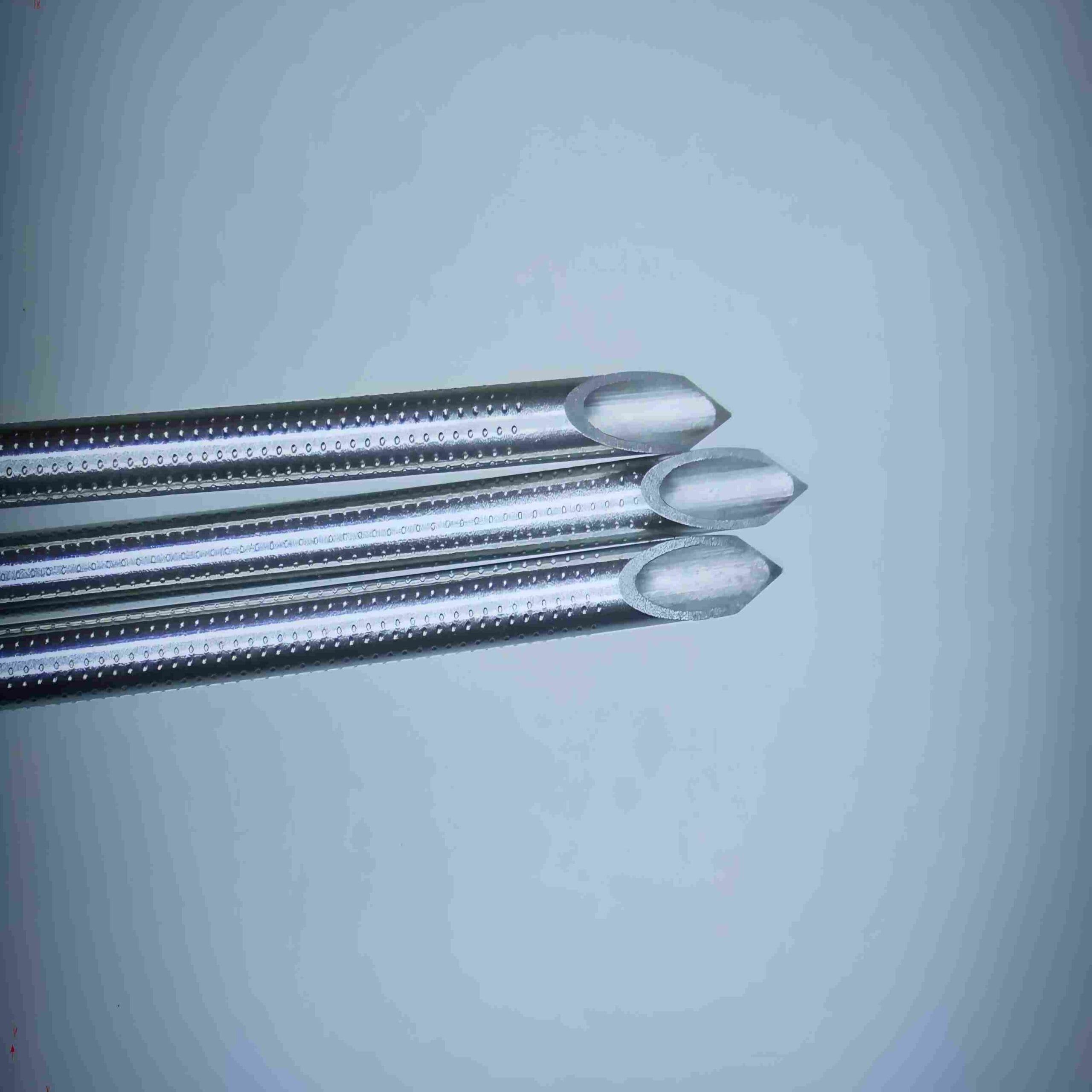

Precision Laser Cutting Technology

We employ state-of-the-art laser technology to fabricate complex micro-precision geometries on Nitinol tube development processing. Our process ensures clean, precise cuts without compromising material properties. This allows for customized designs that meet specific device requirements, from cardiovascular catheters to neurological guidewires.

Why Nitinol Commands Premium Value

The high cost reflects expensive raw materials, complex manufacturing, and stringent quality control. Medical-grade processing requires specialized equipment and expert handling throughout melting, forming, and finishing stages. Every step ensures superior biocompatibility and performance.

Custom Sizing Capabilities

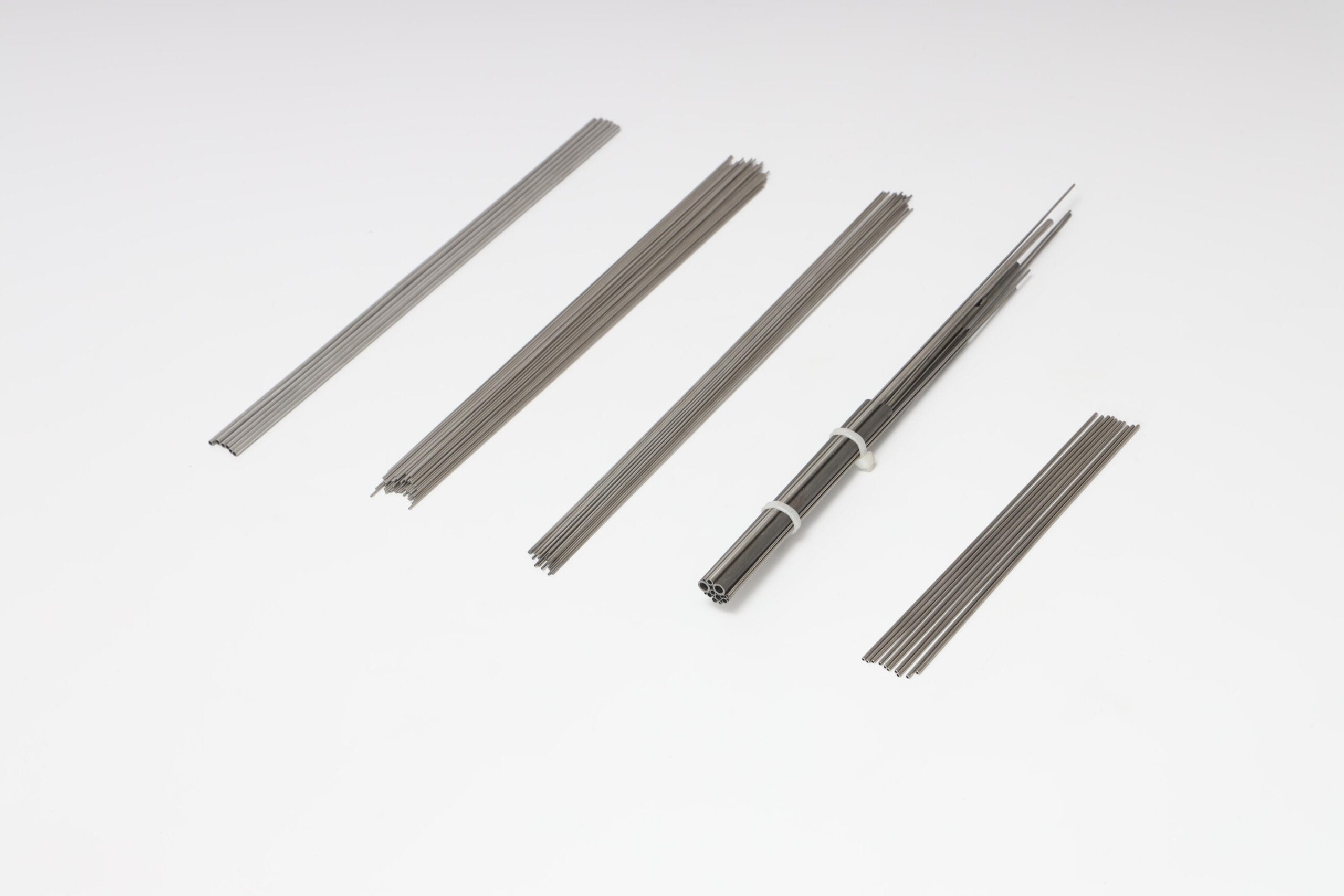

We offer hypotubes in an extensive range of diameters and wall thicknesses:

Outer Diameter: 0.5mm to 5.0mm

Wall Thickness: 0.05mm to 0.3mm

Custom configurations are available for specialized applications.

Mechanical properties

| Af temp | The finial temperature of factual action recovery can be tested using bending recovery method specified in ASTM F2082/F2082M-16 |

| Surface | Outer surface:oxidized state,round state Inner surface:clean state |

| Pipe Length | The length can be divided into precise or arbitrary lengths |

| Straightness | The requirement for straightness is negotiable |

| Surface defects | The requirements for surface defects can be negotiated |

| Applications | Medical:wave tube,camera tube,bracket,net basket,catheter |

Your Development Partner

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

Reviews

There are no reviews yet.