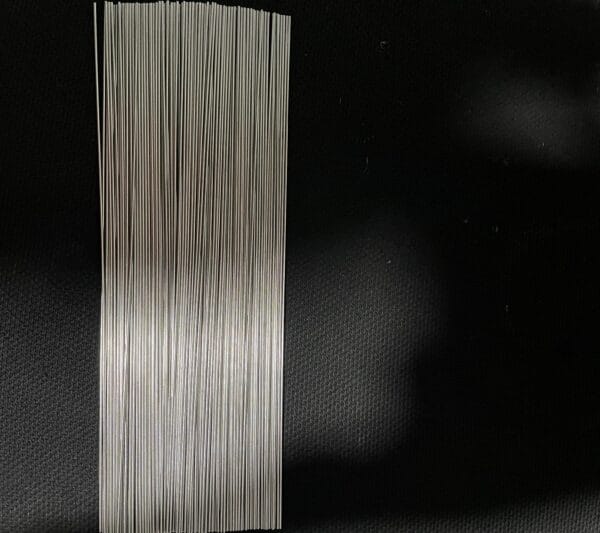

Master Metalwork with Nitinol Flat Tubes: Strength Meets Precision

Achieve next-level metalwork precision with our expertly crafted Nitinol Flat Tubes. Engineered from high-grade nickel-titanium alloy and produced with advanced manufacturing expertise, these flat tubes deliver outstanding durability, dimensional consistency, and high-performance capabilities.

Engineered Alloy: Nitinol’s Shape Memory & Superelasticity Metalwork

Our flat tubes are built around Nitinol—an exceptional nickel-titanium alloy recognized for its two revolutionary characteristics:

Superelasticity: The tube bends under extreme stress and instantly returns to its original flat profile – no permanent deformation.

Shape Memory: After deformation, a simple heat cycle restores the tube to its predefined shape, enabling self-actuating functionality.

These properties, combined with resistance to fatigue, temperature shifts, and corrosion, make Nitinol superior to conventional metals in modern metalwork.

Premium Surface Finishes: Built for Application Readiness Metalwork

Choose from a wide range of surface finishes tailored for specific industrial and medical applications:

Bright mirror finish: Reduces surface friction, making it well-suited for medical applications.

Matte finish: Offers excellent coating adhesion and clean aesthetics.

Chemically etched finish: Ensures stronger bonding with surface treatments.

Controlled oxide finish: Delivers consistent roughness for technical integration.

All finishes undergo strict quality checks for cleanliness, smoothness, and functional readiness.

Tailored Sizes with Exceptional Precision

Precision manufacturing guarantees that every Nitinol Flat Tube achieves outstanding dimensional consistency:

Outer width range: 0.1 mm (0.004″) up to 10.0 mm (0.394″)

Thickness options span from an extremely thin 0.05 mm (0.002″) to a strong and durable 1.0 mm (0.039″)

For projects with specialized metalwork needs, we offer full customization in both size and tolerance.Our production process ensures every tube offers reliable, consistent outcomes across all manufacturing batches.

Built for Demanding Applications

Our Nitinol Flat Tubes are trusted across industries:

Medical Devices: Ideal for stents, guidewires, and surgical tools.

Aerospace & Defense: Used in actuators, adaptive structures, and sensors.

Fluid Systems: Resists kinks and corrosion in chemical environments.

Electronics & MEMS: Functions as actuators and precision springs.

Energy Sector: Supports tools and thermal actuators.

Industrial Machinery: Delivers fatigue resistance and long service life.

Why Choose Our Nitinol Flat Tubes?

Unmatched Flexibility & Strength

Reliable Shape Memory Recovery

Long-Term Fatigue Resistance

High Thermal & Corrosion Tolerance

Medical-Grade Biocompatibility

Precision Manufacturing with Certified Purity

Full Customization & Expert Engineering Support

Advance Your Metalwork Projects Today

Whether you’re designing for aerospace, medical, industrial, or robotic systems, our Nitinol Flat Tubes provide the advanced material solution you need. Contact us today to unlock the future of metalwork with precision, strength, and innovation built into every tube.

▸ Expert Guidance: 24/7 support via nitinolalloy.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.