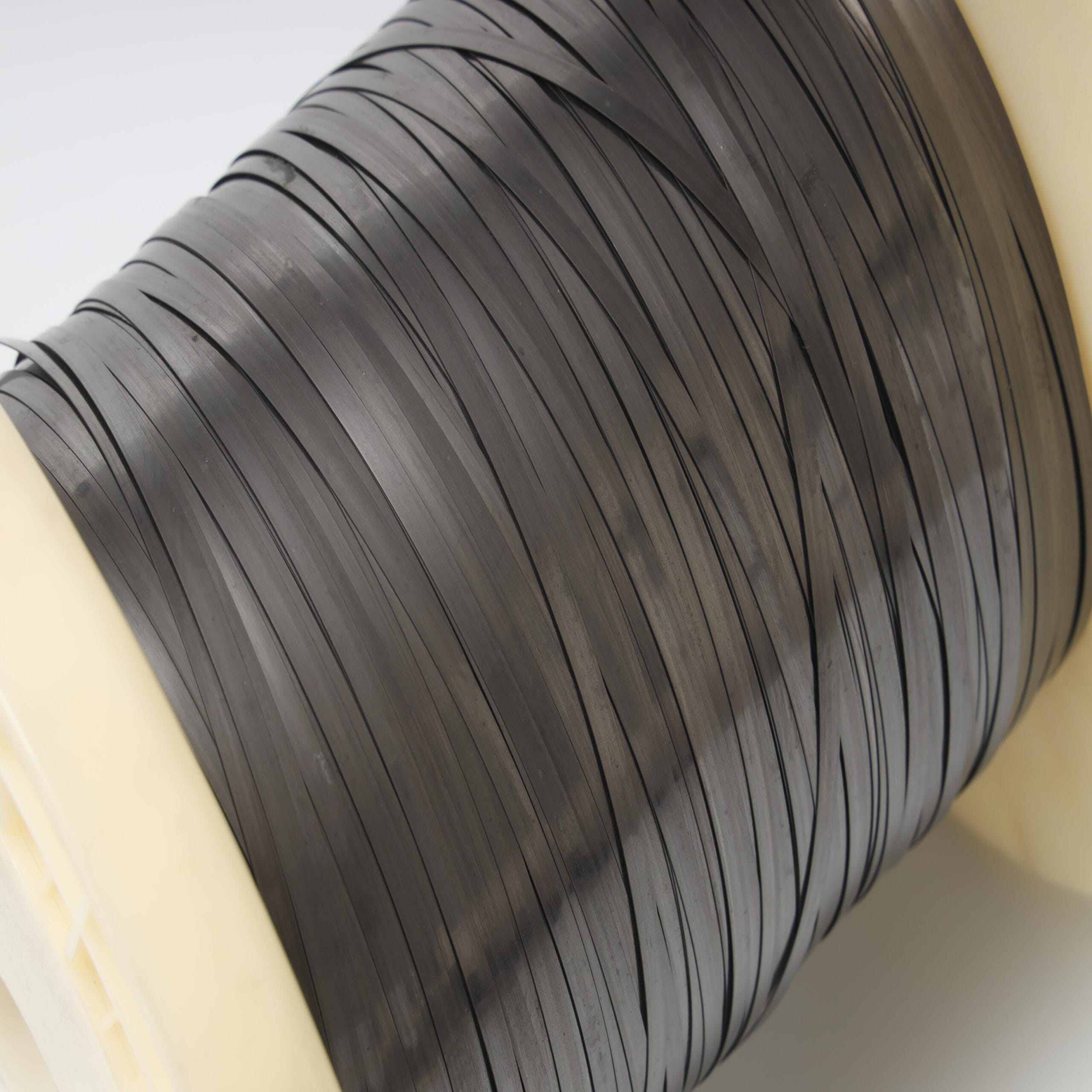

Unlocking Nitinol Flat Wire’s Transformative Potential

In the realm of advanced engineering, nitinol flat wire stands out as a revolutionary material reshaping industries ranging from healthcare to aerospace. As a nickel-titanium alloy, it offers remarkable shape memory and superelastic properties, enabling applications that demand both precision and adaptability. Whether it’s in life-saving implants or deployable satellite systems, this alloy has rapidly become a cornerstone of next-generation innovation.

Cross-Industry Innovation

Thanks to its unique characteristics, nitinol flat wire empowers engineers and designers to rethink conventional approaches across a variety of fields:

Medical Technology: Biocompatible and corrosion-resistant, it ensures consistent force in stents and orthodontic wires, thereby enhancing long-term patient outcomes.

Aerospace Systems: Its shape-memory behavior allows components like solar arrays and antennae to stay compact during launch, then expand reliably once deployed in orbit.

Robotic Actuation: Engineers incorporate it into micro-grippers and artificial muscles, where thermally activated motion effectively mimics biological functions.

Consumer Products: Due to its durability and flexibility, it’s used in eyeglass frames, watch springs, and wearable tech, offering both resilience and comfort.

Consequently, designers gain access to a smart material that adapts to its environment while maintaining structural integrity.

Engineering Advantages of Nitinol Flat Wire

Nitinol flat wire provides several engineering advantages that make it suitable for demanding applications:

First, its biocompatibility makes it ideal for long-term implantation in FDA-approved medical devices.

Second, it demonstrates outstanding fatigue resistance, withstanding over 10 million stress cycles without performance loss.

Third, the alloy’s thermal responsiveness enables it to return to a programmed shape with pinpoint accuracy at specific temperatures.

Taken together, these traits create a dependable solution where traditional metals may degrade or fail under similar conditions.

Precision in Manufacturing

The production of nitinol flat wire involves meticulous control to ensure consistent performance:

Initially, vacuum arc melting produces high-purity nickel-titanium ingots.

These ingots are then hot-rolled into intermediate forms suitable for further shaping.

Subsequently, cold working reduces the cross-sectional area by 40–50%, enhancing mechanical strength.

Shape-setting heat treatments, typically conducted between 400°C and 600°C, train the alloy to “remember” a specific geometry.

Finally, electropolishing delivers ultra-smooth surfaces ideal for medical-grade use, reducing both friction and bacterial adhesion.

Each stage contributes to dimensional stability and long-term reliability.

Comprehensive Quality Control

To meet rigorous industry and medical standards, manufacturers apply a variety of quality assurance protocols:

Rotary beam fatigue testing validates performance under repeated stress up to 10 million cycles.

Differential scanning calorimetry (DSC) ensures that transformation temperatures are precisely tuned.

Scanning electron microscopy (SEM) evaluates surface finish and internal microstructure.

ISO 13485 certification guarantees compliance with global medical manufacturing practices.

Through this multilayered approach, every batch of nitinol flat wire is verified for high-stakes deployment.

A Material Designed for Sustainability

Beyond its performance capabilities, nitinol flat wire supports sustainable engineering goals:

Notably, it is fully recyclable without degradation of its physical properties.

Moreover, its shape-memory activation requires only short bursts of heat—no ongoing power source—resulting in reduced energy usage.

Additionally, its extended service life minimizes the need for frequent replacements, thereby cutting down on material waste.

As a result, the alloy plays a vital role in eco-conscious product design without compromising performance.

Future Development Frontiers

As research and development efforts accelerate, nitinol flat wire is enabling breakthroughs in areas once thought impractical:

Cardiovascular implants with ultra-thin, self-expanding designs are improving patient outcomes while reducing recovery time.

Morphing aircraft wings that dynamically reshape in flight are enhancing aerodynamic efficiency and reducing fuel consumption.

Smart textiles, capable of regulating body temperature in real time, are transforming the wearables sector.

Reusable space systems, including adaptive docking mechanisms, are extending mission capabilities while reducing cost.

In short, nitinol flat wire is cementing its place as a foundational material in the future of engineering—blending adaptability, efficiency, and sustainability into one powerful solution.

Prototyping Support

▸ Trial Kits: 10-size assortment (0.1-1.0mm)

▸ Material Analysis: Complimentary DSC testing

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolusa.com

Mid East Region:getnitinol.com

Back to the products

Reviews

There are no reviews yet.