Nitinol Based Guide Wire Market: Precision Tools for Modern Medicine

Welcome to the forefront of minimally invasive technology. We specialize in nitinol based guide wire market solutions designed for physicians who demand precision, control, and patient safety. Our advanced guide wires represent the next generation of medical tools, delivering unmatched flexibility and reliability.

The Magic Material: Nitinol

Nitinol is a remarkable alloy made of nickel and titanium. This unique blend grants nitinol two extraordinary properties: Shape Memory and Superelasticity. Shape Memory allows the wire to return to its original form after deformation when gently heated. Superelasticity enables it to bend far more than conventional metals without permanent damage, ensuring durability and performance inside the human body.

Where Nitinol Excels in Medicine

Due to its flexibility, biocompatibility, and strength, nitinol has become the preferred material in many life-saving devices, such as:

Guide Wires – Navigating delicate vessels with accuracy.

Stents – Restoring blood flow in arteries.

Filters – Capturing harmful clots.

Dental Archwires – Straightening teeth effectively.

Orthopedic Devices – Supporting bone repair.

Surgical Tools – Offering precision and flexibility.

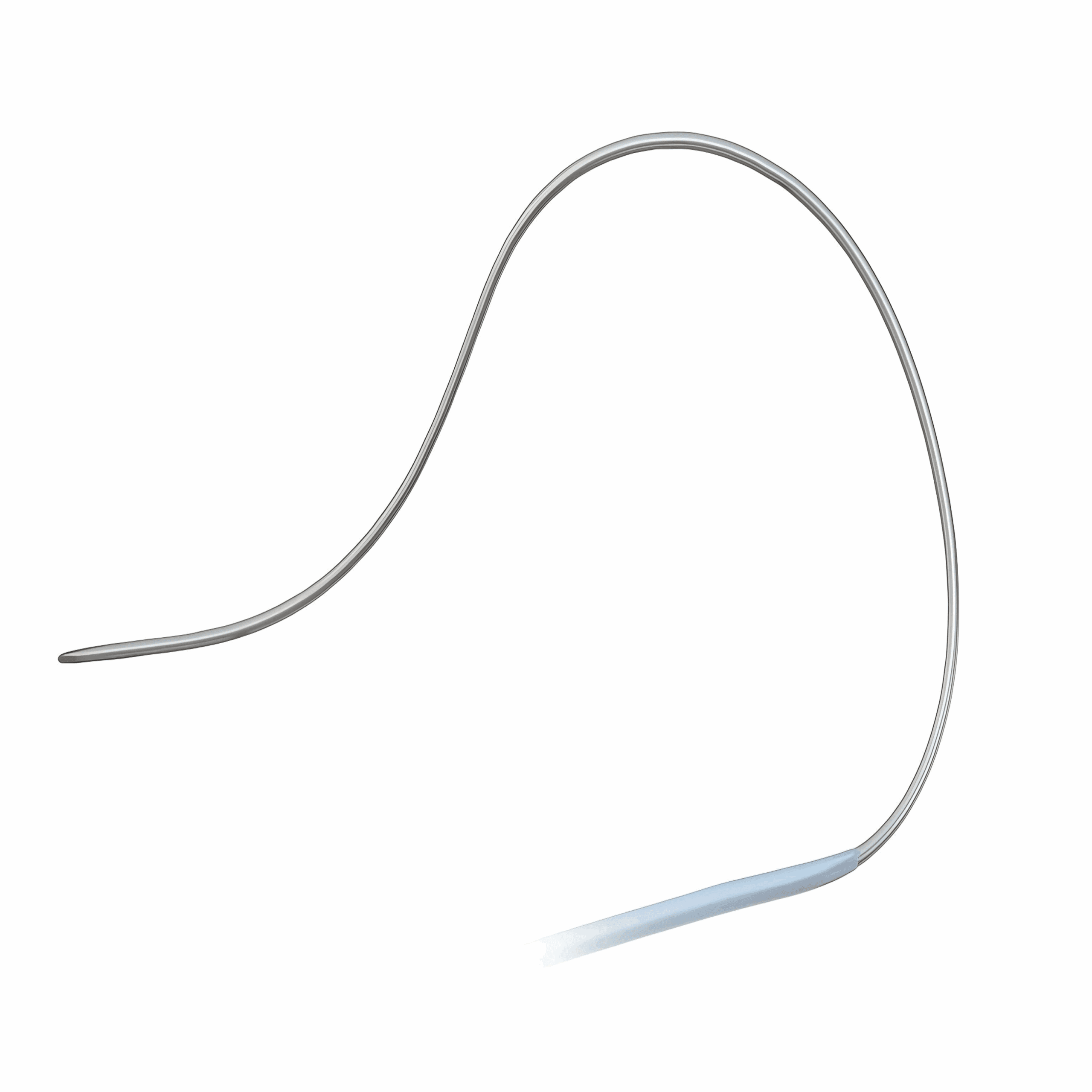

What is a Nitinol Guide Wire?

A nitinol guide wire is a slender yet powerful roadmap for minimally invasive procedures, including angiography and stent placement. Inserted first, it carefully navigates through complex anatomy. Once positioned, it acts as a rail for catheters, stents, or other instruments. Our nitinol based guide wires provide:

Unmatched Flexibility – Navigate sharp curves without kinking.

Steerability & Torque Control – Direct the tip with precision.

Smooth Glide – Low-friction coatings ensure safe passage.

Shape Memory & Biocompatibility – Reliable performance inside the body.

How We Manufacture Guide Wires

Producing premium guide wires demands advanced engineering:

Material Excellence – We use high-purity, medical-grade nitinol alloy.

Shaping the Core – Extrusion processes create ultra-fine diameters.

Tapering & Tip Forming – Grinding and machining achieve optimal tip designs.

Surface & Coating – Polishing plus PTFE or hydrophilic coatings reduce friction.

Rigorous Testing – Every wire undergoes diameter, tensile, and biocompatibility checks.

Sterile Packaging – Ethylene Oxide or Gamma sterilization ensures clinical safety.

Why Choose Our Nitinol Guide Wires?

We combine deep material science expertise with precision manufacturing to serve the nitinol based guide wire market. With multiple tip styles, diameters, and coating options, we offer solutions tailored to diverse clinical needs. Our mission is clear: to provide physicians with reliable, high-performance tools that improve patient outcomes.

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolalloy.com

Mid East Region:getnitinol.com

Reviews

There are no reviews yet.