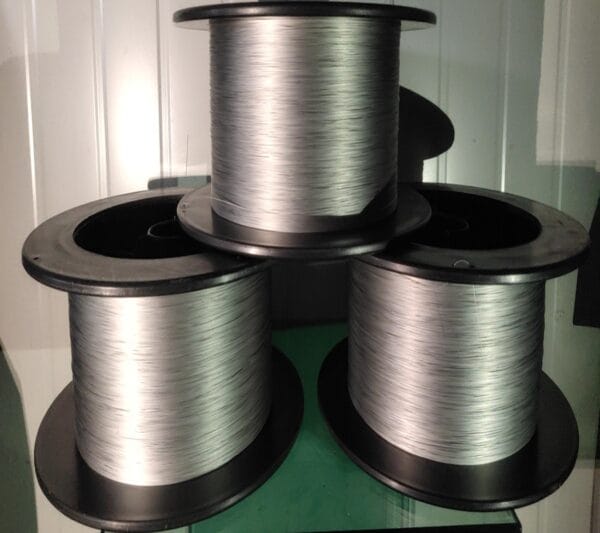

Nitinol Grinding Wire for Nitinol Guide Pins and Precision Applications

Advanced Material for Critical Performance

Our Nitinol grinding wire is engineered from a premium nickel-titanium alloy, specifically formulated for medical and high-precision uses. Containing 55% nickel and 45% titanium, this alloy provides exceptional flexibility, shape memory, and corrosion resistance. Whether under mechanical stress or extreme temperatures, Nitinol maintains structural integrity—bending and returning to its original form without deformation. These properties make it the perfect material for nitinol guide pins, surgical tools, and demanding industrial components.

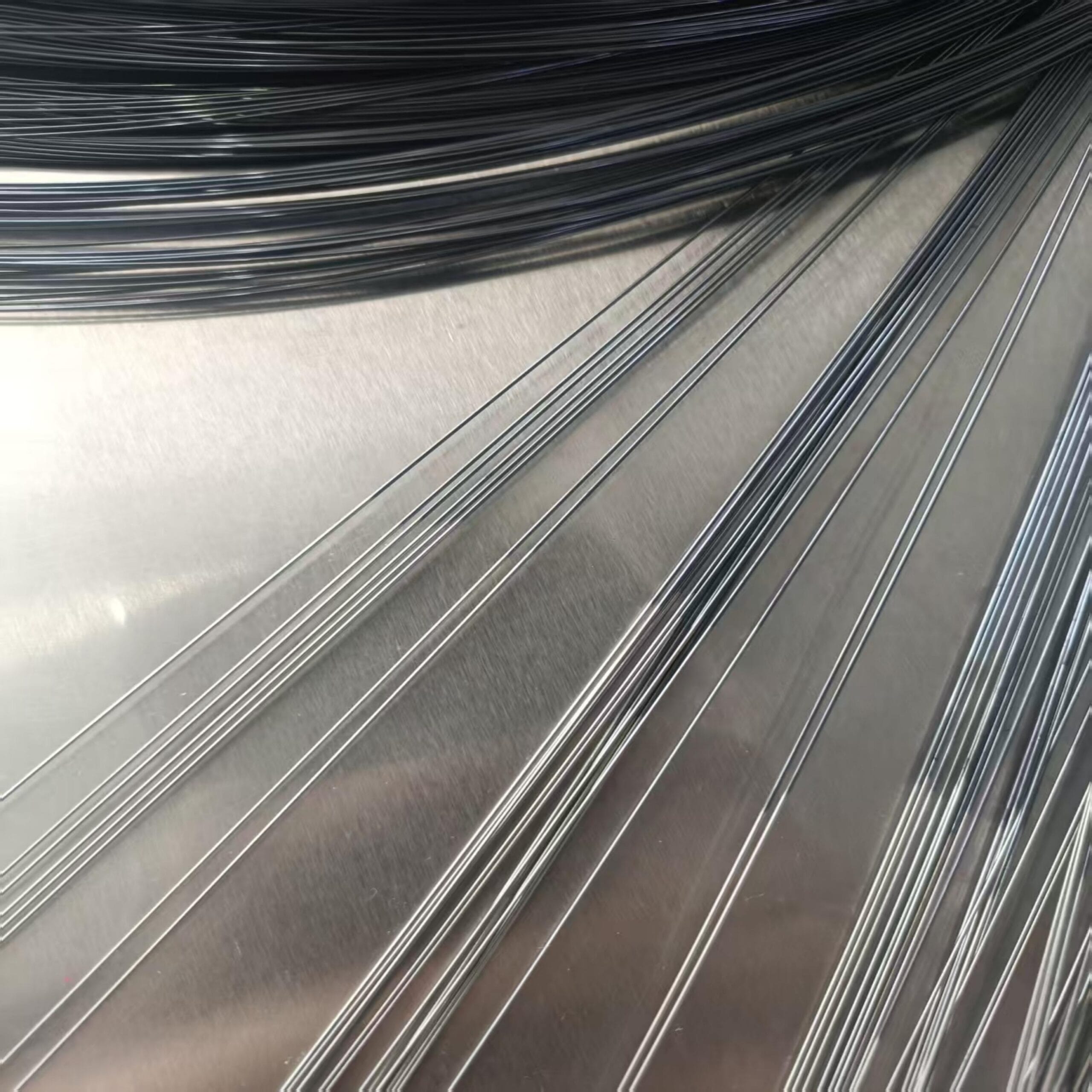

Ultra-Smooth Surface Finish

Each wire is precision-ground and mirror-polished to eliminate micro-defects and sharp edges. This smooth finish minimizes friction, enhances durability, and ensures seamless navigation through anatomical structures or tight mechanical channels. The flawless surface helps prevent tissue trauma, making it suitable for minimally invasive surgical procedures and intricate engineering tasks.

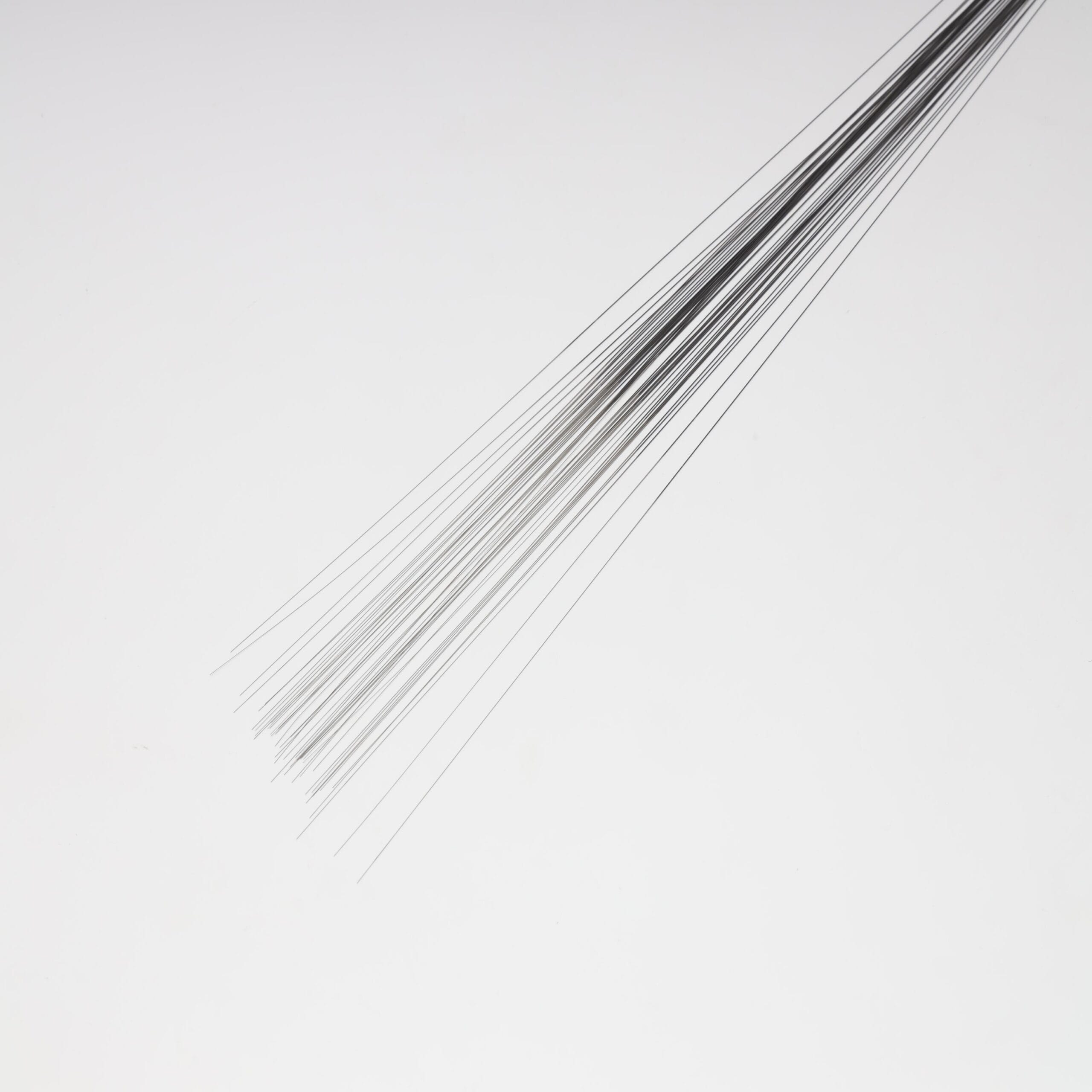

Versatile Diameter Options

We offer a wide range of diameters from 0.1 mm to 2.0 mm, ensuring compatibility with diverse applications—from delicate neurovascular interventions to robust orthopedic tools. Consistent diameter control across batches guarantees reliability and uniformity in nitinol guide pin performance. Customized sizes are available to meet your specific project demands.

Applications of Our Nitinol Grinding Wire

Medical Applications: Precision in Every Procedure

Our grinding wire serves as the core material for nitinol guide pins used in orthopedic, cardiovascular, and minimally invasive surgeries. Its elasticity and biocompatibility allow it to navigate complex anatomy with minimal trauma. Additionally, it is used in the production of stents, catheters, biopsy tools, and other endoscopic instruments that demand high flexibility and endurance.

Dental Applications: Trusted by Professionals

In dentistry, Nitinol wire plays a vital role in orthodontic braces, root canal files, and implant systems. Its gentle yet strong characteristics make it ideal for sensitive oral procedures where both strength and flexibility are required.

Industrial Applications: Reliable Under Pressure

Beyond the medical field, our Nitinol wire excels in precision grinding, aerospace engineering, robotics, and micro-mechanical systems. It is engineered to withstand extreme conditions including high pressure, friction, and temperature variations—making it ideal for high-performance tasks in challenging environments.

Why Choose Our Nitinol Wire for Your Guide Pin Projects?

Superior Flexibility & Strength

The wire bends, twists, and returns to shape under pressure, reducing the risk of breakage during procedures.Certified Biocompatibility

Meets ISO 10993 standards, ensuring safe integration with the human body for long-term medical use.Precision Manufacturing

Advanced grinding and laser-cutting technologies ensure exact specifications and minimal tolerance variation.Tailored to Your Needs

Customizable diameter, length, and surface finish options support rapid prototyping and product development.Fast Turnaround

We maintain an inventory of high-demand sizes and offer 48-hour shipping for fast project initiation.Technical Expertise

Our engineers provide application support, helping clients optimize wire use for nitinol guide pin production and beyond.Global Trust

Hospitals, labs, and manufacturers in over 20 countries rely on our wire for consistent, high-quality results.

Ready to elevate your next innovation?

Our Nitinol grinding wire combines unmatched flexibility, strength, and finish—making it the trusted choice for nitinol guide pins and other precision instruments. Contact our team today for a quote or sample.

Reviews

There are no reviews yet.