Ultra-Thin Nitinol Hypotube for Advanced Medical Devices

Engineered Precision for Minimally Invasive Breakthroughs

Discover Our Premium Nitinol Hypotube

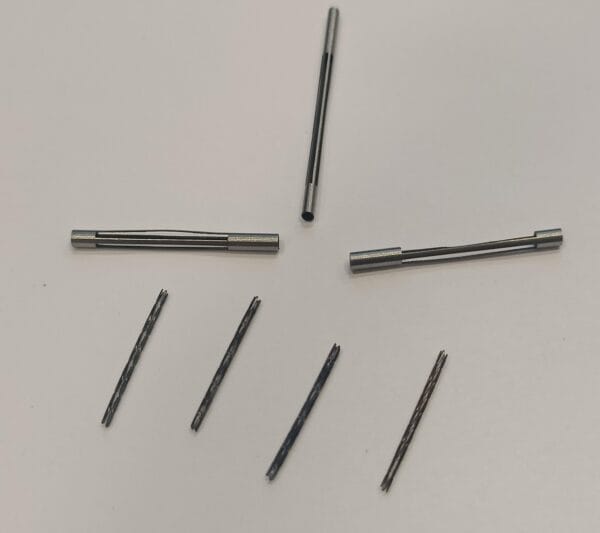

We manufacture high-performance nitinol hypotubes for life-saving medical applications. Our flagship micro-tube features an outer diameter (OD) of 0.1mm and a wall thickness of just 0.05mm—ideal for devices where size, strength, and flexibility are critical.

Why Nitinol? The Super-Alloy of Modern Medicine

Our nitinol hypotubes are made from a high-purity nickel-titanium alloy. This smart material is known for two exceptional properties:

Shape Memory: When deformed at cooler temperatures, nitinol “remembers” its original form and returns to it when heated.

Superelasticity: It bends and flexes without permanent deformation—making it ideal for intricate procedures inside the human body.

These unique features reduce device fatigue, minimize incision size, and enable safer, more precise interventions.

Precision Tube Specifications

We specialize in ultra-thin tubing that requires extreme accuracy:

Outer Diameter Range: 0.05mm to 2.0mm

Wall Thickness Range: 0.02mm to 0.2mm

Featured Size: OD 0.1mm / Wall 0.05mm

Every hypotube is cut using advanced laser systems, ensuring zero distortion and micrometer-level tolerance.

Nitinol Hypotube Applications

Catheters: Navigate narrow vessels during cardiac and neurological procedures

Guidewires: Direct instruments through arteries safely

Stent Delivery Systems: Deploy arterial support structures accurately

Minimally Invasive Robotics: Enable precision with ultra-small actuators

Neurology Devices: Treat nerve-related disorders with targeted delivery

Endoscopy Tools: Integrate with flexible scopes for diagnostic imaging

Frequently Asked Questions

1. How strong is your 0.1mm OD nitinol hypotube?

Despite its size, it offers excellent tensile strength and fatigue resistance. It won’t kink during critical procedures.

2. Can you provide custom tube sizes?

Absolutely. We offer tailored OD, ID, and wall thickness. Prototypes and sample runs are available.

3. What surface finishes are available?

Choose between polished, etched, or custom-textured finishes for optimal device integration.

4. Does nitinol resist corrosion?

Yes. It’s biocompatible and corrosion-resistant, ideal for long-term implantation.

5. Are your nitinol tubes certified for medical use?

Yes, they comply with ISO 13485 and ASTM F2063 standards. Each batch undergoes strict quality assurance.

6. How do you maintain dimensional precision?

We use laser micrometers and scanning electron microscopy to validate every tube’s dimensions.

7. Can nitinol hypotubes house electronics or optics?

Yes. Their hollow core accommodates micro-sensors, wires, or fiber optics.

8. Why choose your factory?

13+ years of experience in nitinol tube manufacturing

Zero-defect quality control

Fast international delivery

Full engineering and R&D support

Unlock Next-Generation Device Innovation

Looking for ultra-miniature nitinol hypotube solutions? Our 0.1mm OD tubes solve complex challenges in modern medical device design. They enable smaller incisions, faster recovery, and higher device intelligence.

Get in touch today! Share your specifications and receive expert support for your next innovation.

▸ Facebook account:Facebook

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolusa.com

Mid East Region:getnitinol.com

Reviews

There are no reviews yet.